Powder containing lump ore conveying system

A technology for conveying system and powder blocks, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of high powder content in the lump ore entering the furnace, increased cost of blast furnace ironmaking, and affecting the stability of the blast furnace. Achieve the effect of increasing the ratio of furnace input and reducing the cost of blast furnace ironmaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

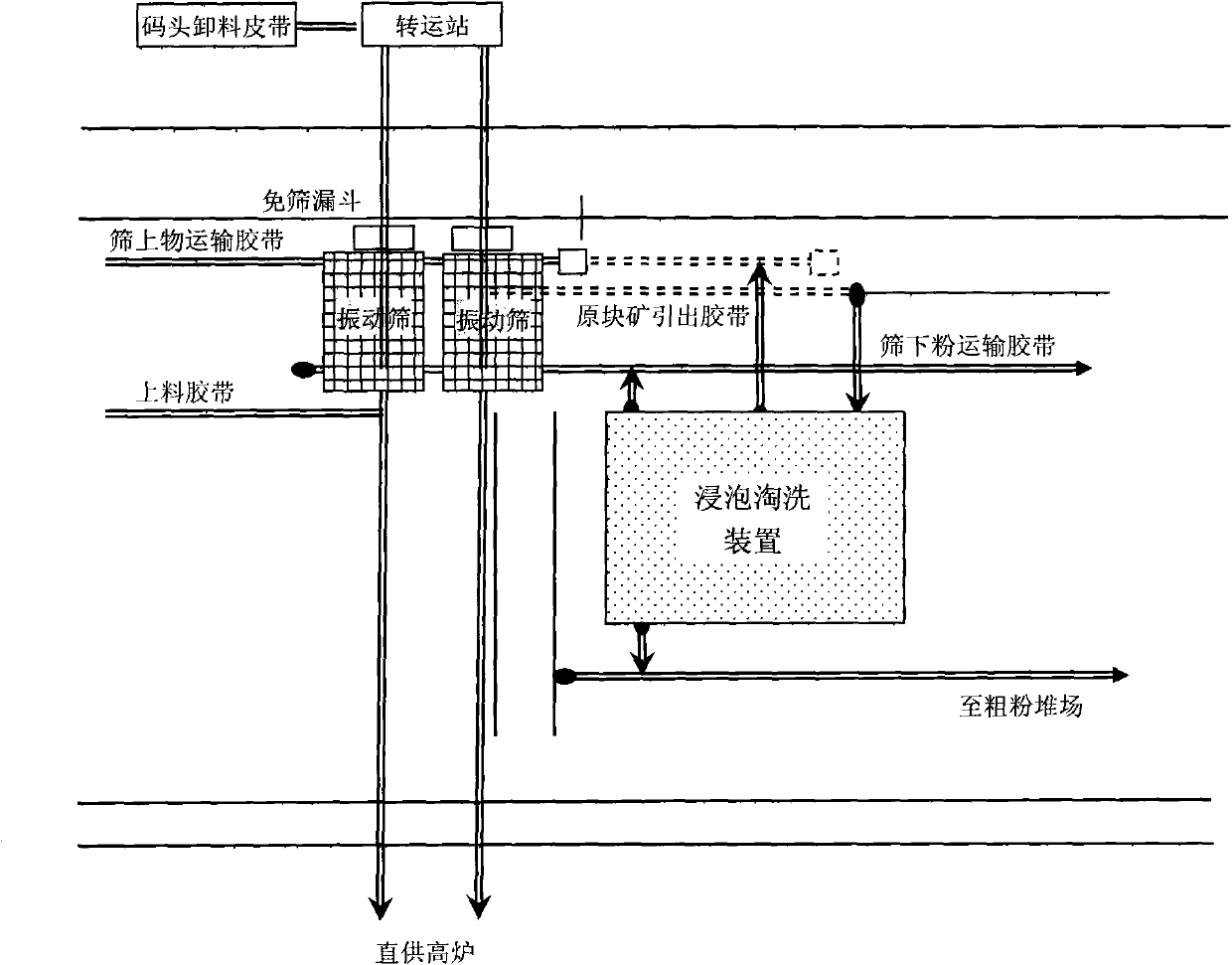

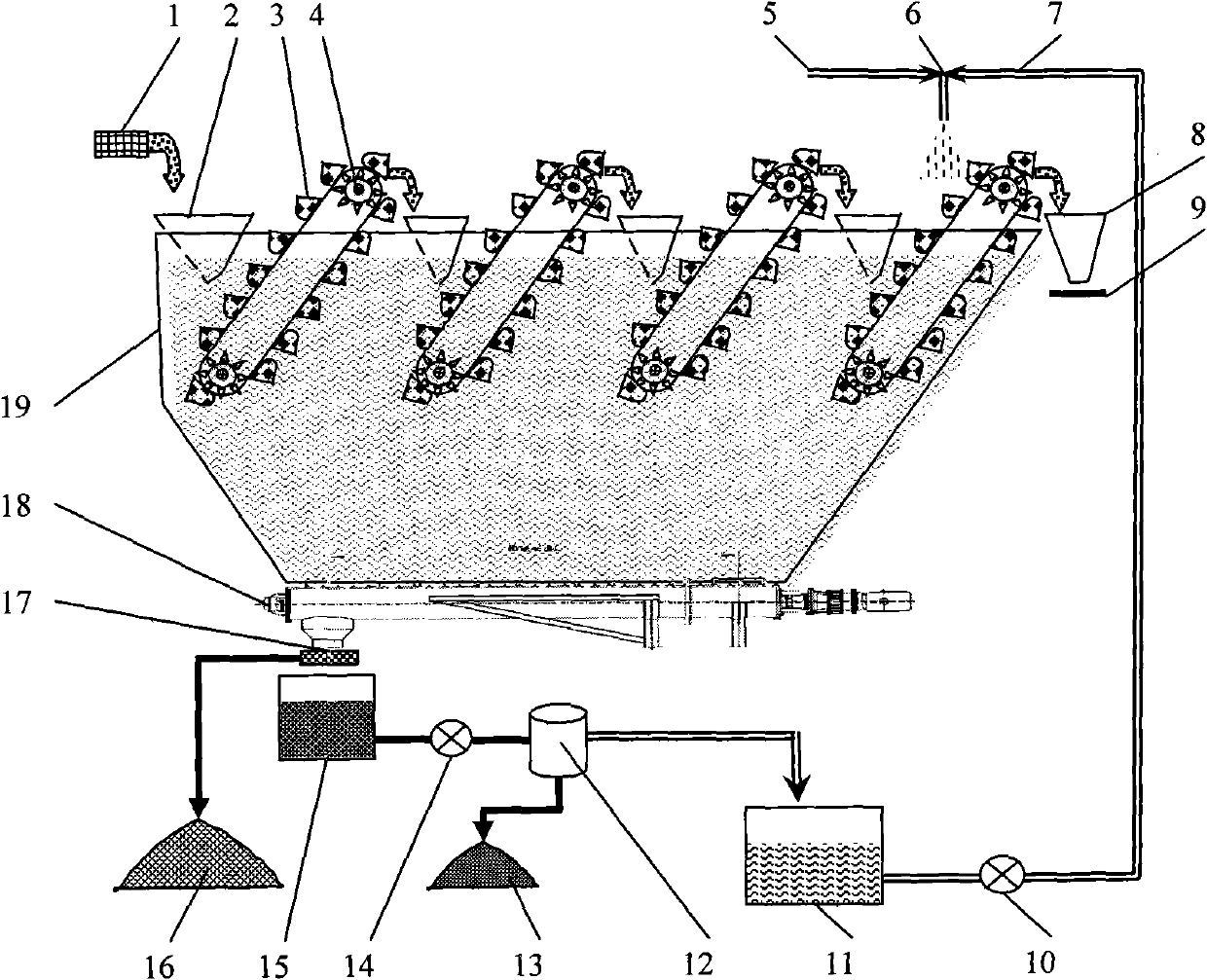

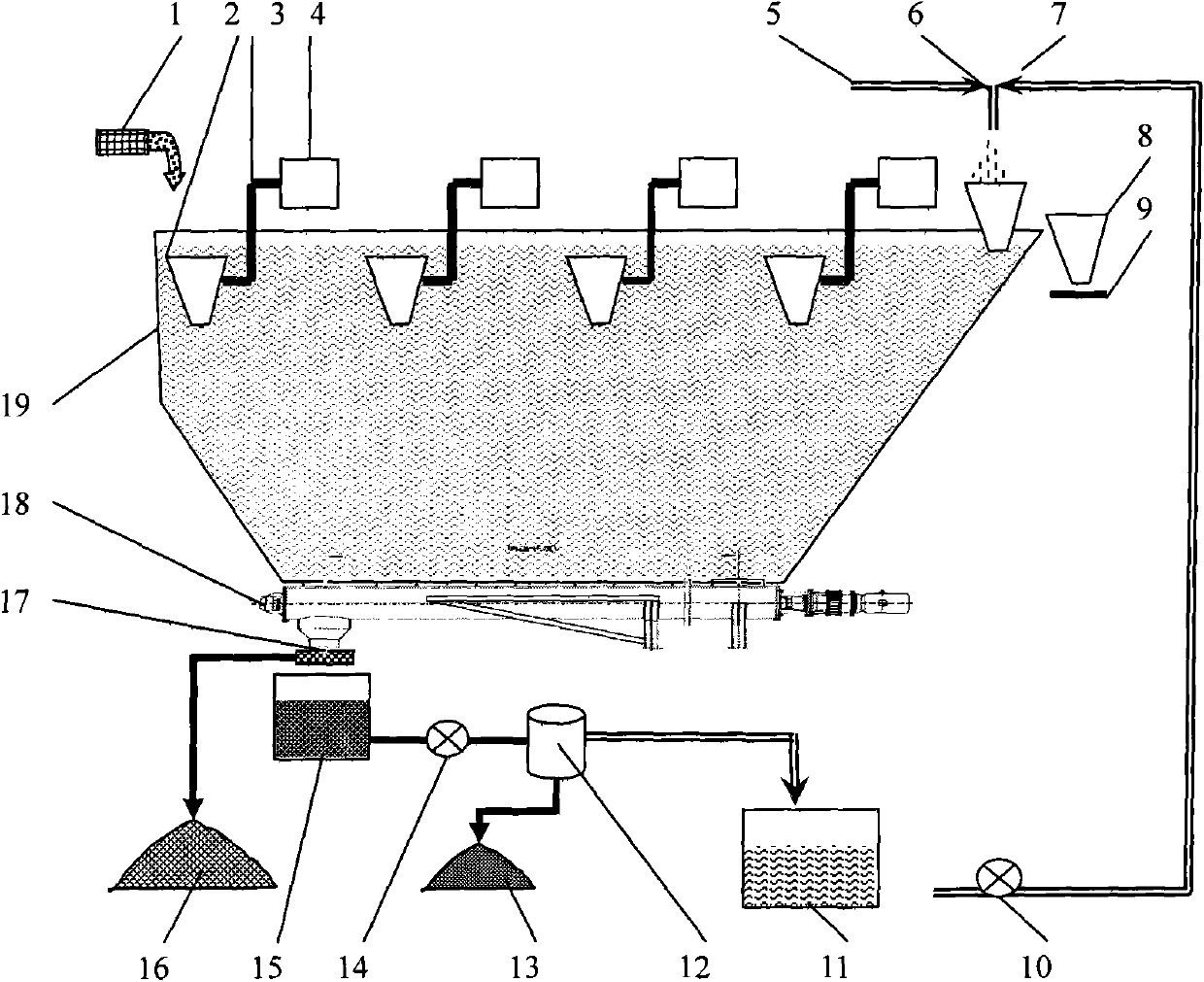

[0020] Depend on figure 1 It can be seen that the powder-containing lump ore is transported to the transfer station through the unloading belt of the dock, and the moisture content and powder content are measured at the transfer station. When the powder content reaches the requirements for entering the blast furnace, the powder-containing lump ore is directly transported to the sieve-free funnel; When the powder content rate does not meet the requirements of blast furnace feeding and the water content is less than 4%, the powder-containing lump ore is transported to the vibrating screen for screening, the lump ore on the screen is sent to the blast furnace, and the powder ore under the screen is sent to sintering or pelletizing Or pelletizing; when the powder content rate does not meet the blast furnace requirements and the water content is greater than 4%, the powder-containing lump ore is sent to the soaking elutriation device, and the viscosity of the powdery material is red...

Embodiment 2

[0024] Depend on figure 1 It can be seen that the powder-containing lump ore is transported to the transfer station through the unloading belt of the dock, and the moisture content and powder content are measured at the transfer station. When the powder content reaches the requirements for entering the blast furnace, the powder-containing lump ore is directly transported to the sieve-free funnel; When the powder content rate does not meet the requirements of blast furnace feeding and the water content is less than 4%, the powder-containing lump ore is transported to the vibrating screen for screening, the lump ore on the screen is sent to the blast furnace, and the powder ore under the screen is sent to sintering or pelletizing Or pelletizing; when the powder content rate does not meet the blast furnace requirements and the water content is greater than 4%, the powder-containing lump ore is sent to the soaking elutriation device, and the viscosity of the powdery material is red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com