Method for preventing self-fluxed pellets from bonding in roasting

A self-fluxing, pelletizing technology, applied in the field of ironmaking raw material production, can solve the problem of not well-solved high basicity pellet cohesiveness and other problems, achieve difficult cohesion, optimize charge structure, and increase charging The effect of proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Describe below in conjunction with specific embodiment:

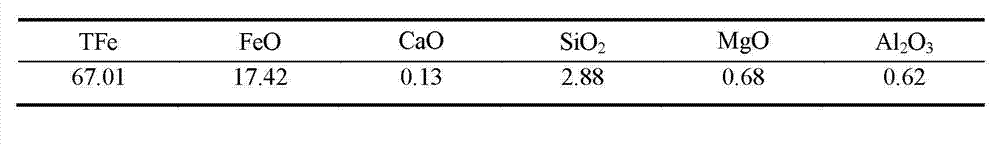

[0022] The mixed ore was used to carry out the self-melting pelletizing test, and the composition of the mixed ore is shown in Table 1.

[0023] Table 1 Mass percentage of mixed ore components

[0024]

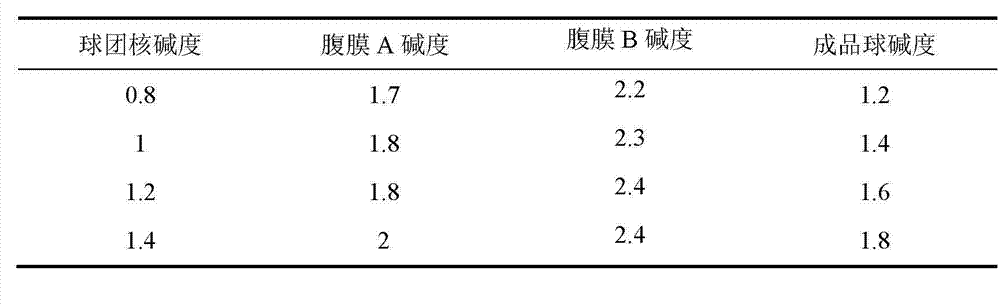

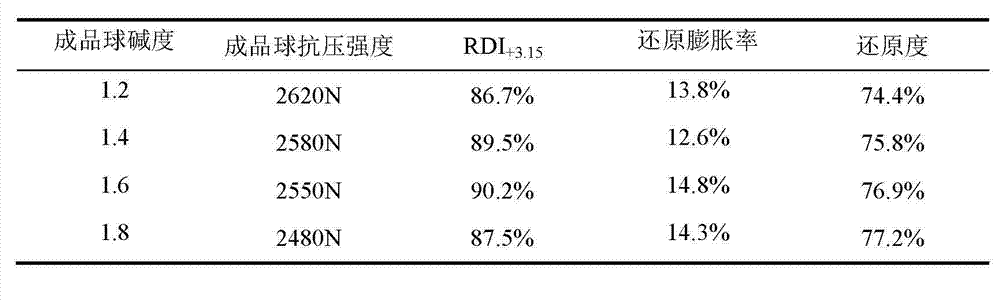

[0025] Fix the iron material, add flux and binder to make a mixture, the flux in the mixture is magnesite and lime powder, and the mass fraction of magnesite is 2%; the binder is bentonite; adjust the lime powder content so that The alkalinity of the mixture is 0.8, mix the mixture evenly, and pile it up for 30~40 hours. Then use a pelletizing machine to make the mixture into a self-fluxing pellet core with a particle size of 8-10 mm.

[0026] Mix dolomite powder and iron boron fine powder evenly to make anti-adhesion peritoneum A, wherein the alkalinity of anti-adhesion peritoneum A is adjusted to 1.7 according to the alkalinity of the self-fluxing pellet core; lime powder, iron phosphorus and carboxymethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com