A Method of Adding Steel Scrap in Large Proportion to Blast Furnace

A blast furnace and steel scrap technology, which is applied in the field of iron and steel smelting, can solve the problems of poor economic and technical indicators of blast furnaces, hinder the development of edge airflow, and bond the blast furnace body, achieve good air permeability index, small distribution influence, and reduce blast furnace energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A domestic ironmaking A blast furnace (2516m 3 )

[0047] Step 1: Add scrap steel bucket and scrap steel weighing bucket in the open place under the tank, and add belt 1 and belt 2 respectively between the scrap steel bucket and scrap steel weighing bucket, and between the scrap steel weighing bucket and the main belt;

[0048] Step 2: A blast furnace crushed steel scrap load is 4.9t, coke is loaded with 0.8t, and the two are fully mixed; the scrap steel is transported from the scrap steel hopper to the scrap steel weighing hopper through the additional belt 1, and then through the additional belt 2 directly onto the main belt;

[0049] A blast furnace usually adopts a batch weight of 70t;

[0050] Step 3: Blast furnace A adopts the method of feeding lump ore into the furnace in batches, and the order of distribution is: coke, sintering + jaw ball + South African block, scrap steel + coke diced; the ratio of scrap steel consumption to ore batch mass is 7:100;

[0051...

Embodiment 2

[0054] A domestic ironmaking A blast furnace (2516m 3 )

[0055] Step 1: Add scrap steel bucket and scrap steel weighing bucket in the open place under the tank, and add belt 1 and belt 2 respectively between the scrap steel bucket and scrap steel weighing bucket, and between the scrap steel weighing bucket and the main belt;

[0056] Step 2: The amount of crushed blast furnace steel scrap is 10.5t, and the amount of coke is 1.5t. The two are fully mixed; added to the main belt;

[0057] A blast furnace usually adopts a batch weight of 70t;

[0058] Step 3: Blast furnace A adopts the method of feeding lump ore into the furnace in batches, and the order of distribution is: coke, sintering + jaw ball + South Africa block, scrap steel + coke diced; the ratio of the amount of scrap steel to the mass of ore batch is 3:20;

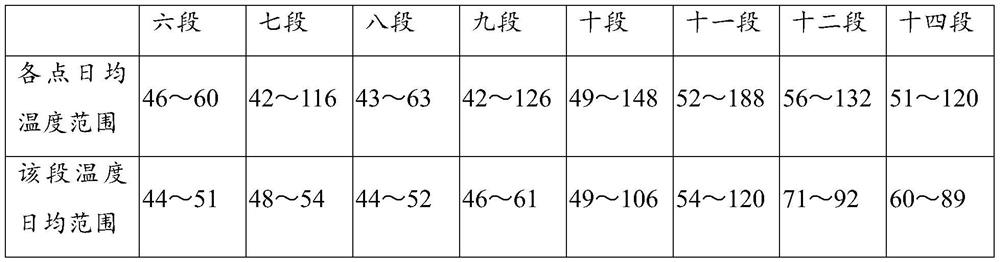

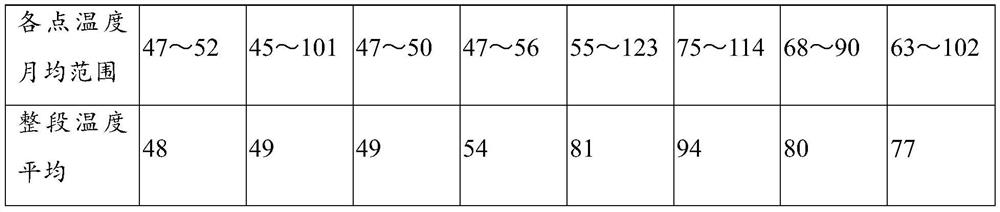

[0059] A blast furnace adopts the distribution matrix from the outer ring to the inner ring, and the charging matrix is: Among them, C is coke, O is sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com