A kind of production method of sintered ore containing high crystal water lump ore

The invention relates to a technology of high crystalline water lump ore and production method, which is applied in the production field of sintered ore, and can solve the problems of high crystallization water content, blockage of gas flow channels, thick furnace wall, etc., so as to improve the high-temperature metallurgical performance and increase the ratio of charging into the furnace. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

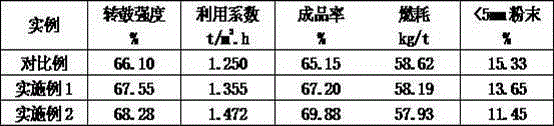

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment.

[0020] Due to the severe thermal bursting of high crystallized water lump ore, generally no more than 5% of the high crystallized water lump ore is directly put into the furnace during production. Furnace ratio increased to 20%. Increasing the proportion of cheap lump ore into the furnace can greatly reduce the production cost of the blast furnace.

[0021] Two commonly used iron ores for sintering with 50% concentrate + 50% powder ore are used. High crystal water lump ore is selected with crystal water content of 8.93%. The comprehensive alkalinity of sinter mixture and lump ore is set to 2.0, MgO Content 1.9%.

[0022] Due to the incompatibility between the large-sized lump ore and the sinter mixture, it will lead to the alkalinity segregation of the finished sintered ore, that is, the local alkalinity of the sintered ore except the lump ore is high. When 10% of the lump ore is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com