Iron ore pellet iron-rich composite binder and its preparation method and use

A technology of iron ore pellets and binders, which is applied in the field of iron ore pellet binders, can solve the problems of reducing the iron grade of finished pellets, improve the quality of finished pellets, improve the performance of pellets, and reduce the total cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly understand the content of the present invention, specific examples will be used for further introduction.

[0025] According to the survey, iron slime is an industrial by-product, and the annual output is relatively large. There are 500,000 to 800,000 tons in Shandong and Shanxi provinces in my country every year, and the project price is very cheap. Since iron slime is a resource regeneration and environmental protection project, how to effectively and environmentally friendly use iron slime is of great significance to environmental protection.

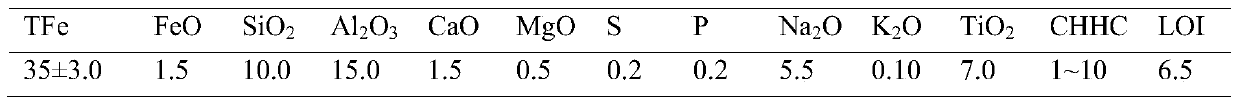

[0026] The embodiment of the present invention selects a kind of iron slime, wherein iron grade is 30~40wt%, (SiO 2 +Al 2 o 3 ) content<25%, the water content is about 30wt%, and the particle size is less than 140 mesh.

[0027] The steps of preparing the iron ore pellet iron-rich composite binder by using this iron slime raw material are as follows:

[0028] Firstly, dry and finely grind the iron mud c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com