A kind of alkaline pellet preparation method and its preparation and used mineral powder mixture

A technology of alkaline pellets and mixtures, which is applied in the field of blast furnace metallurgy, can solve the problems of low proportion of pellets used, and achieve the effects of improving blast furnace smelting indicators, increasing alkalinity, and increasing the proportion of furnace input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

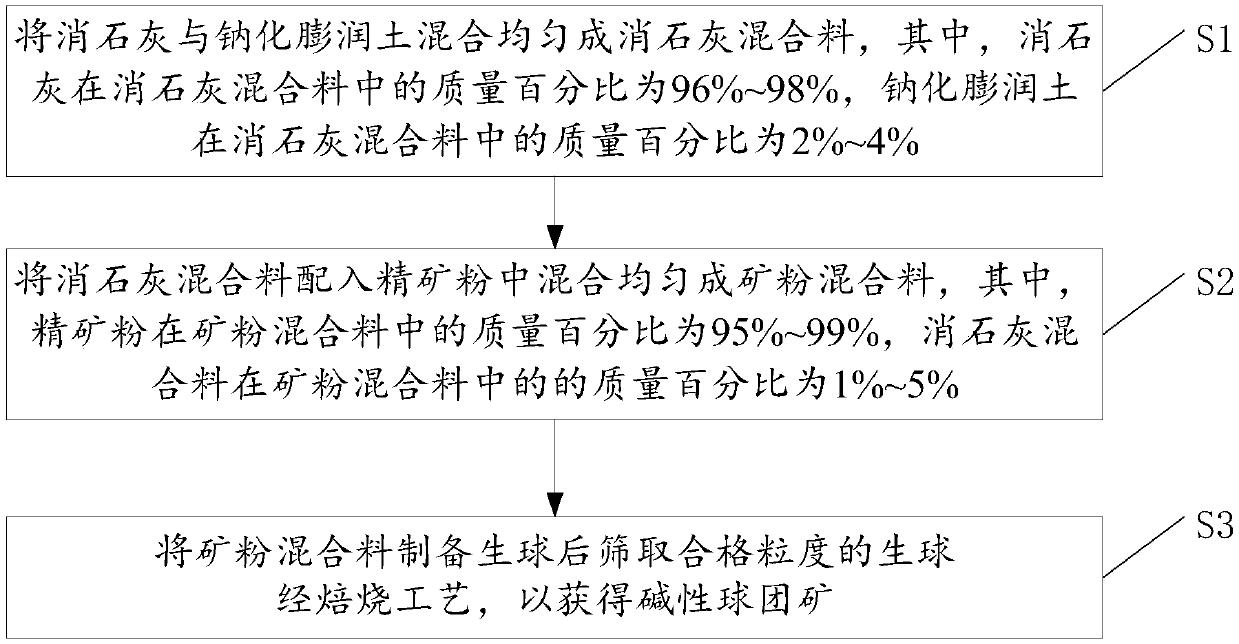

[0017] The embodiment of the present invention provides a method for preparing alkaline pellets, which is applied to the preparation of alkaline pellets. refer to figure 1 As shown, the method for preparing alkaline pellets provided by the embodiments of the present invention comprises the following steps:

[0018] S1. Mix hydrated lime and sodium bentonite evenly to form a hydrated lime mixture, wherein the mass percentage of hydrated lime in the hydrated lime mixture is 96% to 98%, and the mass percentage of sodium bentonite in the hydrated lime mixture is 2% to 4%. .

[0019] Specifically, in S1: First, according to the mass ratio of slaked lime and sodium bentonite (96-98): (4-2), weigh the slaked lime and sodium bentonite, and mix the weighed slaked lime and sodium bentonite evenly to form slaked lime Mixture.

[0020] Concrete, the Ca(OH) of the slaked lime used in the present embodiment 2 Content > 92%, particle size ≤ 44μm content ≥ 90%. The water absorption rate ...

Embodiment 1

[0031] Slaked lime and sodium bentonite are mixed uniformly at a mass ratio of 96:4 to form a slaked lime mixture, and then the concentrate powder is mixed with the prepared slaked lime mixture at a mass ratio of 95:5 to form a mineral powder mixture, and then mixed with water to form a uniform mixture. Adjust the moisture content of the mineral powder mixture to 7.3%. For example, take 0.288kg of slaked lime and 0.012kg of sodium bentonite and mix them uniformly to form a slaked lime mixture, then mix the prepared slaked lime mixture into 9.7kg of weighed concentrate powder and mix evenly into the ore-forming powder mixture.

[0032] The mineral powder mixture is made into green balls in the disc pelletizer for 12 minutes. After the green balls are made, sieve the green balls with a particle size of 9-16mm, and use a roasting cup to process the sieved green balls with a particle size of 9-16mm as follows: Roasting process: The raw balls are air-dried at 330°C for 3 minutes, t...

Embodiment 2

[0038] Slaked lime and sodium bentonite are mixed uniformly at a mass ratio of 98:2 to form a slaked lime mixture, and then the concentrate powder is mixed with the prepared slaked lime mixture at a mass ratio of 99:1 to form an ore-forming powder mixture, and then mixed with water to form a uniform mixture. Adjust the moisture content of the mineral powder mixture to 7.5%. For example, 0.343kg of slaked lime and 0.007kg of sodium bentonite are weighed and mixed uniformly to form a slaked lime mixture, and then the prepared slaked lime mixture is mixed into the weighed 9.75kg of concentrate powder and mixed evenly into the ore-forming powder mixture.

[0039] The mineral powder mixture is made into green balls in the disc pelletizer for 12 minutes. After the green balls are made, sieve the green balls with a particle size of 9-16mm, and use a roasting cup to process the sieved green balls with a particle size of 9-16mm as follows: Roasting process: The raw balls are air-dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com