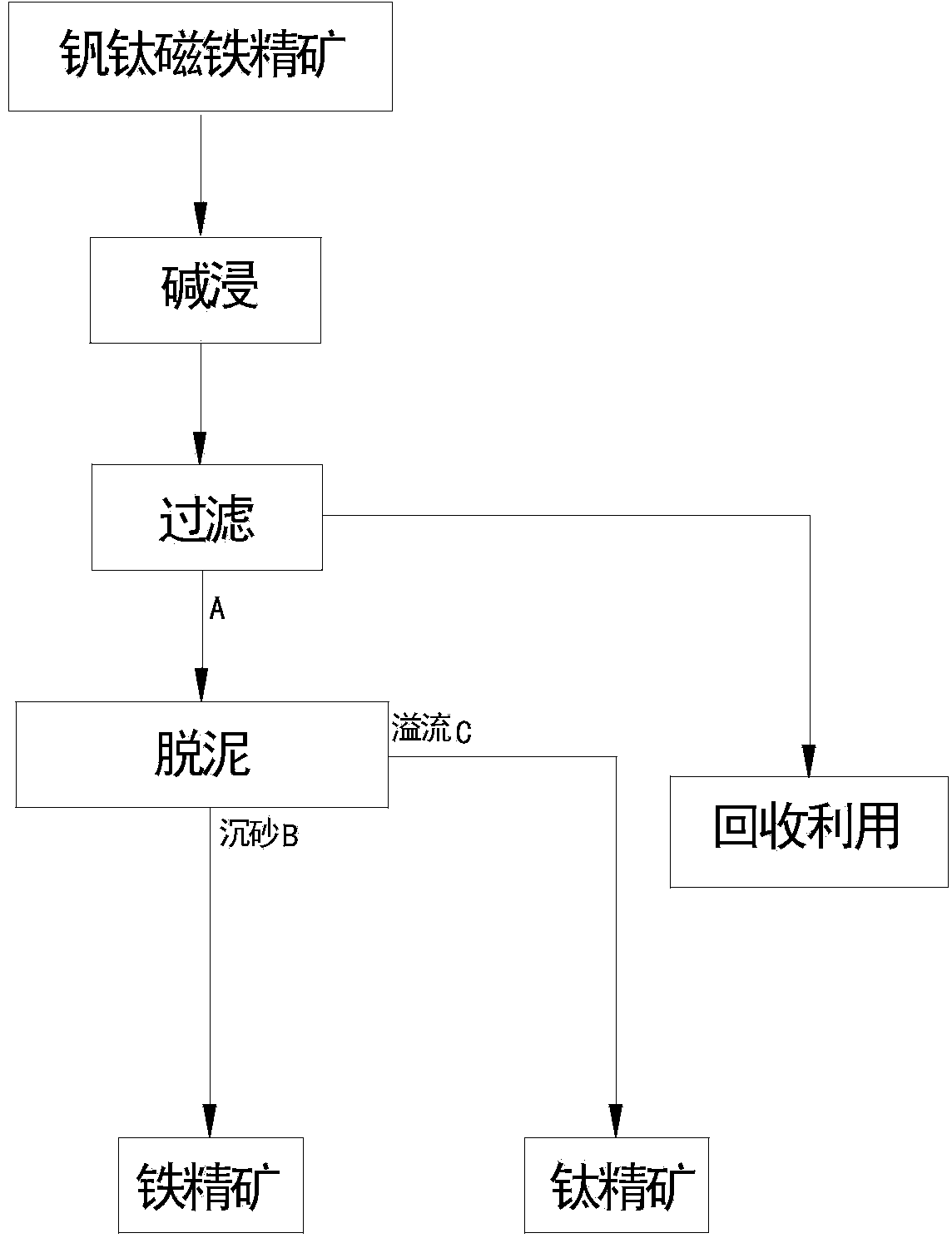

Method for recleaning vanadium titanium magnetite concentrate by using alkaline leaching and desliming

A vanadium-titanium magnetite concentrate and alkali leaching technology, which is applied in the field of alkali leaching, desliming and re-selection of vanadium-titanium magnetite concentrate, to achieve the effects of reducing emissions, improving blast furnace utilization coefficient, and improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Alkaline leaching

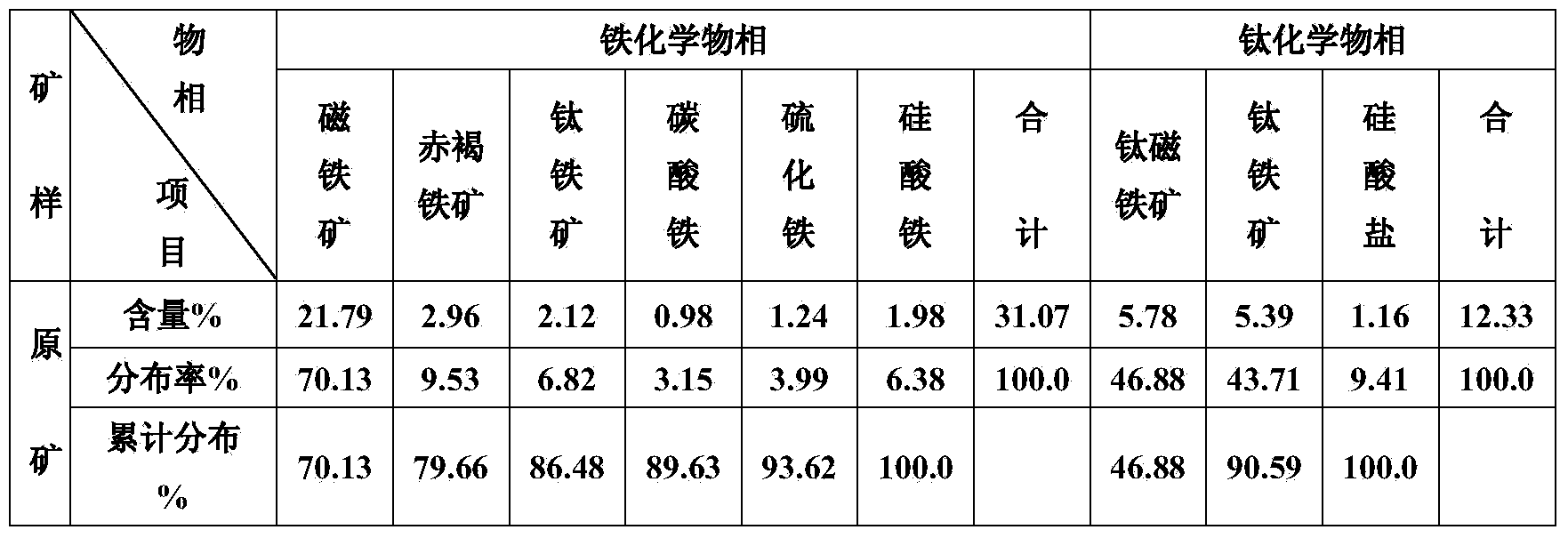

[0030] The TFe content is 53.1%, TiO 2 content of 11.2%, SiO 2 The content is 3.45%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 4.13% and a S content of 0.65% is placed in a NaOH alkali solution with a mass concentration of 20%, and is subjected to alkali leaching reaction at a temperature of 280° C. for 4 hours, and the reactant is filtered to obtain a filtrate and Alkali leaching filter cake A, NaOH consumption 81kg / t is fed to ore, and described filtrate is fed into recovery treatment system, and its chemical reaction formula is:

[0031]

[0032] 2) Desliming

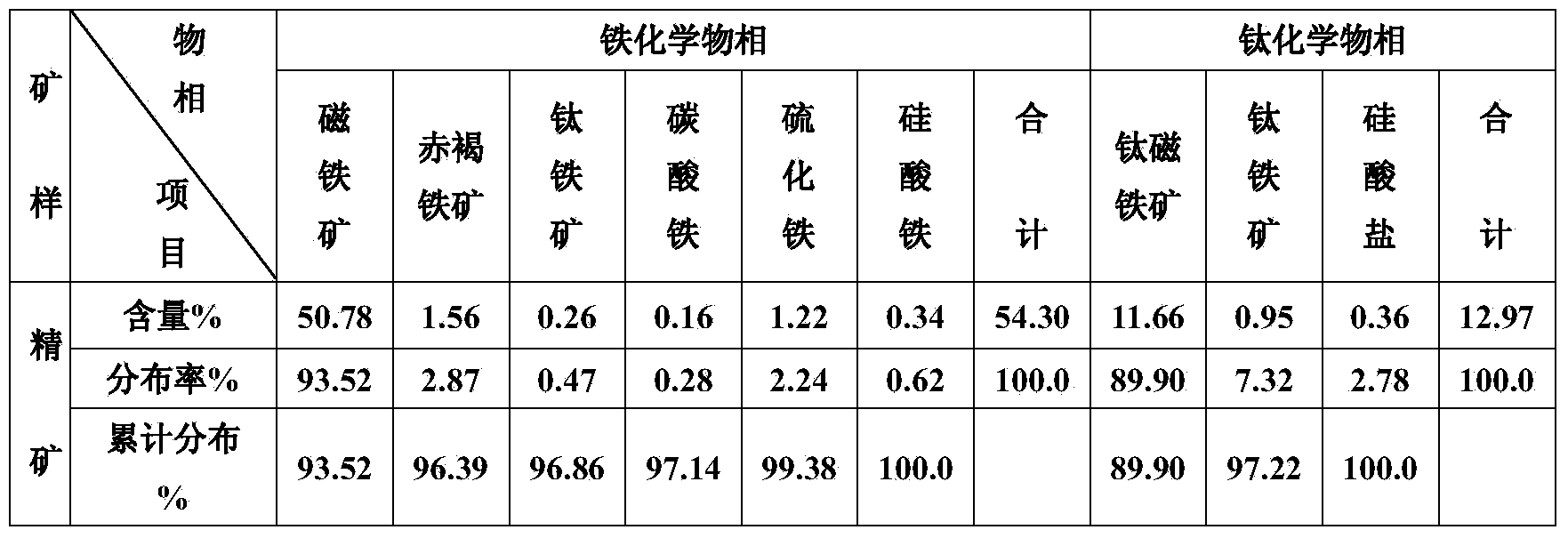

[0033] Add water to the alkali leaching filter cake A in step 1) to prepare a mass concentration of 24% ore slurry and feed it into a ∮ 3.0 m desliming hopper for desliming operation to obtain grit B and overflow C; the grit B It is the final iron concentrate (SiO 2 The content is 1.50%, Al 2 o 3 content is 1.65%, S content is 0.02%), the overflow C ...

Embodiment 2

[0035] 1) Alkaline leaching

[0036] The TFe content is 52.6%, TiO 2 content of 12.4%, SiO 2 The content is 3.62%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 5.55% and a S content of 0.78% is placed in a NaOH alkali solution with a mass concentration of 10%, and is subjected to alkali leaching reaction at a temperature of 370° C. for 5 hours, and the reactant is filtered to obtain the filtrate and Alkali leaching filter cake A, NaOH consumption 95kg / t feeds ore, and described filtrate feeds recovery processing system, and its chemical reaction formula is the same as embodiment 1.

[0037] 2) Desliming

[0038] Add water to the alkali leaching filter cake A in step 1) to prepare a mass concentration of 23% ore slurry and feed it into a ∮5.0m desliming hopper for desliming operation to obtain grit B and overflow C; the grit B It is the final iron concentrate (SiO 2 The content is 0.53%, Al 2 o 3 content is 1.24%, S content is 0.02%), the overf...

Embodiment 3

[0040] 1) Alkaline leaching

[0041] The TFe content is 53.2%, TiO 2 content of 12.7%, SiO 2 The content is 4.18%, Al 2 o 3 The vanadium-titanium magnetite concentrate with a content of 5.52% and a S content of 0.72% is placed in a NaOH alkali solution with a mass concentration of 35%, and is subjected to alkali leaching reaction at a temperature of 280° C. for 3 hours, and the reactant is filtered to obtain the filtrate and Alkali leaching filter cake A, NaOH consumption 86kg / t feeds ore, and described filtrate feeds recovery processing system, and its chemical reaction formula is the same as embodiment 1.

[0042] 2) Desliming

[0043] Add water to the alkali leaching filter cake A in step 1) to prepare a mass concentration of 25% ore slurry and feed it into a desliming hopper of ∮ 5.0 meters for desliming operation to obtain grit B and overflow C; the grit B It is the final iron concentrate with TFe content of 62.5% (SiO 2 The content is 0.66%, Al 2 o 3 content is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com