Two-stage type blowing breeze method and apparatus for blast furnace

An injection device, two-stage technology, used in blast furnaces, combustion methods, blast furnace details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

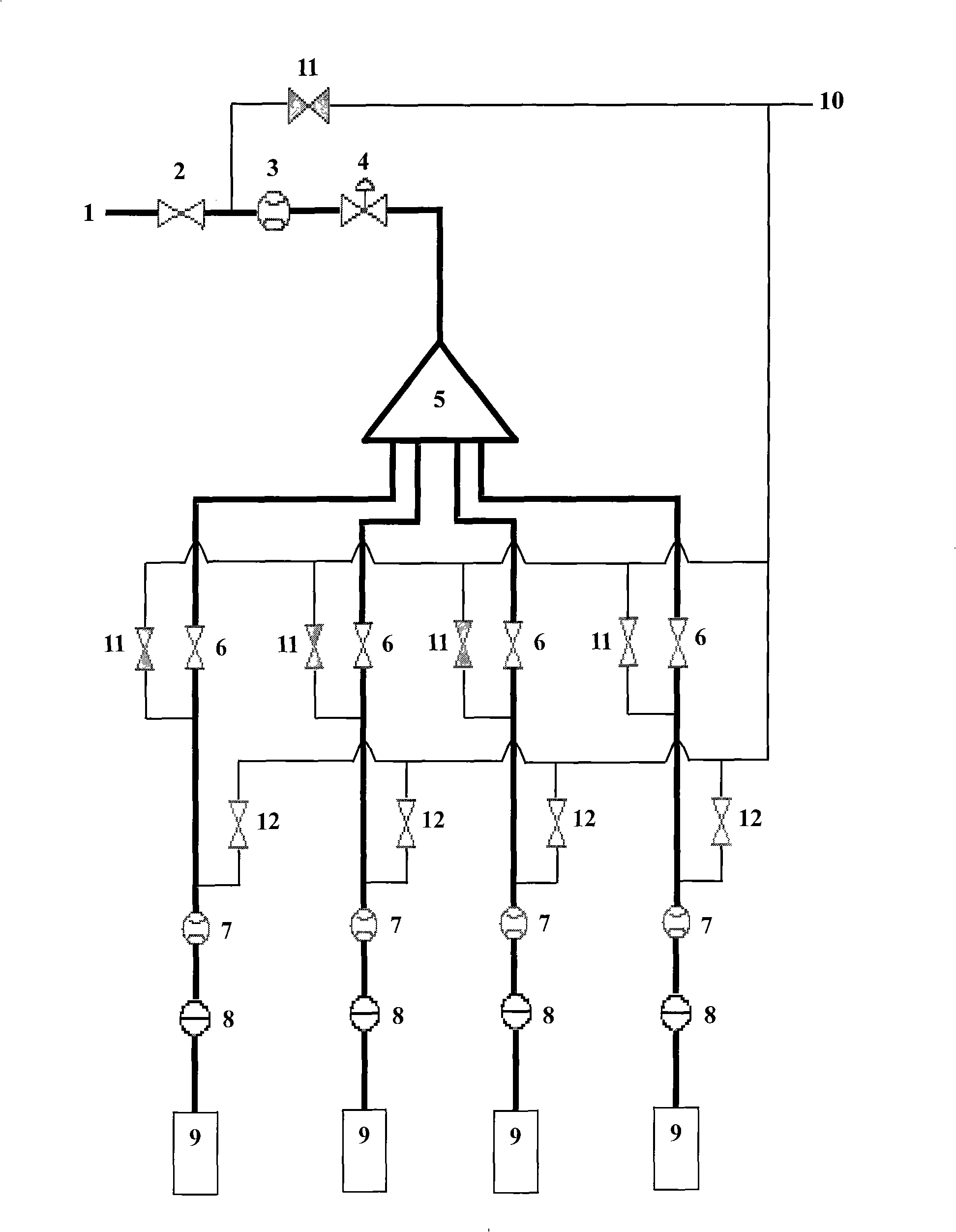

[0030] The volume of a blast furnace in a steel plant is 1800m 3 , In the early stage of implementing the two-stage injection, due to the unreasonable injection equipment and improper control of related parameters, gun blocking accidents occurred frequently (sometimes up to 8 times / day), and the desired effect was not received. Adopt the technology of this invention, its blowing equipment and attached figure 1 The device shown is the same, and there are four spray guns, which are symmetrically distributed on the same circle along the section of the furnace body at the lower part of the blast furnace shaft and above the reflow zone. And properly controlled the operating parameters of the second injection system, among which:

[0031] 1. The injection volume of a single gun is 350-650kg / h, with an average of 402kg / h;

[0032] 2. Control the solid-gas ratio to ≤20kg / kg through secondary air supply;

[0033] 3. Control the injection pressure P 风 +50kPa~P 风 +150kPa, the averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com