Method for improving utilization efficiency of solid fuel and application of solid fuel in production process of sintered ore

A solid fuel and production process technology, applied in the field of metallurgical sintering, can solve problems such as affecting the long-term stability of furnace conditions, wasting pig iron costs for sintering energy, and reducing the average particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

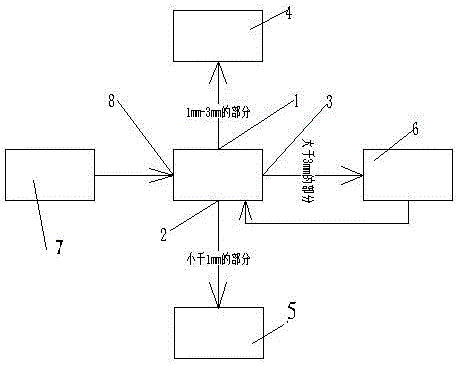

[0018] An air separator is added before the four-roller crusher 6 in the sintering solid fuel crushing chamber. First, the solid fuel in the solid fuel tank 7 is sent to the inlet 8 of the winnowing machine, and the solid fuel (coke powder or anthracite powder) smaller than 1mm is collected and sent to the blast furnace injection tank 5 as injection coal; 1mm~3mm Part of the solid fuel is directly transported to the batching chamber silo 4, and the part larger than 3mm is sent to the four-roller crusher 6 for crushing processing. After the solid fuel is crushed by the four-roller, it is returned to the winnowing machine for particle size classification, and the cycle goes on like this to ensure The particle size of the solid fuel is controlled within the appropriate range of 1mm~3mm.

[0019] The application of the prepared solid fuel in the production process of sintered ore:

[0020] (1) Mix iron ore powder such as hematite, limonite and magnetite in the pre-mixing room of ...

Embodiment 2

[0024] An air separator is added before the four-roller crusher 6 in the sintering solid fuel crushing chamber. First, the solid fuel in the solid fuel trough is sent to the inlet 8 of the winnowing machine, and the solid fuel (coke powder or anthracite powder) smaller than 1mm is collected and sent to the blast furnace injection tank 5 as injection coal; 1mm~3mm Part of the solid fuel is directly transported to the silo 4 of the batching room, while the part larger than 3mm is sent to the four-roll crusher 6 for crushing processing. After the solid fuel is crushed by the four rolls, it returns to the wind separator for particle size classification. The particle size of the fuel is controlled within the appropriate range of 1mm~3mm.

[0025] The application of the prepared solid fuel in the production process of sintered ore:

[0026] (1) Mix iron ore powder such as hematite, limonite and magnetite in the pre-mixing room of the raw material yard according to 60%: 25%: 15% to ...

Embodiment 3

[0030] An air separator is added before the four-roller crusher 6 in the sintering solid fuel crushing chamber. First, the solid fuel in the solid fuel trough is sent to the inlet 8 of the winnowing machine, and the solid fuel (coke powder or anthracite powder) smaller than 1mm is collected and sent to the blast furnace injection tank 5 as injection coal; 1mm~3mm Part of the solid fuel is directly transported to the silo 4 of the batching room, while the part larger than 3mm is sent to the four-roll crusher 6 for crushing processing. After the solid fuel is crushed by the four rolls, it returns to the wind separator for particle size classification. The particle size of the fuel is controlled within the appropriate range of 1mm~3mm.

[0031] The application of the prepared solid fuel in the production process of sintered ore:

[0032] (1) Mix iron ore powder such as hematite, limonite and magnetite in the pre-mixing room of the raw material yard according to 70%: 20%: 10% to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com