Modeling method and application of heat transfer and heat storage simulation model of hot blast stove

A technology of simulation model and modeling method, applied in the modeling field of heat transfer simulation model, which can solve the problems of low output of blast furnace, high energy consumption, lack of research on heat transfer and heat storage mechanism of hot blast furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described below in conjunction with the accompanying drawings.

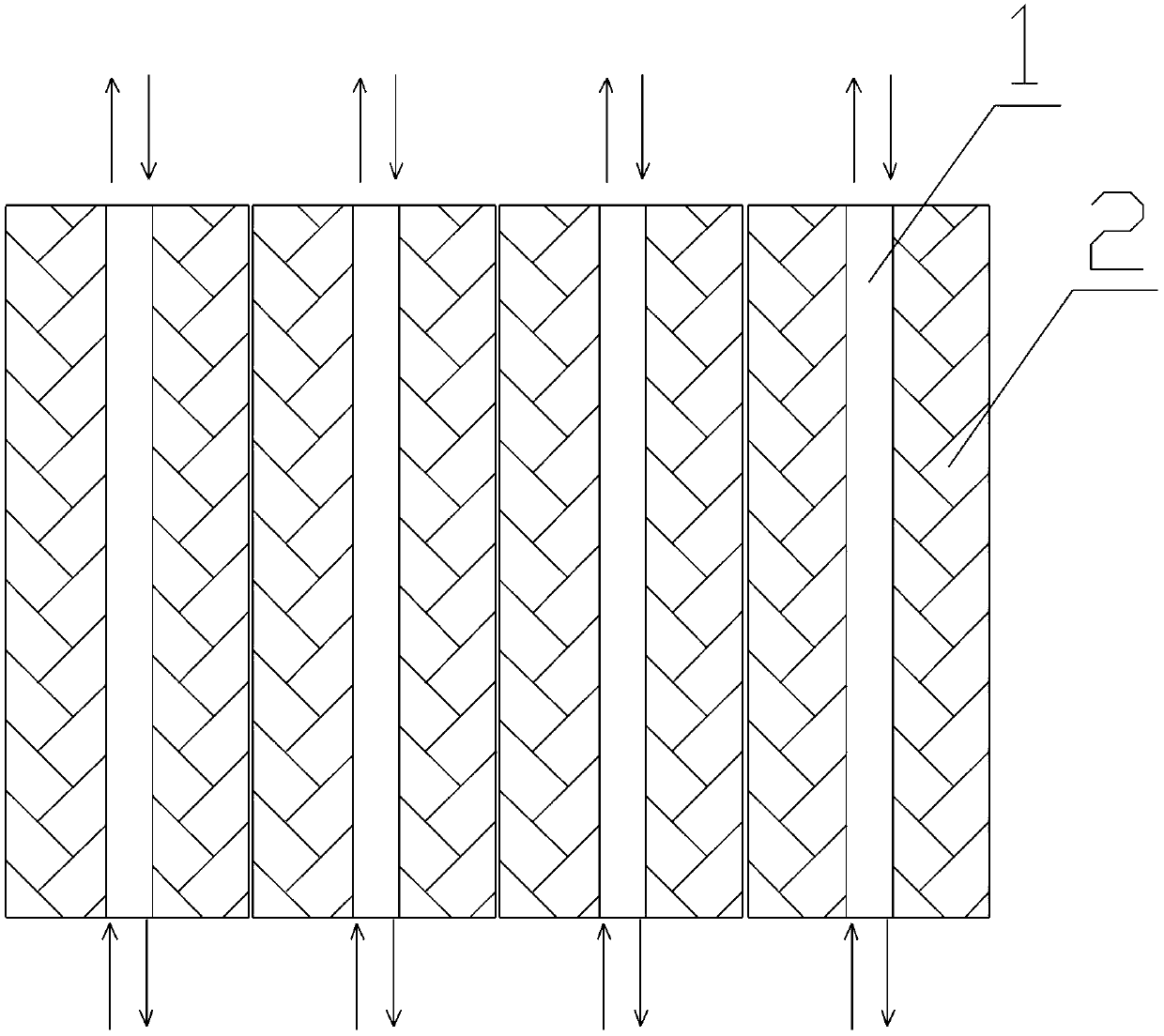

[0100] Since the regenerator in the regenerator of the hot blast stove is composed of many parallel arrangements of radial through holes, a schematic diagram is drawn according to the actual structure, as shown in figure 1 shown. Due to the complexity of the actual structure, only four control bodies are drawn here to represent its simplified structure. Since the regenerator is composed of many identical grid holes 1 arranged in parallel, it can be assumed that the flow velocity and temperature distribution of the gas flowing into each small hole are the same when performing numerical simulation calculations, then their flow and heat transfer process can be considered to be completely consistent.

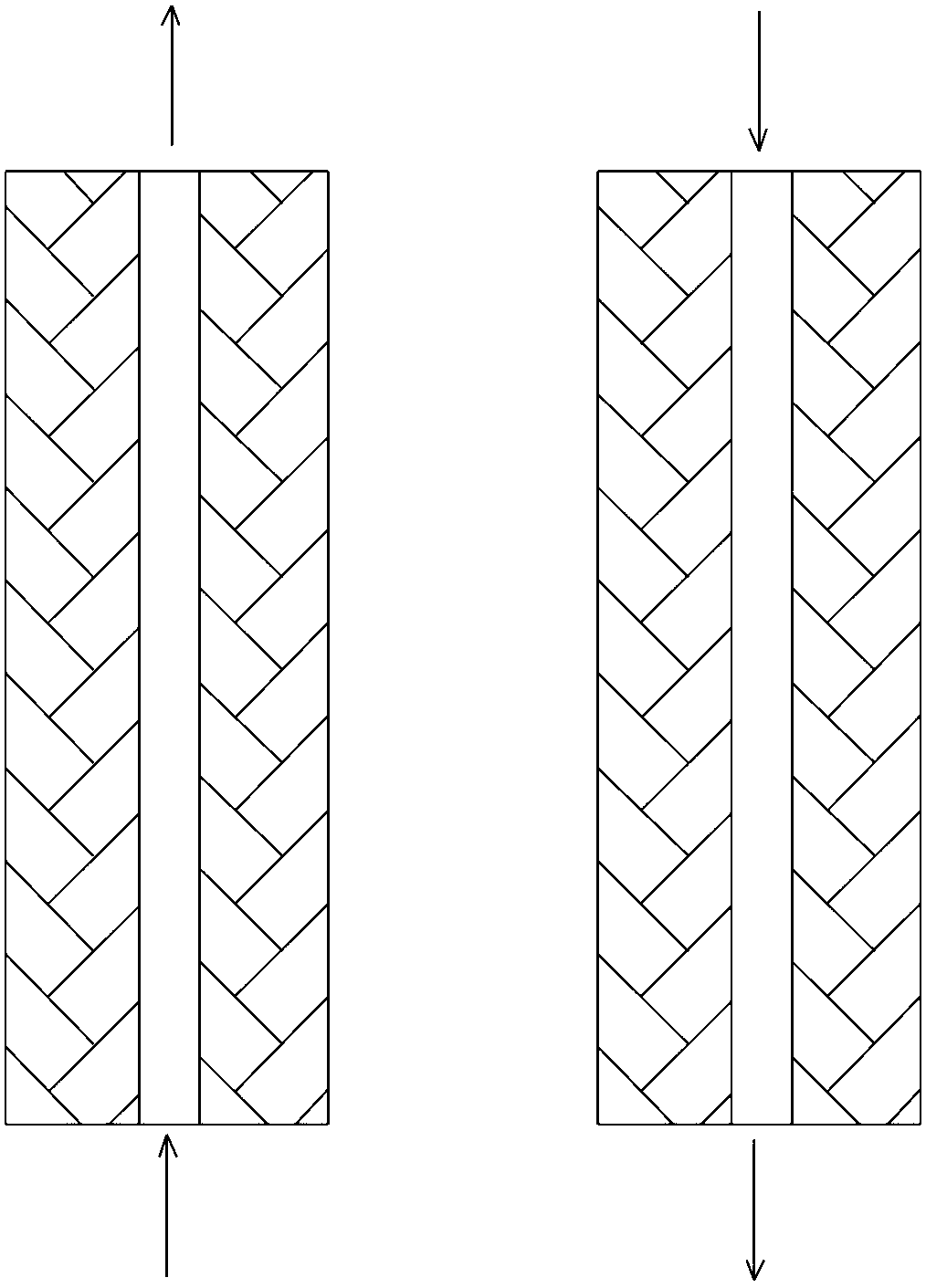

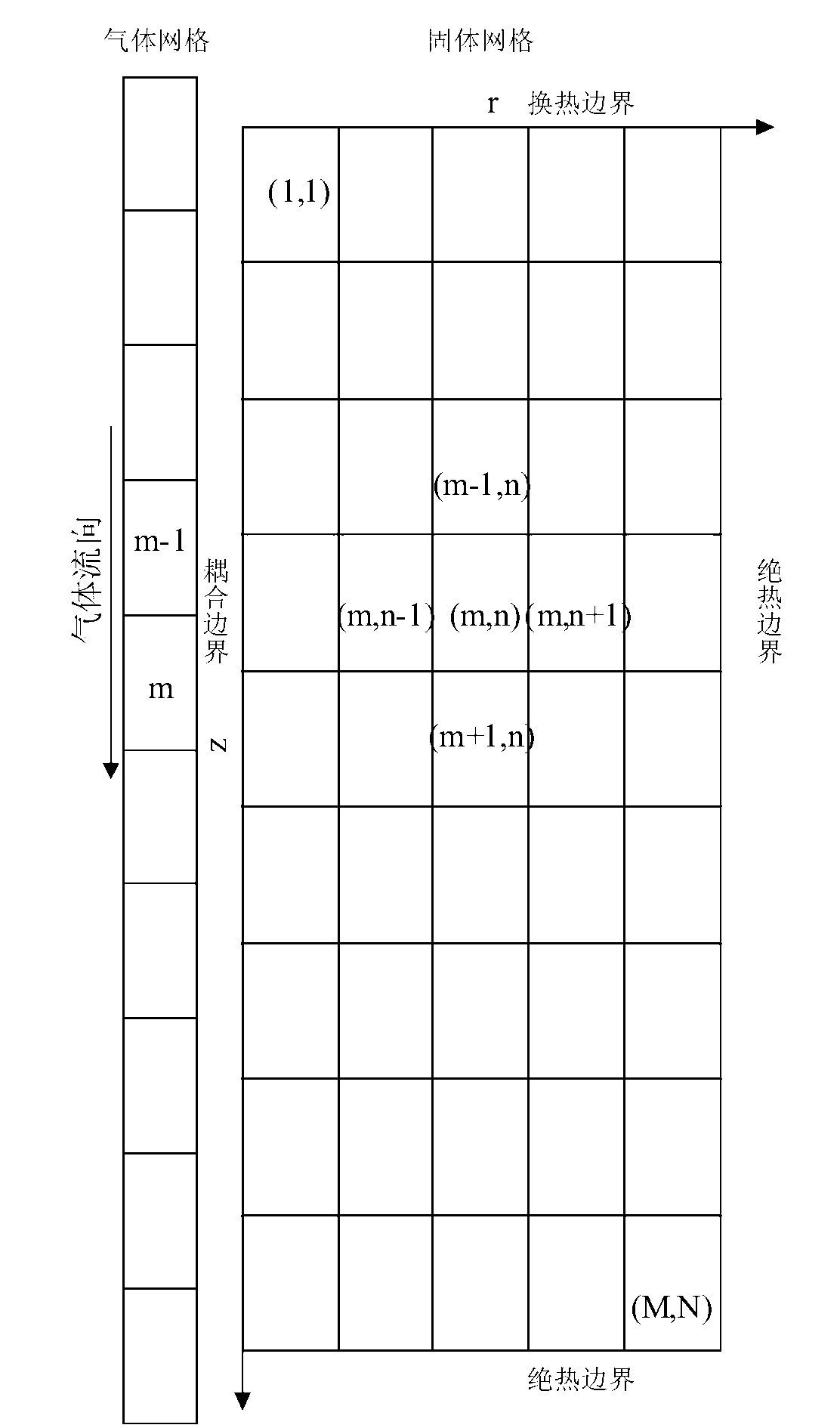

[0101] This paper takes a grid hole and the heat storage body controlled by it as an example to carry out the calculation. The schematic diagram of its structure is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com