Replacement method for cooling water pipe of cooling wall of blast furnace

A technology of cooling water pipes and staves, which is applied in the direction of cooling devices, etc., can solve the problems of the cooling wall losing its cooling function, the increase of heat flow intensity of cooling water pipes, and the reduction of cooling intensity, so as to avoid the problem of coke ratio increase and the replacement method is simple and easy , Guarantee the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

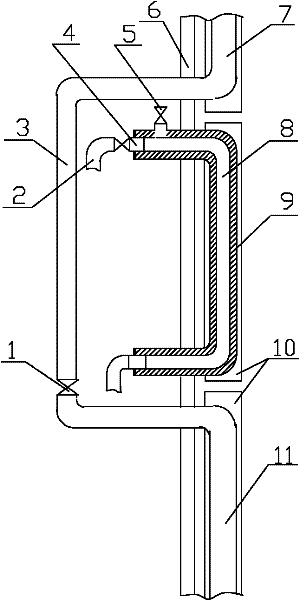

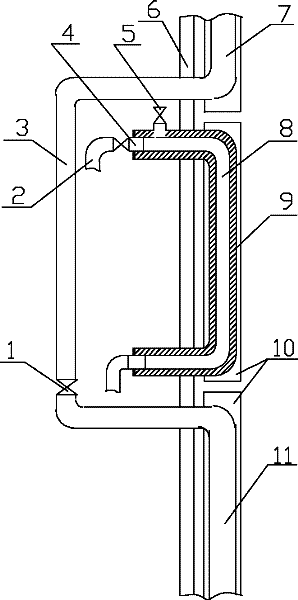

[0027] The accompanying drawing is a schematic diagram of the replacement connection of the cooling water pipe of the present invention. It can be seen from the drawings that a plurality of staves 10 are arranged on the inner wall of the blast furnace skin 6 , and a plurality of cooling water pipes are arranged in each stave 10 . In the present invention, the damaged cooling water pipe is first disconnected from the rear cooling water pipe 7 and the front cooling water pipe 11, and then the disconnected rear cooling water pipe 7 and the front cooling water pipe 11 are directly connected through a section of external cooling water pipe 3 , the incoming water in the front part cooling water pipe 11 crosses the damaged cooling water pipe and directly enters the rear part cooling water pipe 7, and the external cooling water pipe 3 is also provided with a ball valve 1. On the other hand, the present invention penetrates a metal hose 8 in the damaged cooling water pipe, and the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com