Blast furnace burden and method for improving comprehensive feeding grade of vanadium titano-magnetite blast furnace

A technology of vanadium-titanium magnetite and furnace grade, which is applied in the field of blast furnace charge, can solve the problems of high pig iron cost, high profit, and low output, and achieve the effects of increasing blast furnace output, improving furnace grade, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

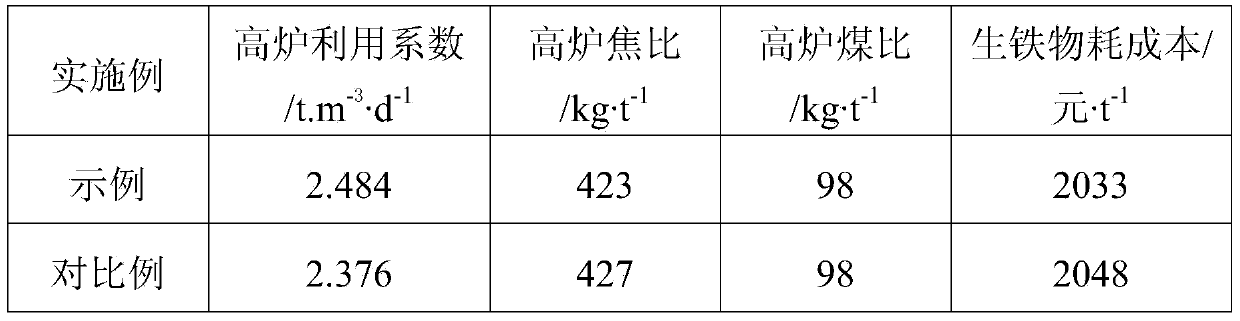

Examples

example 1

[0037] In this embodiment, the composition (mass percentage) of the blast furnace charge for improving the comprehensive grade of vanadium-titanium-magnetite blast furnace into the blast furnace is:

[0038] Vanadium-titanium sinter: 82%; vanadium-titanium pellets: 12.5%; acid lump ore: 2.5%; high-grade lump ore: 3%.

[0039] Put the above-mentioned blast furnace charge into the blast furnace for smelting, wherein, the composition of the blast furnace slag and the grade of the blast furnace entering the furnace are shown in Table 1.

example 2

[0041] In this embodiment, the composition (mass percentage) of the blast furnace charge for improving the comprehensive grade of vanadium-titanium-magnetite blast furnace into the blast furnace is:

[0042] Vanadium-titanium sinter: 77.5%; vanadium-titanium pellets: 15.5%; acid lump ore: 1%; high-grade lump ore: 6%.

[0043] Put the above-mentioned blast furnace charge into the blast furnace for smelting, wherein, the composition of the blast furnace slag and the grade of the blast furnace entering the furnace are shown in Table 1.

example 3

[0045] In this embodiment, the composition (mass percentage) of the blast furnace charge for improving the comprehensive grade of vanadium-titanium-magnetite blast furnace into the blast furnace is:

[0046] Vanadium-titanium sinter: 76%; vanadium-titanium pellets: 14%; acid lump ore: 0%; high-grade lump ore: 10%.

[0047] Put the above-mentioned blast furnace charge into the blast furnace for smelting, wherein, the composition of the blast furnace slag and the grade of the blast furnace entering the furnace are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com