Oxygen blast furnace iron-making method based on cold-bonded carbonic pellet

A blast furnace ironmaking and carbon pelletizing technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of high energy consumption, high pollution, high cost, etc., to improve metallization rate, reduce environmental pollution, and meet environmental protection requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

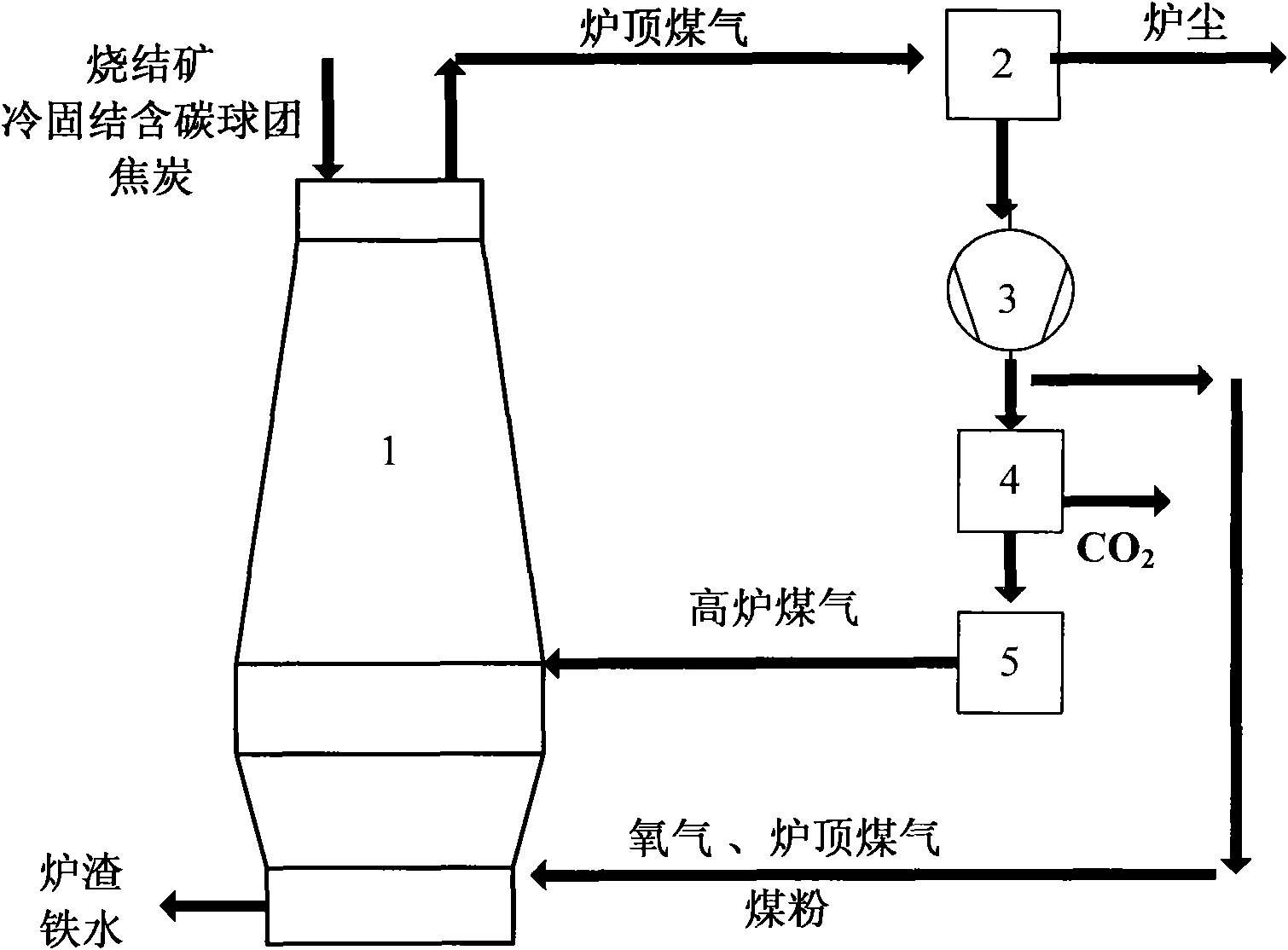

Image

Examples

Embodiment 1

[0027] According to theoretical calculations, the blast furnace uses 70% cold-solidified carbon-containing pellets with a carbon content of 10% as the raw material for the furnace, and 100% oxygen is blown in from the tuyere. The production technical indicators are as follows:

[0028] Oxygen consumption: 350Nm 3 / tHM

[0029] Coke ratio: 250kg / tHM

[0030] Coal for injection: 250kg / tHM

[0031] Coal powder used for cold consolidation carbonaceous pellets: 145kg / tHM

[0032] Theoretical combustion temperature: 2155°C

[0033] Furnace top gas volume: 1550Nm 3 / tHM

[0034] Top gas composition: H 2 : 5.75%, CO: 48.65%, CO 2 : 36.65%, N 2 : 0.33%

Embodiment 2

[0036] According to theoretical calculations, 70% of cold-solidified carbon-containing pellets with a carbon content of 15% are used as raw materials for the blast furnace, and 100% of oxygen is blown in from the tuyere. The production technical indicators are as follows:

[0037] Oxygen consumption: 350Nm 3 / tHM

[0038] Coke ratio: 225kg / tHM

[0039] Coal for injection: 237kg / tHM

[0040] Coal for cold consolidation carbonaceous pellets: 225kg / tHM

[0041] Theoretical combustion temperature: 2185°C

[0042] Furnace top gas volume: 1600Nm 3 / tHM

[0043] Top gas composition: H 2 : 5.71%, CO: 45.20%, CO 2 : 38.95%, N 2 : 0.33%

Embodiment 3

[0045] According to theoretical calculations, 70% of cold-solidified carbon-containing pellets with a carbon content of 20% are used as raw materials for the blast furnace, and 100% of oxygen is blown in from the tuyere. The production technical indicators are as follows:

[0046] Oxygen consumption: 350Nm 3 / tHM

[0047] Coke ratio: 220kg / tHM

[0048] Coal for injection: 230kg / tHM

[0049] Coal for cold consolidation carbonaceous pellets: 295kg / tHM

[0050]Theoretical combustion temperature: 2220°C

[0051] Furnace top gas volume: 1600Nm 3 / tHM

[0052] Top gas composition: H 2 : 5.35%, CO: 47.28%, CO 2 : 36.75%, N 2 : 0.35%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com