Method by adopting carbon dioxide as transmission medium for blast furnace coal injection

A technology of carbon dioxide and blast furnace coal injection, applied in tuyere and other directions, can solve problems such as limiting blast furnace ironmaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

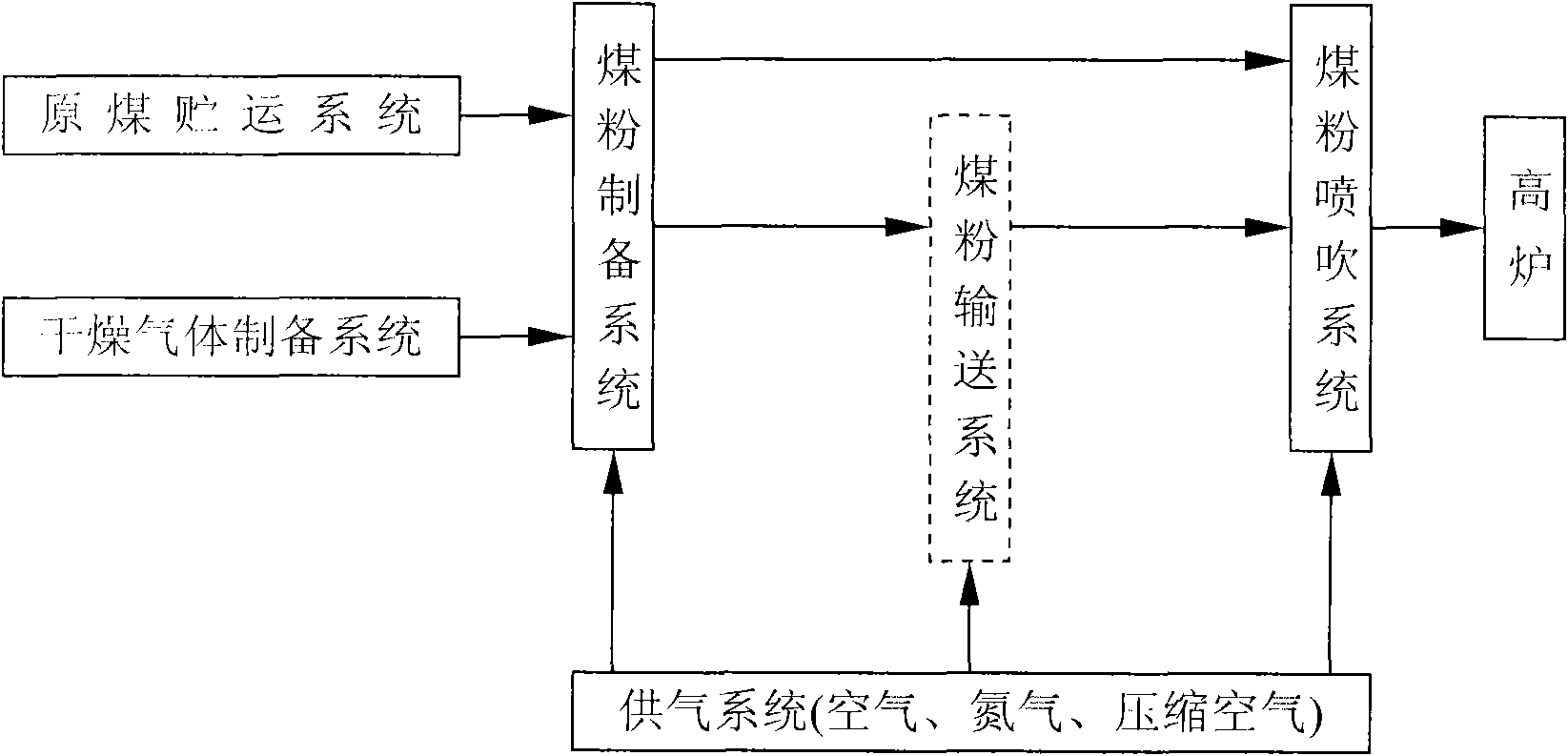

[0019] A method for blast furnace coal injection using carbon dioxide as a transmission medium, which is carried out in sequence as follows: a. storage and transportation of raw coal, b. preparation of dry gas, c. preparation of coal powder, d. transportation of coal powder and e. injection of coal powder ,Specific steps are as follows::

[0020] a. When storing and transporting raw coal, choose anthracite or bituminous coal with an ash content less than 15%, a sulfur content less than 1%, and a moisture content less than 2%, and control the storage and transport temperature at 70°C to 80°C;

[0021] b. When preparing dry gas, choose blast furnace hot blast stove flue gas or mixed dry gas. The mixed dry gas consists of hot blast stove flue gas with a volume of 90% to 95% and a temperature of 150°C to 300°C and a volume of 5 % to 10% and mixed with high-temperature flue gas produced by a combustion furnace with a temperature of 9000 ° C to 1000 ° C, and the obtained dry gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com