Method for preparing vehicle urea solution

A technology of urea and urea aqueous solution for vehicles is applied in the field of chemical technology, which can solve the problems of high steam consumption and low urea purity, and achieve the effect of reducing production links and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

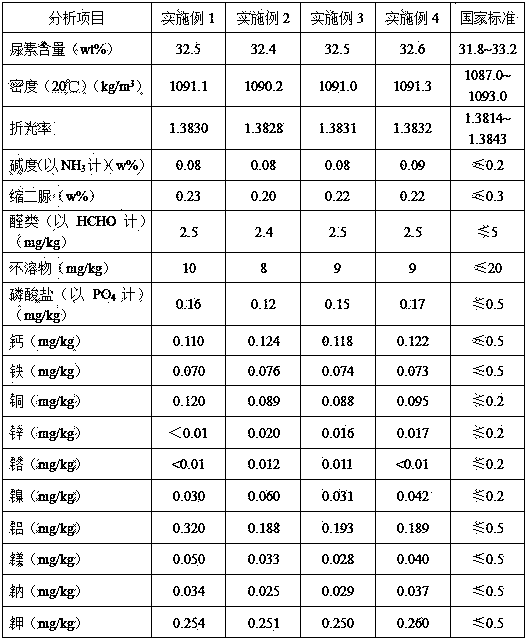

Examples

Embodiment 1

[0016] (1) Lift the industrial desalted water into the reverse osmosis device with a high-pressure pump, the water output from the reverse osmosis device enters the intermediate water tank, the intermediate water tank passes through a microporous filter to the pure water tank, and the effluent from the pure water tank is sterilized after being treated by an EDI electrodeionization device High-purity water, the conductivity of high-purity water is less than 0.06μs / cm, and the resistivity is 16.8MΩ.cm25℃;

[0017] (2) Remove ammonia and CO by flash evaporation during urea production 2 The final temperature is 90.6°C, and the high-temperature urea solution with a concentration of 74.9% is fully mixed with the high-purity water prepared in step (1) to prepare an aqueous urea solution with a temperature of 69.2°C and a concentration of 48.6wt%;

[0018] (3) The aqueous urea solution in step (2) was cooled to 25°C, filtered to obtain crystalline urea, and the crystalline urea was mi...

Embodiment 2

[0021] (1) Lift the industrial desalted water into the reverse osmosis device with a high-pressure pump, the water output from the reverse osmosis device enters the intermediate water tank, the intermediate water tank passes through a microporous filter to the pure water tank, and the effluent from the pure water tank is sterilized after being treated by an EDI electrodeionization device High-purity water, the conductivity of high-purity water is less than 0.06μs / cm, and the resistivity is 17.7MΩ.cm25℃;

[0022] (2) Remove ammonia and CO by flash evaporation during urea production 2 The final temperature is 85.0°C, and the high-temperature urea solution with a concentration of 84% is fully mixed with the high-purity water prepared in step (1) to prepare an aqueous urea solution with a temperature of 71.8°C and a concentration of 53.6wt%;

[0023] (3) The aqueous urea solution in step (2) was cooled to 25°C, filtered to obtain crystallized urea, and the crystallized urea was mi...

Embodiment 3

[0026] (1) Lift the industrial desalted water into the reverse osmosis device with a high-pressure pump, the water output from the reverse osmosis device enters the intermediate water tank, the intermediate water tank passes through a microporous filter to the pure water tank, and the effluent from the pure water tank is sterilized after being treated by an EDI electrodeionization device High-purity water, the conductivity of high-purity water is less than 0.06μs / cm, and the resistivity is 18.0MΩ.cm25℃;

[0027] (2) Remove ammonia and CO by flash evaporation during urea production 2 The final temperature is 92.4°C, and the high-temperature urea solution with a concentration of 80.3% is fully mixed with the high-purity water prepared in step (1) to prepare an aqueous urea solution with a temperature of 70.3°C and a concentration of 50.7wt%;

[0028] (3) Cool the aqueous urea solution in step (2) to 20°C, filter to obtain crystalline urea, and mix the crystalline urea with high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com