Method for preparing magnetic 4A molecular sieve from coal gangue

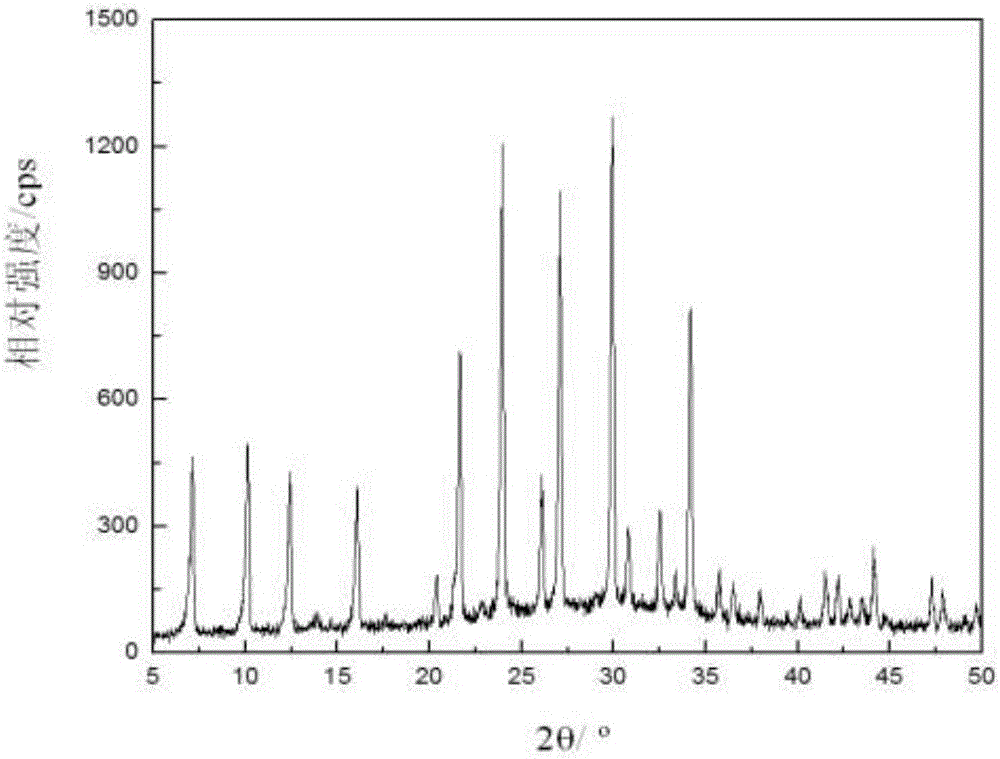

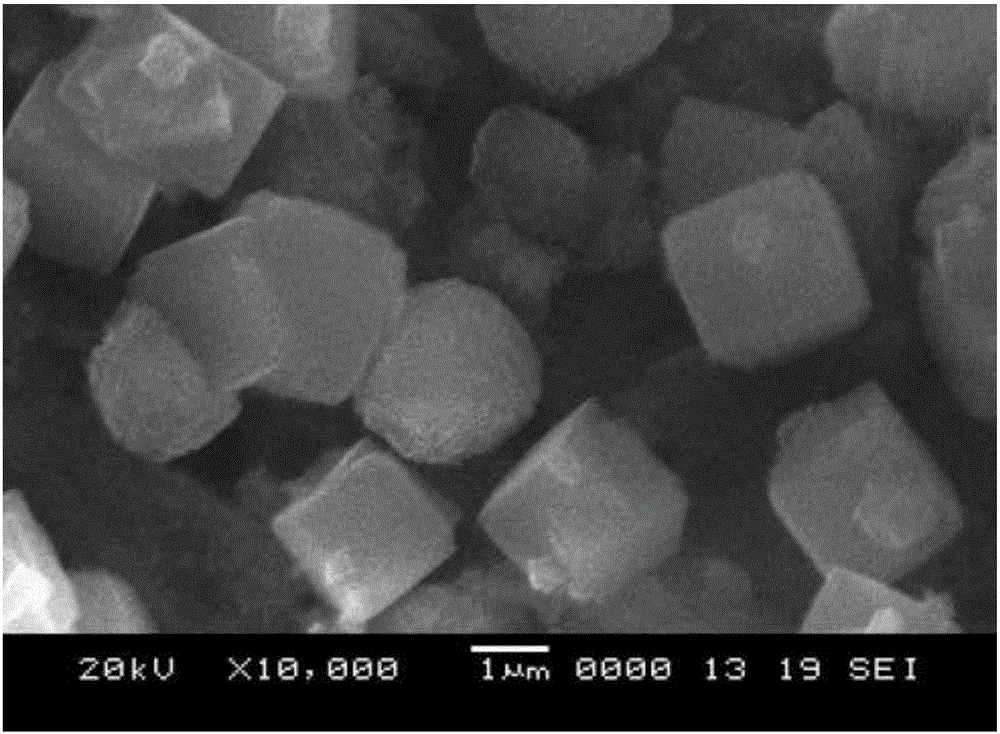

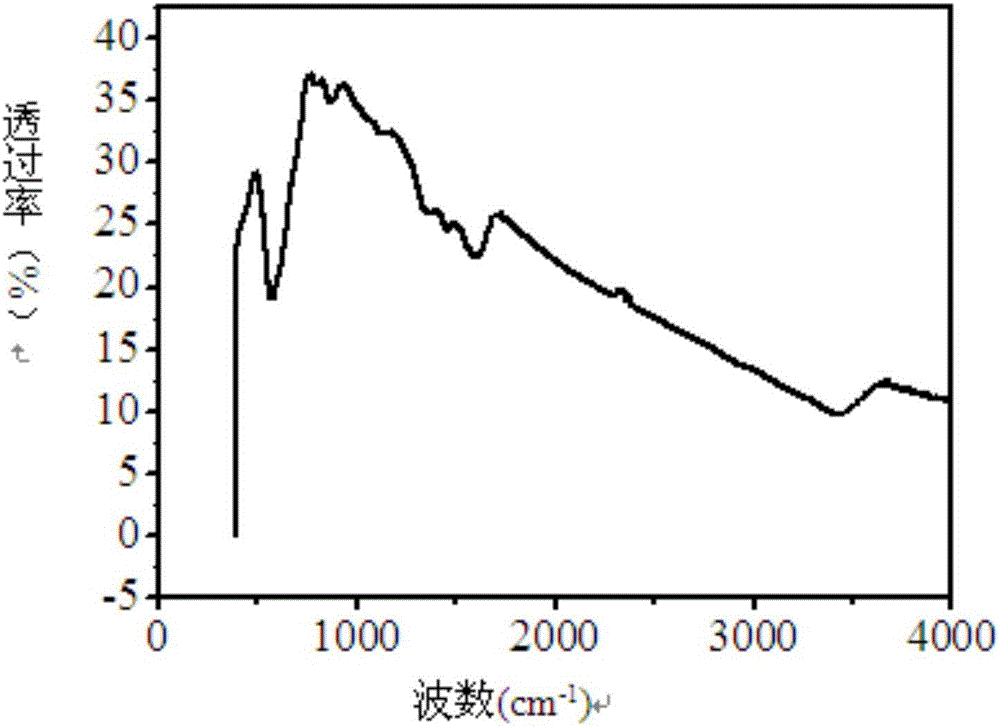

A technology of coal gangue and molecular sieve, which is applied in the field of 4A molecular sieve preparation, can solve the problem of high cost synthesis of molecular sieve, and achieve the effect of reducing preparation and application cost, good crystallinity and improving application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment utilizes coal gangue to prepare magnetic 4A molecular sieve and includes the following steps:

[0034] Step 1: Grind the coal gangue to 320 mesh and place it in an ash pan, then add ammonium chloride to the ash pan, roast it for 2.5 hours at a temperature of 850° C. and grind it to obtain a pretreated sample; the coal gangue is The mass ratio with ammonium chloride is 1.8:1;

[0035] Step 2, FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 O was added to distilled water, stirred at a stirring rate of 750 r / min under nitrogen protection, heated to 80 °C while stirring, and then added NH 3 ·H 2 After 0, continue to stir for 30min to obtain a solid-liquid mixture, after natural cooling, use a magnet to adsorb the magnetic substance in the solid-liquid mixture, then repeatedly wash the adsorbed magnetic substance, and dry it at a temperature of 70°C for 5.5h. get magnetic Fe 3 O 4 ; the FeCl 2 ·4H 2 O, FeCl 3 ·6H 2 O and NH 3 ·H 2 The amount of O added i...

Embodiment 2

[0046] The present embodiment utilizes coal gangue to prepare magnetic 4A molecular sieve and includes the following steps:

[0047] Step 1: Grind the coal gangue to 325 mesh and place it in an ash pan, then add ammonium chloride to the ash pan, roast it for 2 hours at a temperature of 860°C, and grind it to obtain a pretreated sample; The mass ratio of ammonium chloride is 2:1;

[0048] Step 2, FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 O was added to distilled water, stirred at a stirring rate of 1000 r / min under nitrogen protection, heated to 85 °C while stirring, and then added NH 3 ·H 2 After 0, continue to stir for 20min to obtain a solid-liquid mixture. After natural cooling, use a magnet to adsorb the magnetic substance in the solid-liquid mixture. After that, the adsorbed magnetic substance is repeatedly washed, and dried at a temperature of 75°C for 5h to obtain Magnetic Fe 3 O 4 ; the FeCl 2 ·4H 2 O, FeCl 3 ·6H 2 O, NH 3 ·H 2 The amount of O and distilled water a...

Embodiment 3

[0054] The present embodiment utilizes coal gangue to prepare magnetic 4A molecular sieve and includes the following steps:

[0055] Step 1: Grind the coal gangue to 300 mesh and place it in an ash pan, then add ammonium chloride to the ash pan, roast it for 3 hours at a temperature of 850°C, and grind it to obtain a pretreated sample; The mass ratio of ammonium chloride is 1.5:1;

[0056] Step 2, FeCl 2 ·4H 2 O and FeCl 3 ·6H 2 O was added to distilled water, stirred at a stirring rate of 800 r / min under nitrogen protection, heated to 75 °C while stirring, and then added NH 3 ·H 2 After 0, continue to stir for 40 min to obtain a solid-liquid mixture. After natural cooling, use a magnet to adsorb the magnetic substance in the solid-liquid mixture. After that, the adsorbed magnetic substance is repeatedly washed, and dried at a temperature of 65 ° C for 6 h to obtain Magnetic Fe 3 O 4 ; the FeCl 2 ·4H 2 O, FeCl 3 ·6H 2 O and NH 3 ·H 2 The amount of O added is: eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com