Method for preparing magnetic P-type molecular sieve by using coal gangue

A technology of molecular sieves and coal gangue, which is applied in the field of preparing magnetic P-type molecular sieves from coal gangue, can solve the problems of high cost synthesis of molecular sieves, solid-liquid separation of P-type molecular sieves, etc., so as to improve the reuse rate, reduce the cost of preparation and application, and reduce the The effect of crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

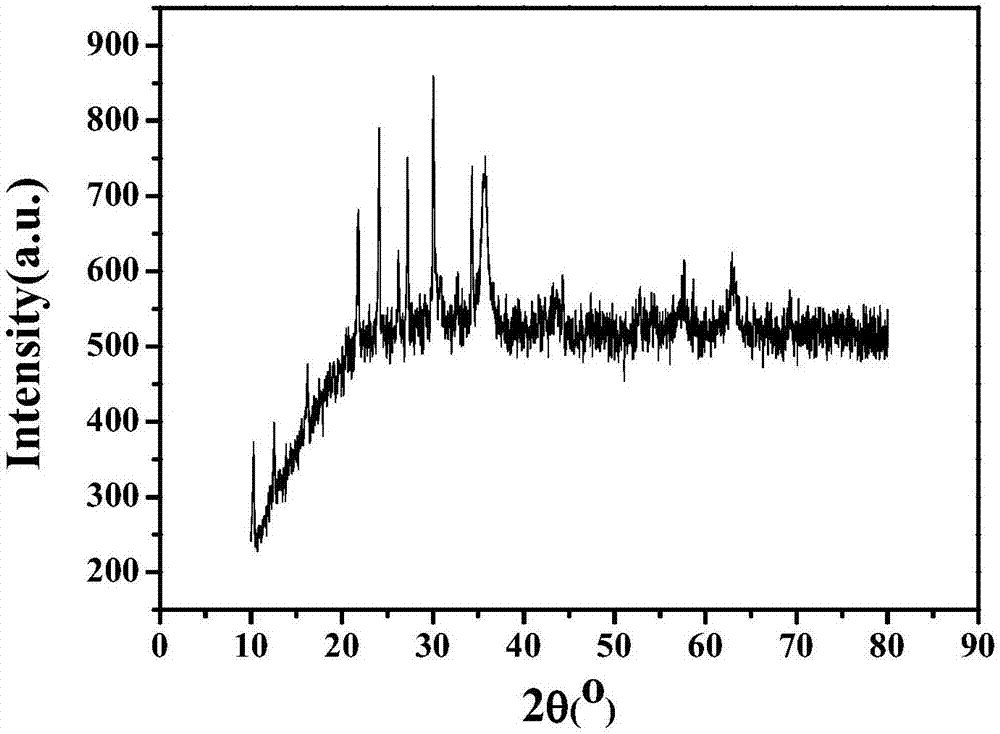

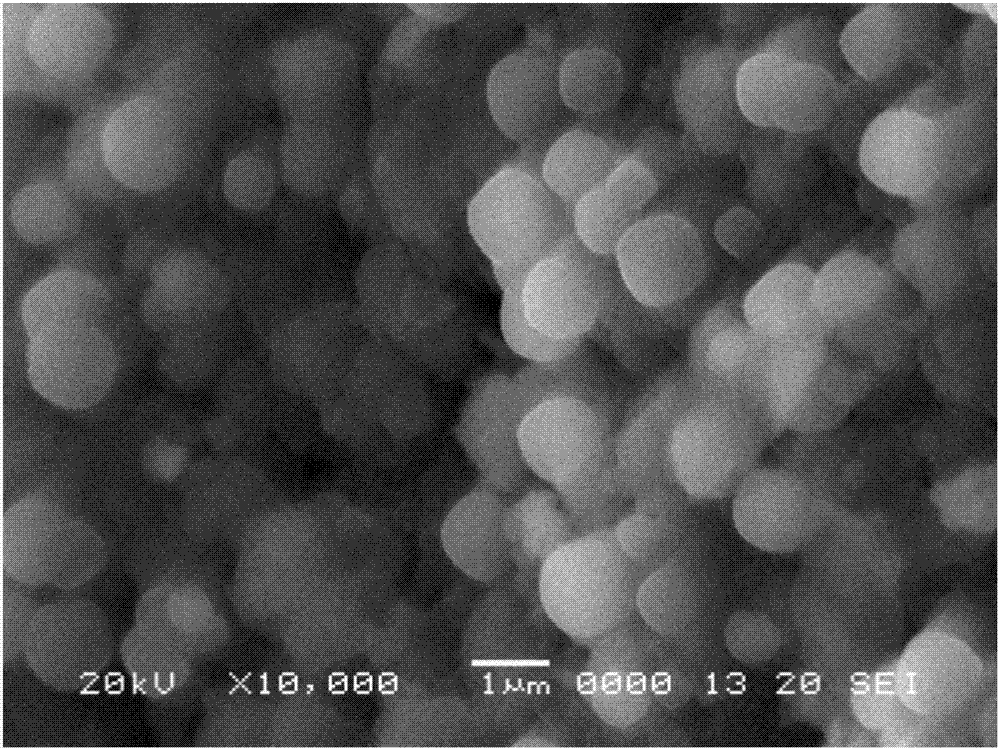

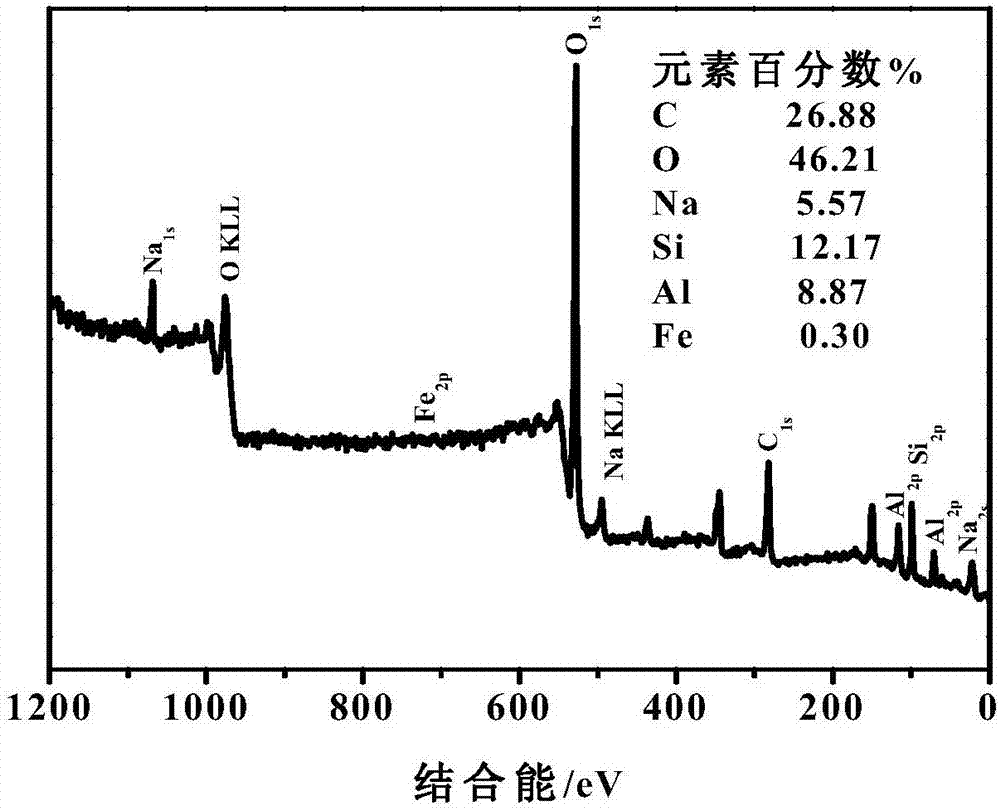

[0031] Utilize coal gangue to prepare the method for magnetic P-type molecular sieve in the present embodiment and comprise the following steps:

[0032] Step 1: Grind coal gangue to 315 mesh coal gangue powder and place it in an ash dish, then add sodium carbonate to the ash dish, roast for 2 hours at a temperature of 900° C. and then grind to obtain a pretreated sample; the sodium carbonate The mass ratio to coal gangue powder is 3:1;

[0033] Step 2. Oxidize the pretreated sample obtained in step 1 at a temperature of 350° C. for 2 hours, then add hydrochloric acid solution, soak for 2 hours at a temperature of 90° C., and filter to obtain a filter residue and a filtrate. The filtrate Contains Fe 3+ , which is composed of hydrochloric acid solution and Fe in gangue ash 2 o 3 Reaction and dissolution are obtained; the mass concentration of the hydrochloric acid solution is 15%, and the consumption of the hydrochloric acid solution is to add 5mL hydrochloric acid solution ...

Embodiment 2

[0046] Utilize coal gangue to prepare the method for magnetic P-type molecular sieve in the present embodiment and comprise the following steps:

[0047] Step 1: Grind coal gangue to 315 mesh coal gangue powder and place it in an ash dish, then add sodium carbonate to the ash dish, roast at a temperature of 890°C for 2.5 hours and then grind to obtain a pretreated sample; The mass ratio of sodium to gangue powder is 2.5:1;

[0048] Step 2. Oxidize the pretreated sample obtained in step 1 at a temperature of 375° C. for 1.8 hours, then add hydrochloric acid solution, soak for 2.5 hours at a temperature of 95° C., and filter to obtain a filter residue and a filtrate. The filtrate contains Fe 3+ , which is composed of hydrochloric acid solution and Fe in gangue ash 2 o 3 obtained by reaction and dissolution; the oxalic acid and the Fe in the filtrate 3+ The mol ratio is 5:1; The mass concentration of described hydrochloric acid solution is 15%, and the consumption of hydrochl...

Embodiment 3

[0054] Utilize coal gangue to prepare the method for magnetic P-type molecular sieve in the present embodiment and comprise the following steps:

[0055] Step 1: Grind the coal gangue to 300 mesh coal gangue powder and place it in the ash dish, then add sodium carbonate to the ash dish, roast for 3 hours at a temperature of 880° C. and then grind to obtain a pretreated sample; the sodium carbonate The mass ratio to coal gangue powder is 2:1;

[0056] Step 2. Oxidize the pretreated sample obtained in step 1 at a temperature of 400° C. for 1.5 hours, then add hydrochloric acid solution, soak for 3 hours at a temperature of 90° C., and filter to obtain a filter residue and a filtrate. The filtrate Contains Fe 3+ , which is composed of hydrochloric acid solution and Fe in gangue ash 2 o 3 obtained by reaction and dissolution; the oxalic acid and the Fe in the filtrate 3+ The mol ratio is 5:1; The mass concentration of described hydrochloric acid solution is 15%, and the consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com