Preparation method of 13X molecular sieve and 13X molecular sieve

A technology of molecular sieve and mass percentage, applied in octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of limited popularization and application, large energy consumption, low mass transfer efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

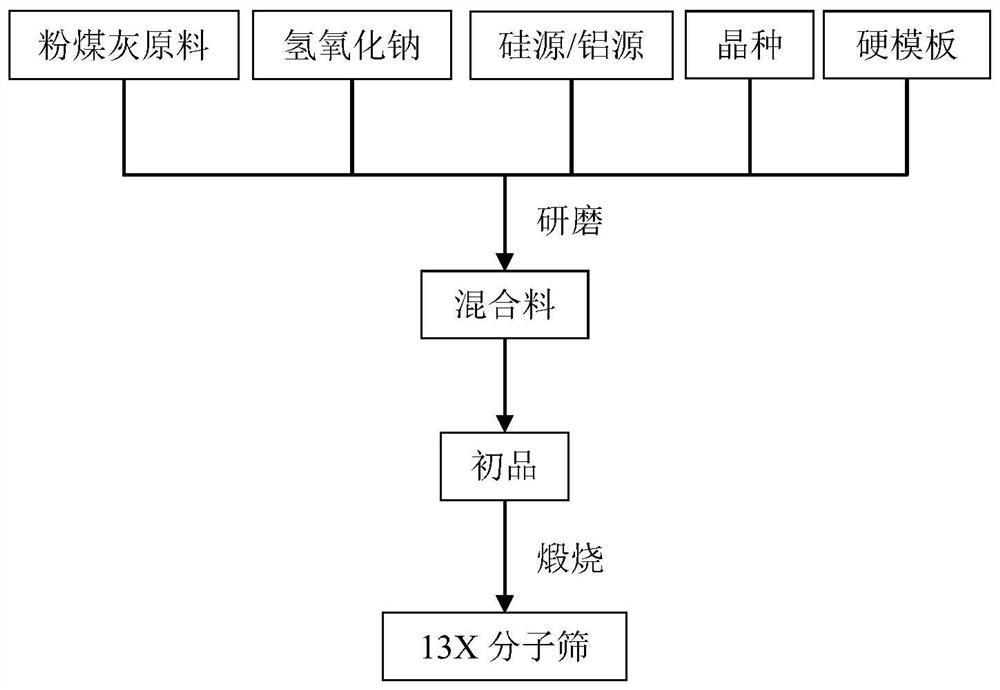

[0043] see figure 1 , The invention provides a preparation method of 13X molecular sieve. The preparation method comprises the following steps:

[0044] (1) Remove impurity iron, wash, filter and dry the fly ash of the circulating fluidized bed with a magnetic separator to obtain the fly ash raw material;

[0045] (2) this fly ash raw material is mixed with sodium hydroxide, silicon source, aluminum source, 13X molecular sieve crystal seed, hard formwork, obtain compound by grinding afterwards;

[0046] (3) crystallize the mixture in the range of 80-98° C. for 15-24 hours to obtain a crystallized product, and then cool the crystallized product to obtain the first product of 13X molecular sieve;

[0047] (4) Calcining the primary product at a temperature of 500-600°C for 4-8 hours to obtain a calcined product, after cooling the calcined product, washing and filtering, and then drying at a temperature of 50-70°C After 10-15 hours, 13X molecular sieves were obtained.

[0048]...

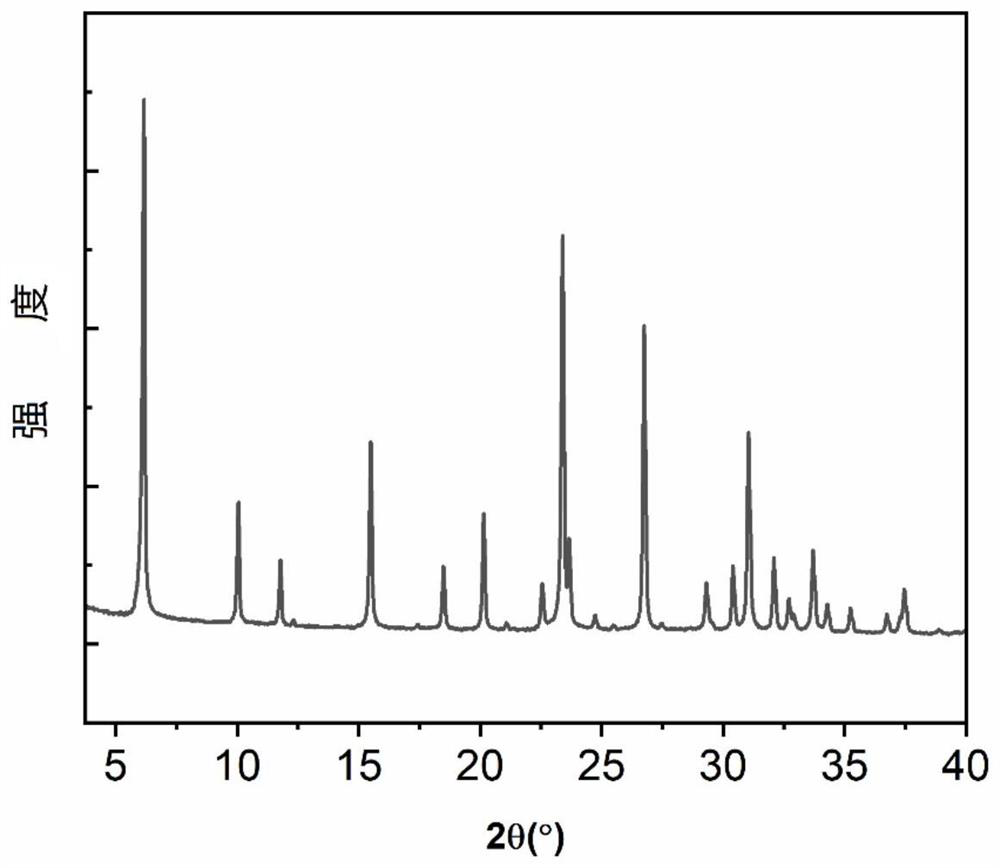

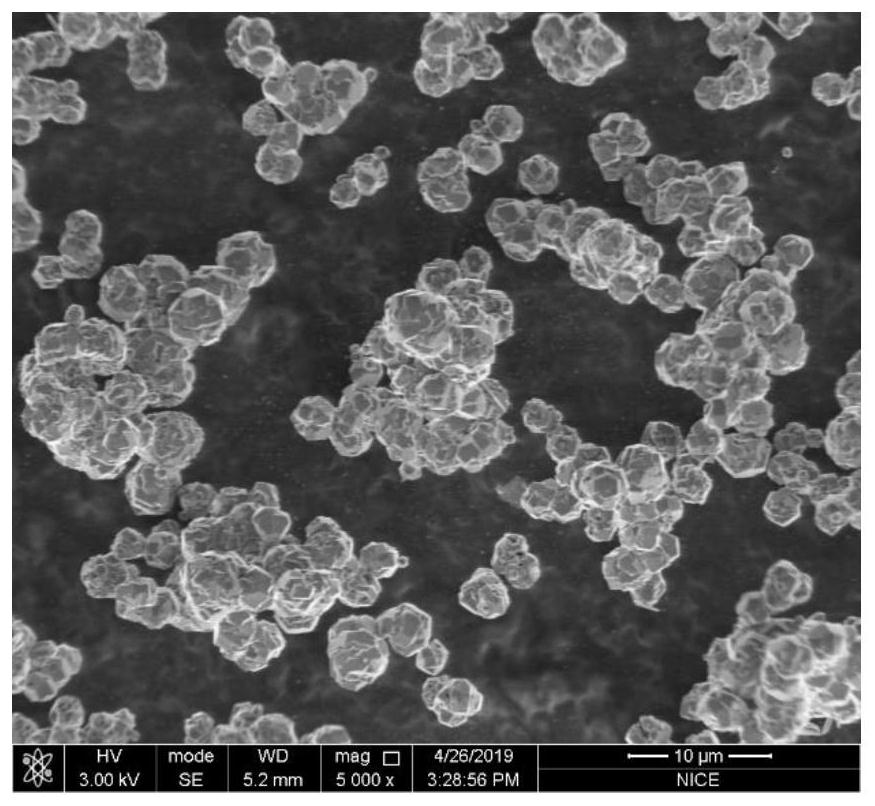

Embodiment 1

[0057] In this example, first, an appropriate amount of circulating fluidized bed fly ash containing a certain silicon-aluminum ratio is subjected to magnetic separation to remove iron, and then deionized water is added to wash and remove the floating matter in the fly ash, and the fly ash is filtered to remove soluble salt, and then dried in an oven at 110°C for 6 hours to obtain the raw material of fly ash. Then, mix and grind according to the ratio of 70% fly ash raw material, 10% sodium hydroxide, 7% sodium silicate, 2% aluminum hydroxide, 8% seed crystal and 3% hard template After uniformity, place it in a reaction kettle, crystallize in an oven at 95°C for 16 hours to obtain a crystallized product, and then cool the crystallized product to obtain a primary product. The primary product was calcined in a muffle furnace at 550°C for 6 hours. Finally, wash several times with deionized water, filter to remove the hard template, and dry in an oven at 60°C for 12 hours to obta...

Embodiment 2

[0060] In this example, firstly, an appropriate amount of circulating fluidized bed fly ash containing a certain silicon-aluminum ratio is subjected to magnetic separation to remove iron, then deionized water is added to wash to remove floating matter, and soluble salt is filtered to remove, and then heated in an oven at 110°C Dry for 6 hours to obtain the fly ash raw material. Then, mix and grind evenly according to the ratio of 78% of fly ash raw material, 10% of sodium hydroxide, 7% of sodium silicate, 2% of aluminum hydroxide and 3% of hard template, and then place it in the reactor , crystallized in an oven at 95°C for 16 hours, and cooled the crystallized product to obtain the primary product. The primary product was calcined in a muffle furnace at 550°C for 6 hours. Finally, wash with deionized water several times, filter, and dry in an oven at 60°C for 12 hours to obtain the final product microporous-mesoporous 13X molecular sieve.

[0061] Compared with Example 1, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com