Method for purifying and concentrating CO from calcium carbide furnace gas

A calcium carbide furnace gas and pre-purification technology, applied in the direction of carbon monoxide, carbide, calcium carbide, etc., can solve the problems of not meeting the purity requirements of CO gas, cyanide sewage treatment, etc., and achieve high reliability, high CO yield, and device running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

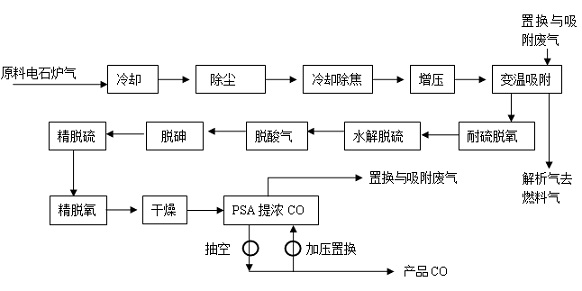

Method used

Image

Examples

Embodiment 1

[0041] Table 1 Composition of raw calcium carbide gas

[0042] Component CO H 2 CO 2 N 2 O 2 CH 4 tar ∑ V% 80 5.9 3.6 5.8 2.0 1.2 1.5

[0043] Table 2 Impurity components

[0044] Component dust moisture h 2 S Thiol COS CS 2 Thiophene NO x P 4 pH 3 H 3 HCN mg / Nm 3 1.5×10 5 8.7 500 140 240 3200 1.0 110 22 200 0.2 0.5

[0045] Pressure: 0.003MPa, feed gas flow: 1000Nm 3 / h

[0046] The high-temperature (400-800°C) calcium carbide furnace gas from the closed calcium carbide furnace is cooled by three jacketed air coolers in series, and the temperature drops to 230-270°C, enters the bag filter for dust removal, and then enters the coke remover, and After heat exchange, the temperature drops to 25°C, and the tar in it solidifies and precipitates out. The pressure of the gas after dedusting and decoking is about 0.005MPa. It is pressurized to 0.05MPa by the blower and e...

Embodiment 2

[0057] Table 4 Composition of raw calcium carbide gas

[0058] Component CO H 2 CO 2 N 2 O 2 CH 4 tar ∑ V% 85.0 6.4 1.8 3.9 1.2 0.7 1.0

[0059] Table 5 impurity components

[0060] Component dust moisture h 2 S Thiol COS CS 2 Thiophene NO x P 4 pH 3 H 3 HCN mg / Nm 3 1.0×10 5 6.5 440 180 290 3500 1.0 80 18 150 0.3 0.3

[0061] Pressure: 0.005MPa, feed gas flow: 5000Nm 3 / h

[0062] The high-temperature (400-800°C) calcium carbide furnace gas from the closed calcium carbide furnace passes through the outer outlet pipe with fins to the ceramic filter. The working temperature of the ceramic filter is 300°C, and the filtration time of the ceramic filter is 5 minutes. For 1 minute, filter and backflush alternately. After passing through the ceramic filter, the dust content of the gas is reduced to 5-10mg / Nm 3 ;

[0063] The subsequent purification and CO purification ...

Embodiment 3

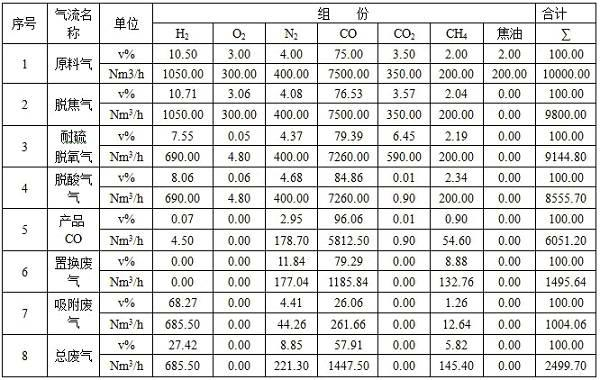

[0068] Table 7 Composition of raw calcium carbide gas

[0069] Component CO H 2 CO 2 N 2 O 2 CH 4 tar ∑ V% 75.0 10.5 3.5 4.0 3.0 2.0 2.0

[0070] Table 8 Impurity Components

[0071] Component dust moisture h 2 S Thiol COS CS 2 Thiophene NO x P 4 pH 3 H 3 HCN mg / Nm 3 0.8×10 5 15 3600 120 230 3750 1.0 150 27 175 0.1 0.1

[0072] Pressure: 0.005MPa, feed gas flow: 10000Nm 3 / h

[0073] Calcium carbide furnace gas purification and CO purification methods are the same as in Example 1, except that the working temperature of the ceramic filter is 500°C; the temperature-swing adsorption system consists of 8 towers; the compressor is pressurized to 1.0MPa and enters the sulfur-resistant deoxidation system; sulfur-resistant catalytic The deoxidation temperature is 300°C and the space velocity is 5000h -1 ; Hydrolytic desulfurization temperature 200 ℃, space velocity 5000h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com