Soil heavy metal pollution conditioner and preparation method thereof

A technology of heavy metals and conditioners, applied in the field of soil conditioning and soil improvers, can solve the problems of waste occupying land resources, high cost, damage to soil structure and ability to fix heavy metals, etc., to achieve simple production process, solve resource waste, and repair The effect of heavy metal pollution on soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation method of soil conditioner

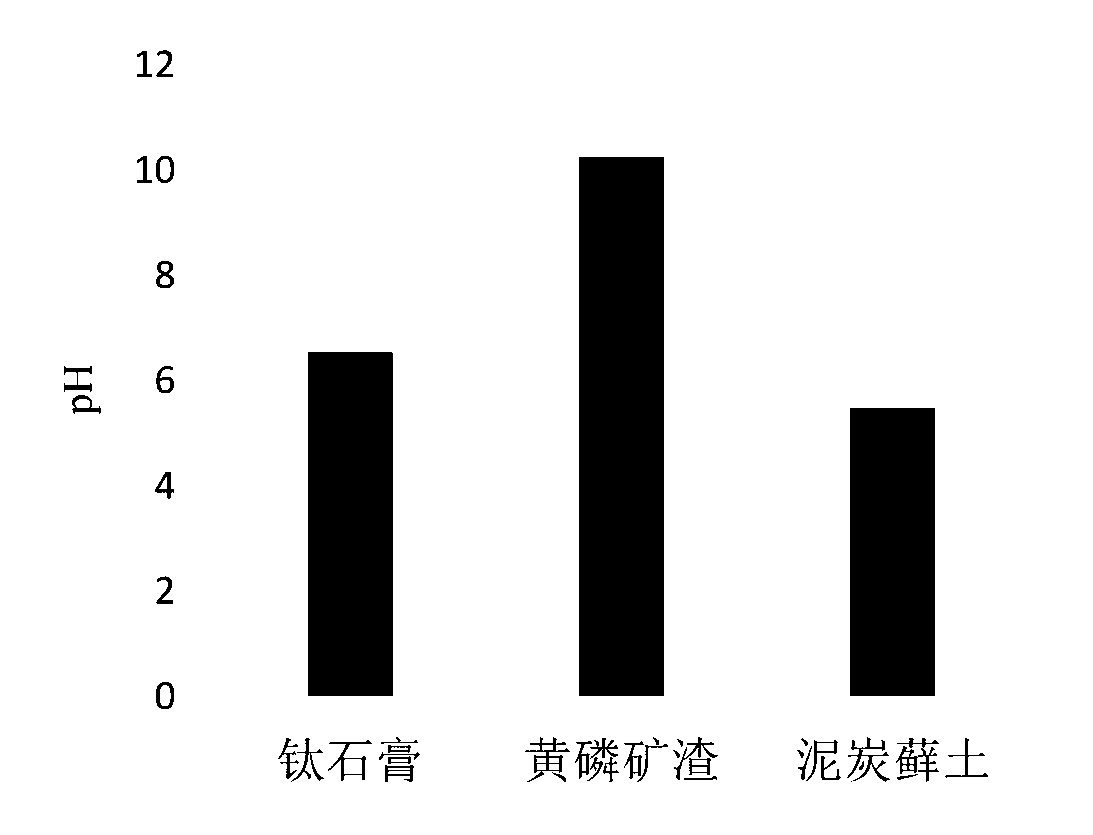

[0037] Component A minerals are mixed with yellow phosphorus slag, sphagnum moss, and titanium gypsum in a mass ratio of 7:2:1.

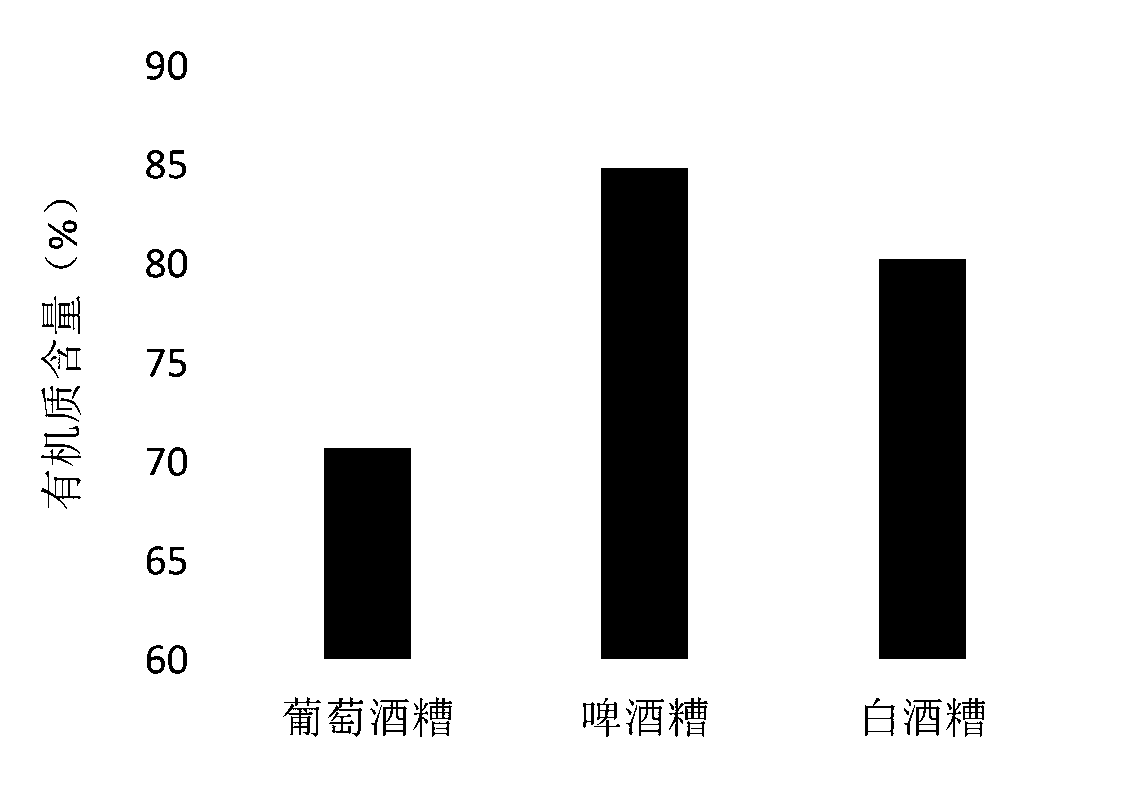

[0038] The mixture of component B is selected from: dry brewer's grains, cow dung, wheat straw, bagasse, bran and mushroom culture materials.

[0039]Mixture of component B, each component is calculated in parts by mass, dry brewer's grains, cow dung, wheat straw, bagasse, bran and mushroom culture medium are ground according to the mass ratio of 2:1:6:2:1:0.1 mixed.

[0040] The active fermented material of component C, the yogurt is commercially available yogurt.

[0041] Active fermentation material of component C, distiller's grains are selected from brewer's grains.

[0042] About 10 g of the prepared mixture was taken out, prepared into a slurry with 1 L of sterilized deionized water, and mixed evenly to obtain a culture solution.

[0043] 10g of component C beer grains and ...

Embodiment 2

[0046] Embodiment 2: the preparation method of soil conditioner

[0047] Component A minerals are mixed with yellow phosphorus slag, sphagnum moss, and titanium gypsum in a mass ratio of 7:1:1.

[0048] The mixture of component B is selected from: dry distiller's grains, cow dung, wheat straw, bagasse, bran and mushroom culture materials.

[0049] Mixture of component B, each component is calculated by mass parts, dry distiller's grains, cow dung, wheat straw, bagasse, bran and mushroom culture material are ground according to the mass ratio of 2:1:5:1:1:0.5 Crushed and mixed.

[0050] The active fermented material of component C, the yogurt is commercially available yogurt.

[0051] The active fermentation material of component C, distiller's grains are white distiller's grains.

[0052] Take about 10 g of the prepared component B mixture, prepare a slurry with 1 L of sterilized deionized water, and mix evenly to obtain a culture solution.

[0053] 10 g of distiller's gra...

Embodiment 3

[0056] Embodiment 3: the preparation method of soil conditioner

[0057] Component A minerals are mixed with yellow phosphorus slag, sphagnum moss and titanium gypsum in a mass ratio of 7:3:1.

[0058] The mixture of component B is selected from: dried brewer's grains, cow dung, soybean straw, bagasse, bran and mushroom culture materials.

[0059] Component B mixture, each component is calculated in parts by mass, brewer's grains, cow dung, soybean straw, bran, bagasse, bran and mushroom culture material according to the quality of 3:1:5:1:1:0.2 Than grind and mix.

[0060] The active fermented material of component C, the yogurt is commercially available yogurt.

[0061] Active fermentation material of component C, distiller's grains are selected from brewer's grains.

[0062] Take about 10 g of the prepared component B mixture, prepare a slurry with 1 L of deionized water, and mix evenly to obtain a culture medium.

[0063] Add 10 g of brewer's grains of component C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com