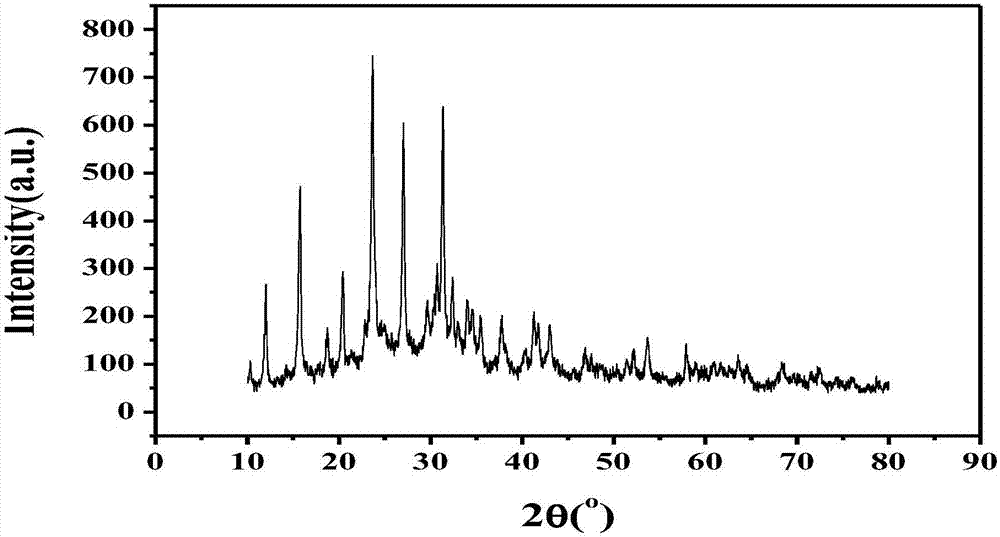

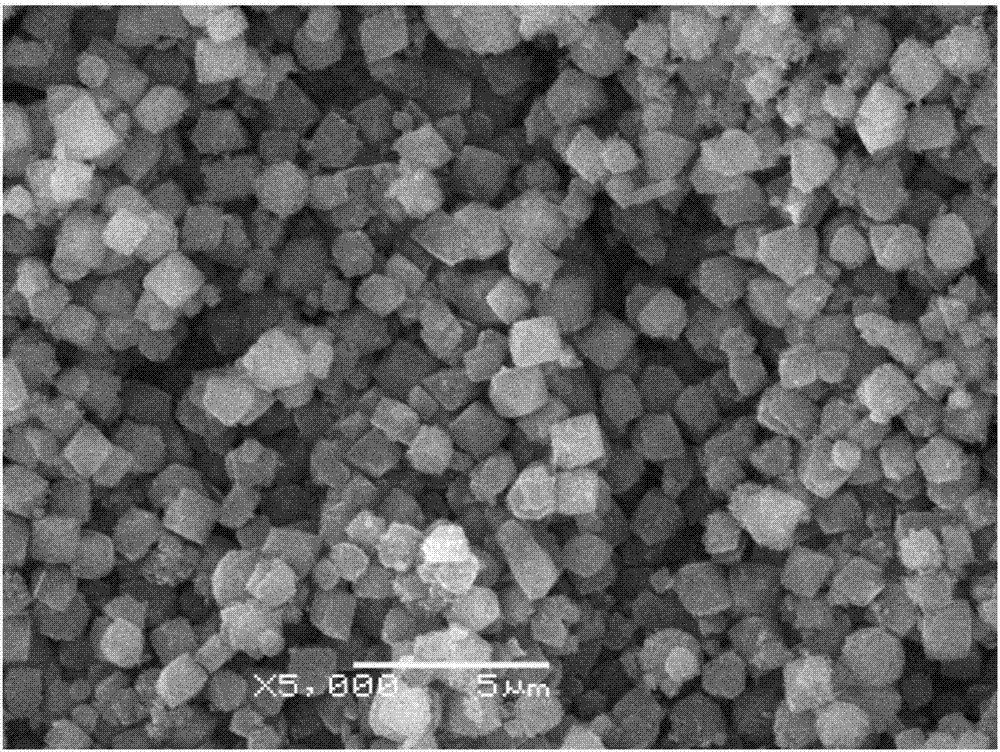

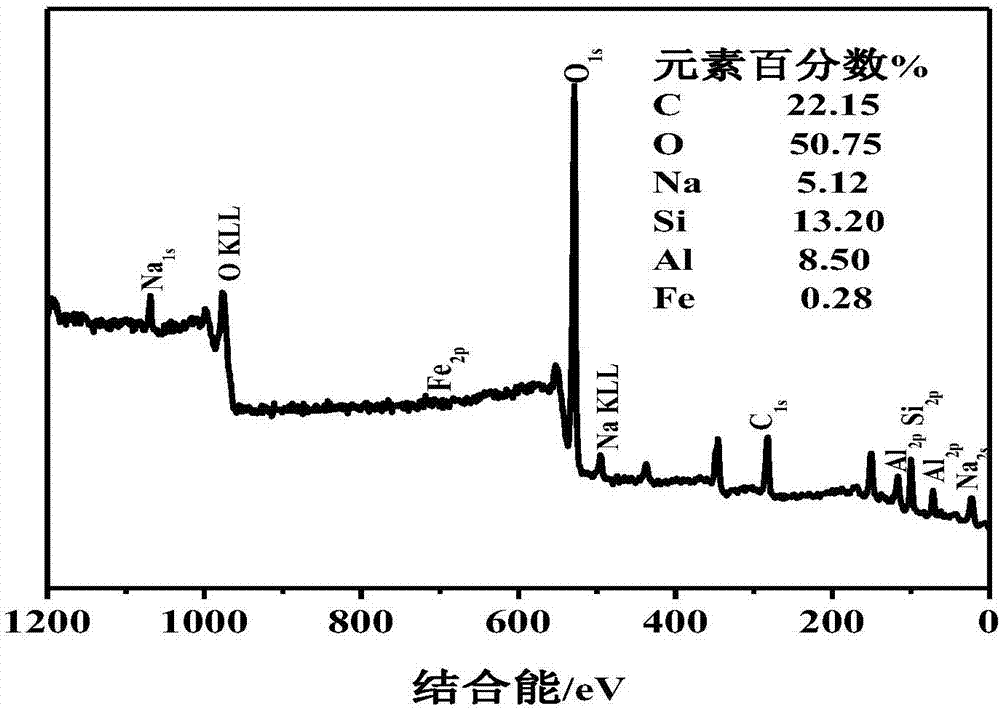

Preparation method and application of magnetic X type molecular sieve

A molecular sieve and magnetic technology, applied in the field of X-type molecular sieve preparation, can solve problems such as high cost, achieve strong commercial competitiveness, strong adsorption performance, and reduce crystallization temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of magnetic X-type molecular sieve of the present invention, the method comprises the following steps:

[0027] Step 1: Grind coal gangue to 300 mesh to 325 mesh and place it in an ash dish, then add sodium carbonate to the ash dish, roast at a temperature of 880°C to 900°C for 2h to 3h, and then grind to obtain pretreatment Sample; the mass ratio of described coal gangue and sodium carbonate is (2~3): 1;

[0028] Step 2: Oxidize the pretreated gangue powder at 350°C to 400°C for 1.5h to 2h, add hydrochloric acid with a mass concentration of 15%, soak at 90°C to 100°C for 2h to 3h, filter, and add H to the filtrate 2 C 2 o 4 / Fe 3+ Oxalic acid with a molar ratio of 4-6 is used for later use; among them, 0.450g-0.675gH 2 C 2 o 4 ;

[0029] Step 3. After washing the solid in step 2, add sodium hydroxide solid in a mass ratio of 1:1 and grind until mixed evenly. Alkaline fusion at 450°C~500°C for 1.5h~2h, add deionized water and C 6 h ...

Embodiment 1

[0036] In this embodiment, the preparation of magnetic X-type molecular sieve by using coal gangue includes the following steps:

[0037] Step 1: Grind the gangue to 325 mesh and place it in the ash dish, then add coal gangue: sodium carbonate = 1:3 sodium carbonate to the ash dish, roast for 2 hours at a temperature of 900° C. and then grind to obtain the preformed processing samples;

[0038] Step 2. Oxidize the pretreated coal gangue powder at 350°C for 2h, add hydrochloric acid with a mass concentration of 15%, soak at 90°C for 2h, filter, and add H to the filtrate 2 C 2 o 4 / Fe 3+ Oxalic acid with a molar ratio of 4, for subsequent use;

[0039] Step 3. After washing the solid in step 2, add sodium hydroxide solid in a mass ratio of 1:1 and grind until mixed evenly. Alkaline fusion at 450°C for 2 hours, add deionized water and C 6 h 8 o 7 / Al 2 o 3 Citric acid with a molar ratio of 0.65 was aged at 70° C. for 4 h; the aforementioned spare filtrate was added, and ...

Embodiment 2

[0045] In this embodiment, the preparation of magnetic X-type molecular sieve by using coal gangue includes the following steps:

[0046] Step 1: Grind the gangue to 325 mesh and place it in the ash dish, then add coal gangue: sodium carbonate = 1:3 sodium carbonate to the ash dish, roast for 2 hours at a temperature of 900° C. and then grind to obtain the preformed processing samples;

[0047] Step 2. Oxidize the pretreated coal gangue powder at 350°C for 2h, add hydrochloric acid with a mass concentration of 15%, soak at 90°C for 2h, filter, and add H to the filtrate 2 C 2 o 4 / Fe 3+ Oxalic acid with a molar ratio of 6, for subsequent use;

[0048] Step 3. After washing the solid in step 2, add sodium hydroxide solid in a mass ratio of 1:1 and grind until mixed evenly. Alkaline fusion at 450°C for 2 hours, add deionized water and C 6 h 8 o 7 / Al 2 o 3 Citric acid with a molar ratio of 0.75 was aged at 60° C. for 5 h; the aforementioned spare filtrate was added, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com