Method for preparing modified activated carbon from coffee residues

A technology of activated carbon and coffee grounds, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low efficiency of activated carbon, secondary pollution, and can only purify a corner of the room, etc., to inhibit the increase of formaldehyde , large specific surface area, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

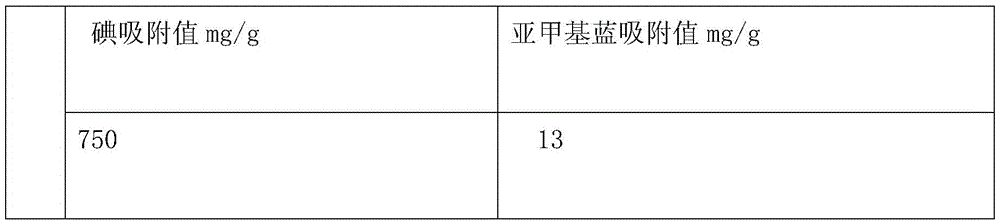

Image

Examples

Embodiment Construction

[0015] A method for preparing modified activated carbon from coffee grounds, comprising the following steps:

[0016] (1), soak the dried coffee grounds with a concentration of 0.5% sodium hydroxide solution at 70-80°C for 1-2 hours, then place them in a small carbonization furnace to isolate the air for heating, and control the heating rate to 4-5°C / min, heat up to 200°C, keep the temperature for 2 hours, then continue to heat up to 440°C at the same heating rate, then keep the temperature for 1-2 hours, and finally cool to room temperature in the absence of air, then you can get carbonized material;

[0017] (2), the carbonized material of step (1) gained is put into agitator, spray potassium chloride solution to it under stirring state, the spray amount of potassium chloride solution is: every kilogram of carbonized material is sprayed into 100ml potassium chloride solution, Described potassium chloride solution is a concentration of 0.5% potassium chloride solution, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com