New method for recycling tungsten-rhenium alloy leftover materials and waste materials

A tungsten-rhenium alloy and scrap technology, which is applied in the field of comprehensive recovery of rare and scattered metal materials, can solve problems such as inability to be recycled and reused in a timely and effective manner, difficulty in making breakthrough progress in the process, and complex technology.

Active Publication Date: 2014-04-16

ULTRA MINOR METALS

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the chemical properties of tungsten and rhenium are very similar, they both exist in the form of acid radical ions in the solution, and the properties of the formed salt compounds are also very similar. Therefore, if the traditional chemical extraction method or ion exchange method is used to achieve complete separation and The purpose of extracting these two metals separately has become more complicated technically, and it is difficult to make breakthroughs in technology.

Before the present invention, the leftovers and waste products of tungsten-rhenium alloy produced by most manufacturers, due to the lack of effective and practical recovery technology, were increasingly piled up and could not be recycled and reused in a timely and effective manner.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

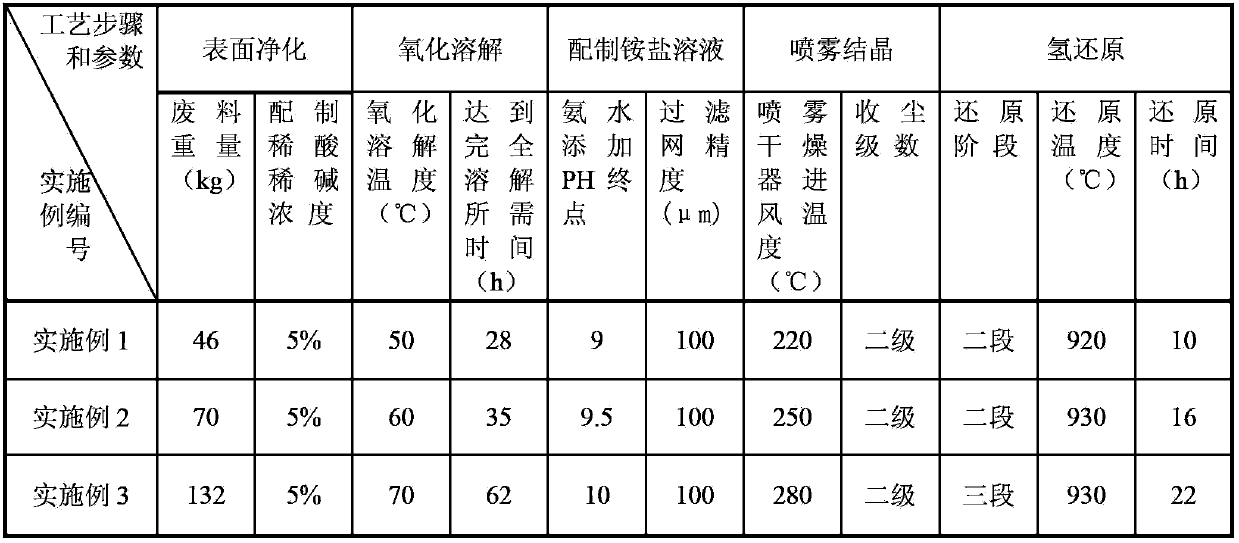

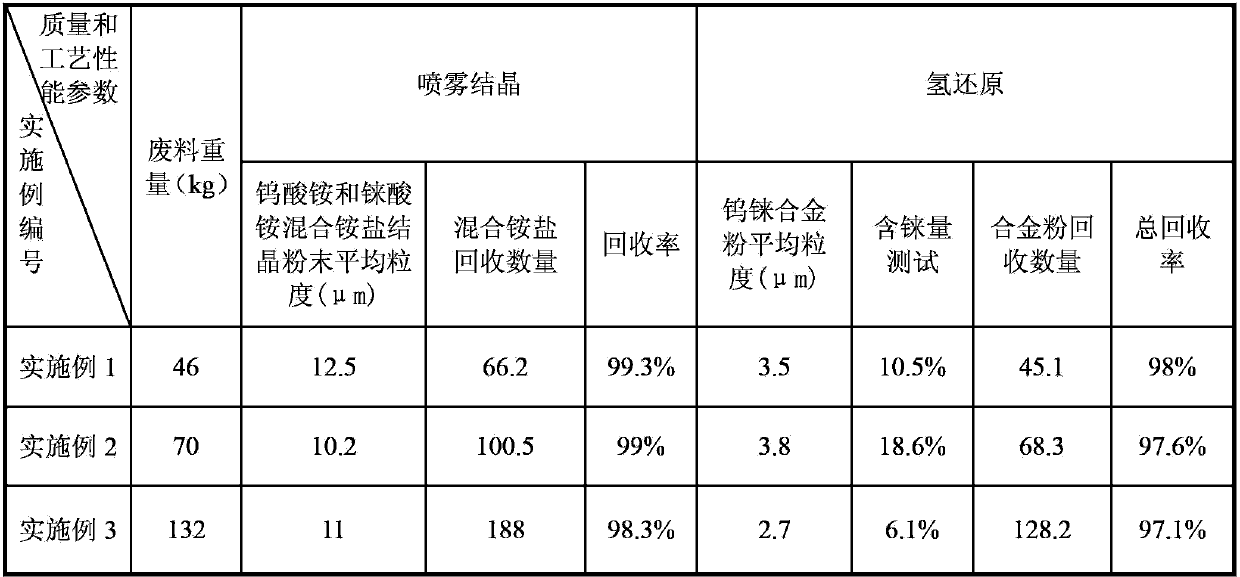

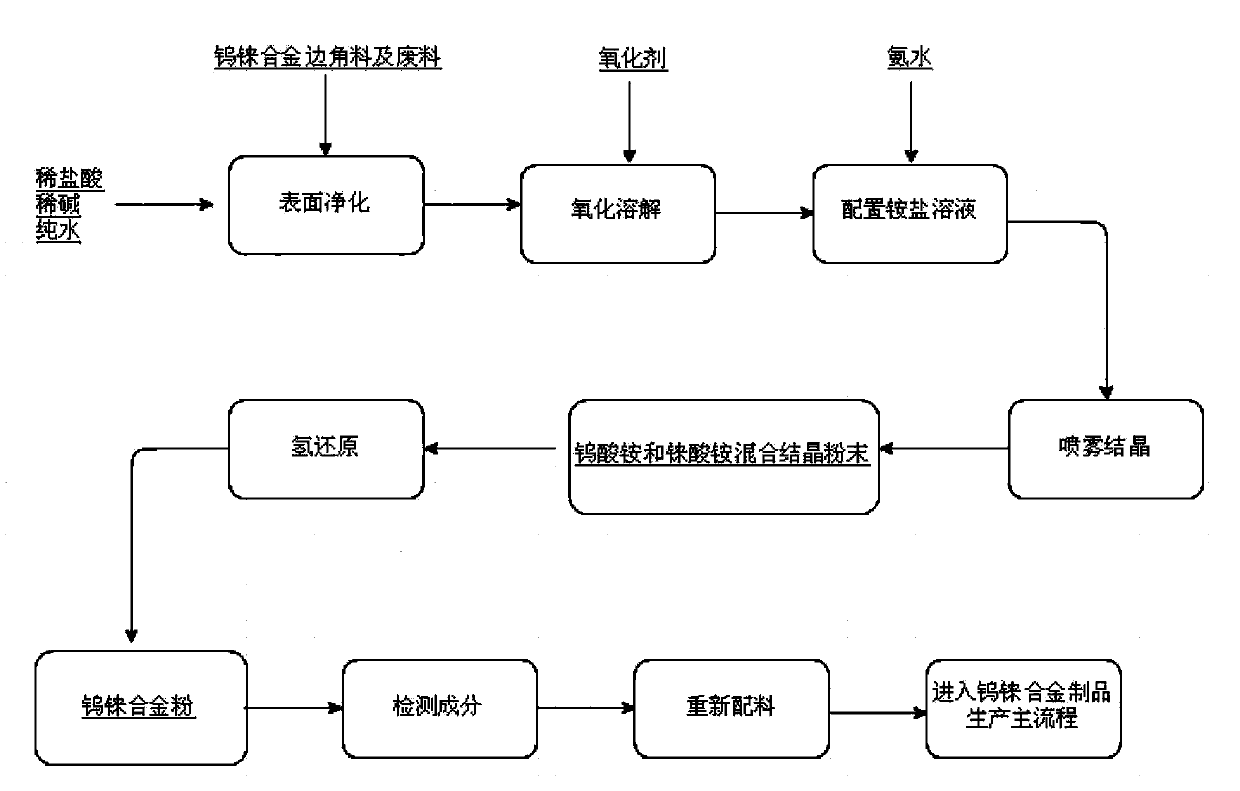

Many leftover materials and waste and defective materials are produced in the tungsten-rhenium alloy machining process. Due to very similar chemical properties of tungsten and rhenium, the separation and extraction with a traditional chemical method is difficult. The present invention originally provides a new idea and a new method for processing and recycling the tungsten-rhenium alloy waste materials, and the recycling rate is more than 97%. The method is as follows: first cleaning the tungsten-rhenium alloy waste material surfaces, then dissolving the tungsten-rhenium alloy waste materials in an oxidizing reagent, adding ammonia to form a mixed ammonium salt solution, controlling the solution PH range and temperature for stabilization of the solution without precipitation of any crystal substances, performing spray drying on the solution to produce mixed tungsten rhenium ammonium salt crystallization powder even in components, performing hydrogen reduction to prepare tungsten rhenium alloy powder, analyzing the rhenium containing components, and again returning into a material mixing process in a main technological cycle. The originally-created special recovery method, compared with traditional methods, has the advantages of short technological route, low recovery cost, high recovery efficiency and good recovery quality.

Description

technical field The invention relates to a comprehensive recycling technology for rare and scattered metal materials, and belongs to the field of metallurgical and chemical material manufacturing. Background technique Both tungsten and rhenium are refractory metals among rare and scattered metals. The melting point of tungsten is the highest among all metals, reaching 3360 degrees; rhenium is next, and its melting point is also as high as 3180 degrees. Because rhenium has excellent high-temperature performance, adding an appropriate amount of rhenium to tungsten to make tungsten-rhenium alloy can significantly improve the strength, hardness and high temperature resistance of the material, and is widely used in the fields of high temperature measurement and high temperature heating. The concentration of rhenium added to tungsten is usually below 26%, and the grades of tungsten-rhenium alloys are WRe25, WRe26, WRe3, and WRe5. Although the content of rhenium in the alloy is n...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B7/00C22B3/04C22B34/36C22B61/00

CPCY02P10/20

Inventor 秦寒梅

Owner ULTRA MINOR METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com