Thorough salt separation crystallization technology and system for high-salt wastewater

A crystallization system, high-salt technology, applied in alkali metal sulfite/sulfate purification, multi-stage water treatment, water/sewage treatment, etc., can solve the problem of high amount of miscellaneous salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

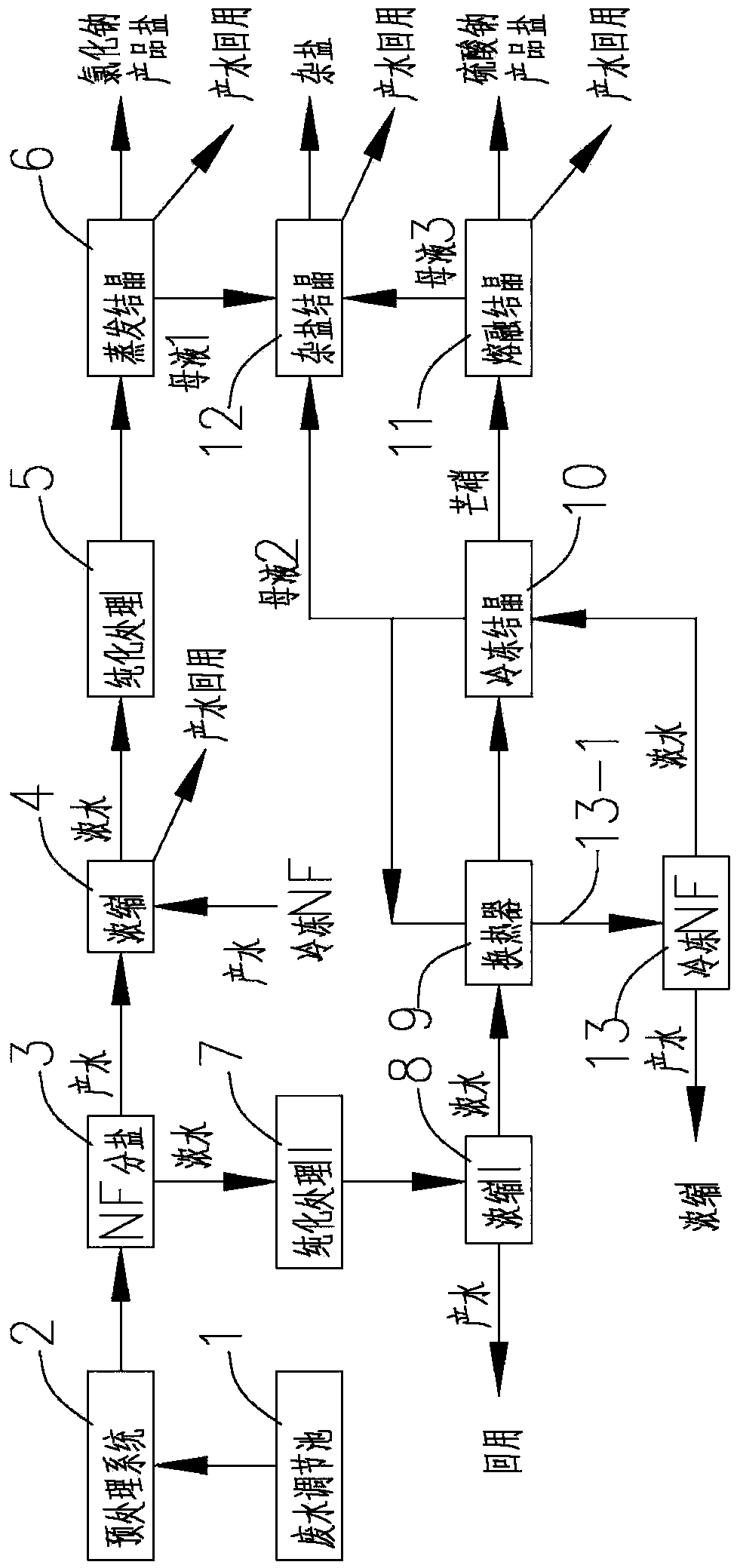

Image

Examples

Embodiment Construction

[0064] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0065] (1) The average concentration of each pollutant in a certain high-salt water wastewater is: COD Cr 60mg / l, Ca 2+ 150mg / l, Mg 2+ 50mg / l, total alkalinity (as CaCO 3 Total) is 600mg / l, full silicon is 35mg / l, TDS is 22000mg / l, Cl - 7000mg / l, SO 4 2- 6400mg / l, Na + It is 7450mg / l.

[0066] (2) After high-efficiency softening and clarification, filter tank filtration, ultrafiltration device, and resin softening, the average concentration of each pollutant in the effluent of the pretreatment system is: COD Cr 52mg / l, Ca 2+ 0.3mg / l, Mg 2+ 0.2mg / l, total alkalinity (as CaCO 3 Total) is 50mg / l, full silicon is 20mg / l, TDS is 21000mg / l, Cl - 6750mg / l, SO 4 2- 6500mg / l, Na + It is 7500mg / l.

[0067] (3) After pretreatment, the wastewater enters the NF salt separation system, and the average concentration of each pollutant i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com