Technological injectant device for controlling flow-induced corrosion failure of pipelines

A flow corrosion and injection technology, applied in the direction of injection device, injection device, feeding device, etc., can solve the problem of poor atomization effect of process injection agent, achieve self-balancing effect, ensure reliability, and reduce corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

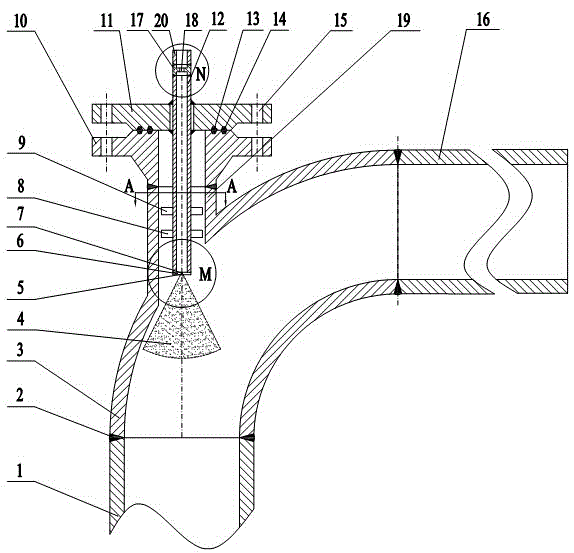

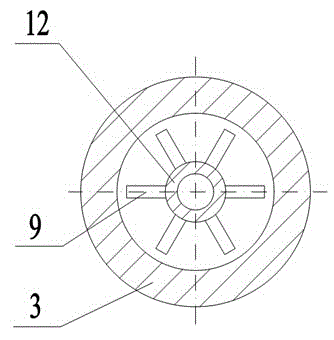

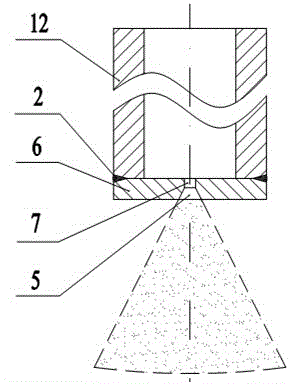

[0021] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes 90 o Elbow 3, injection pipe 12, lower flange 10, upper flange 11, atomizing nozzle 6, restrictor orifice 17 and injection sleeve 19; 90 o Elbow 3 backs are vertically provided with injection sleeve pipe 19, and injection sleeve pipe 19 lower ends and 90 o The elbow 3 is cast to form an integrated combined elbow. The upper end of the injection sleeve 19 is fixedly connected to the lower end surface of the lower flange 10 through the butt welding seam 2 . The first sealing ring 13 and the second sealing ring 14, both sealing rings are "O" type elastic sealing rings, the upper flange 11 and the lower flange 10 are connected by bolts through the bolt holes 15 around, and the injection pipeline 12 is in turn Insert from upper flange 11, lower flange 10, injection sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com