High-salt wastewater salt separation system and process

A high-salt wastewater and salt separation technology, which is applied in the direction of alkali metal sulfite/sulfite, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of unsatisfactory natural evaporation effect and difficult to achieve production Standards, reducing the economic benefits of enterprises and other issues, to achieve the effect of reducing the content of sulfate ions, avoiding damage, reducing investment costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

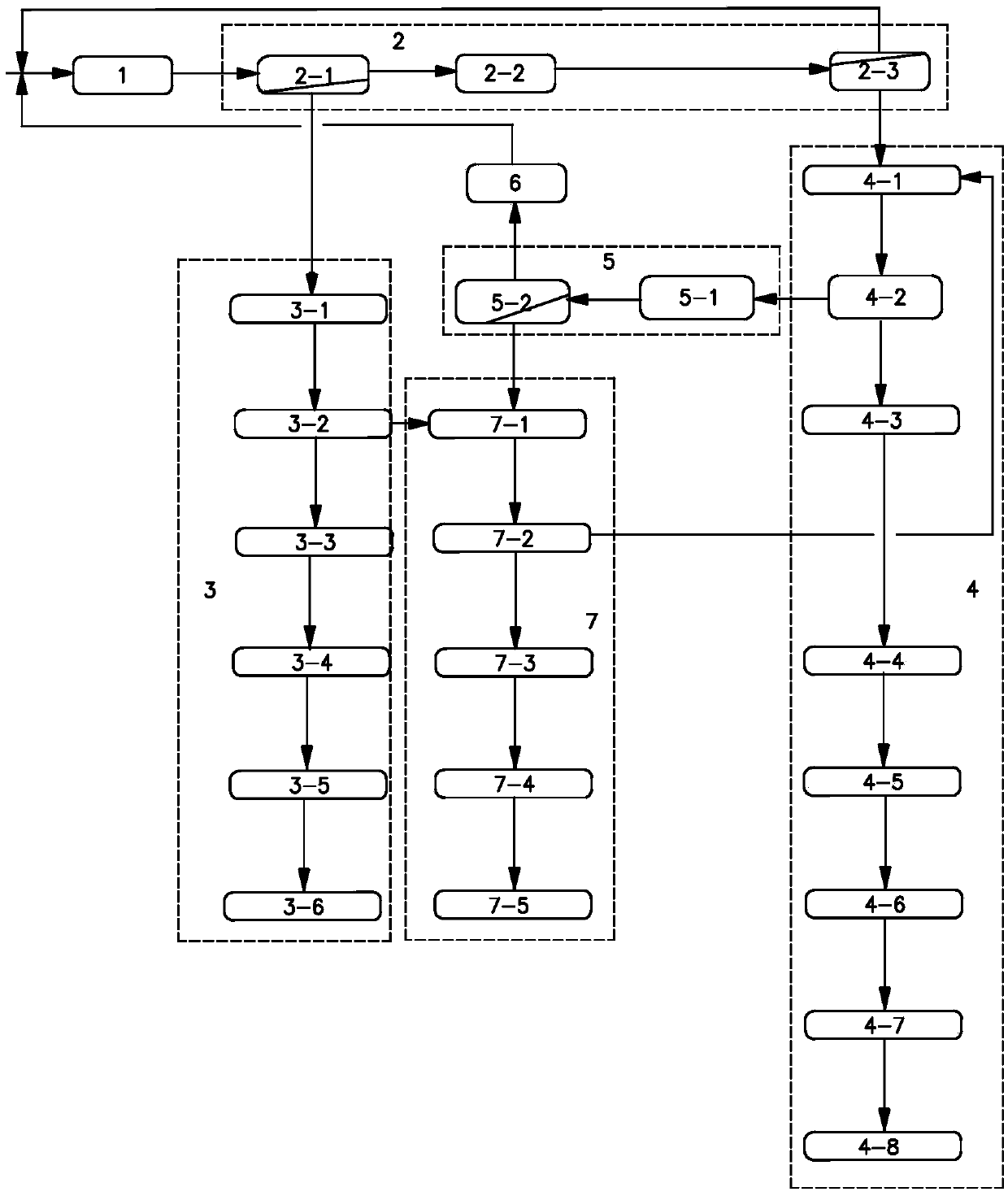

[0035] Such as figure 1 The high-salt wastewater salt separation system shown includes raw water tank 1, nanofiltration unit 2, sodium chloride evaporation crystallization unit 3, sodium sulfate evaporation crystallization unit 4, organic concentration unit 5, ozone reaction tank 6, mixed salt evaporation crystallization unit 7;

[0036] The water outlet of the raw water tank 1 communicates with the water inlet of the primary nanofiltration membrane device 2-1 of the nanofiltration unit 2, and a core filter is arranged on the pipeline connecting the raw water tank 1 and the primary nanofiltration membrane device 2-1 , the water outlet of the primary nanofiltration membrane device 2-1 communicates with the water inlet of the sodium chloride evaporation raw water pool 3-1 of the sodium chloride evaporation crystallization unit 3;

[0037] The outlet of the produced water of the secondary nanofiltration membrane device 2-3 of the nanofiltration unit 2 is connected with the water...

Embodiment 2

[0050] The high-salt wastewater salt separation system described in Example 1 is used to treat high-salt wastewater, including the following steps: process one nanofiltration; process sodium dichloride crystallization and sodium sulfate crystallization; process three organic concentration; process four ozone oxidation; process five Miscellaneous salt crystals; of which:

[0051] Process 1 nanofiltration: the pH in the raw water tank 1 is 7, the TDS concentration is 45000mg / L, and the Cl - Concentration 10000mg / L, SO 4 2- Concentration is 15000mg / L, COD is 1000ppm, total hardness is 1ppm high brine is sent in the first-level nanofiltration membrane device 2-1 of high-salt wastewater salinization system, and the first-level nanofiltration treatment is carried out under the pressure of 3MPa to obtain The primary nanofiltration product water and the primary nanofiltration concentrated water, and the primary nanofiltration product water mainly contains sodium chloride, and the pr...

Embodiment 3

[0058] The high-salt wastewater salt separation system described in Example 1 is used to treat high-salt wastewater, including the following steps: process one nanofiltration; process sodium dichloride crystallization and sodium sulfate crystallization; process three organic concentration; process four ozone oxidation; process five Miscellaneous salt crystals; of which:

[0059] Process 1 nanofiltration: the pH in the raw water tank 1 is 7, the TDS concentration is 50000 mg / L, and the Cl - Concentration 13000mg / L, SO 4 2- Concentration of 17000mg / L, COD of 800ppm, total hardness of 2ppm high salt water is sent to the first-stage nanofiltration membrane device 2-1 of the high-salt wastewater salt separation system, and the first-stage nanofiltration treatment is carried out under the pressure of 3MPa to obtain a First-level nanofiltration product water and first-level nanofiltration concentrated water, and the primary nanofiltration product water mainly contains sodium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com