Flying ash harmless treatment resource recycling utilization device and treatment method

A harmless treatment and recycling technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as environmental hazards, irregular markets, inadequate supervision, etc. The effects of chlorine product safety, high detoxification efficiency, and pure water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

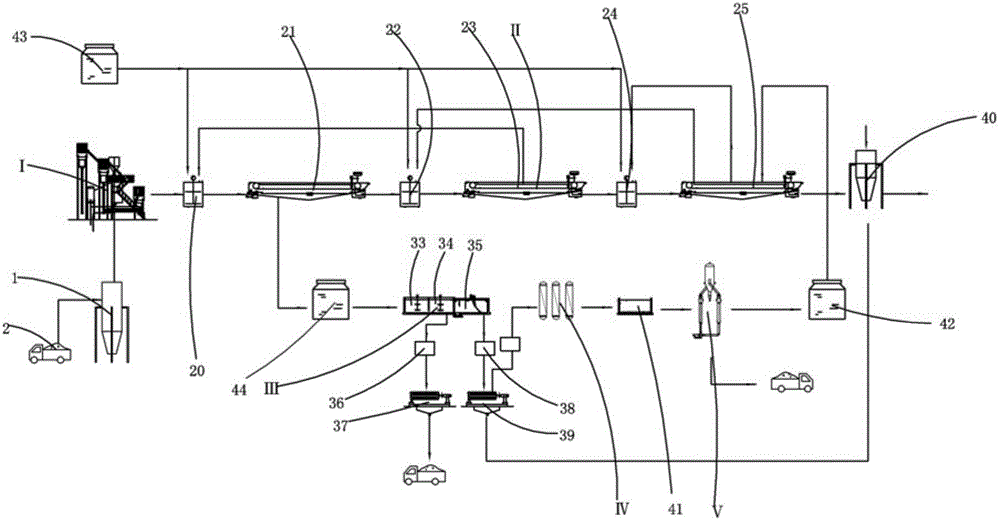

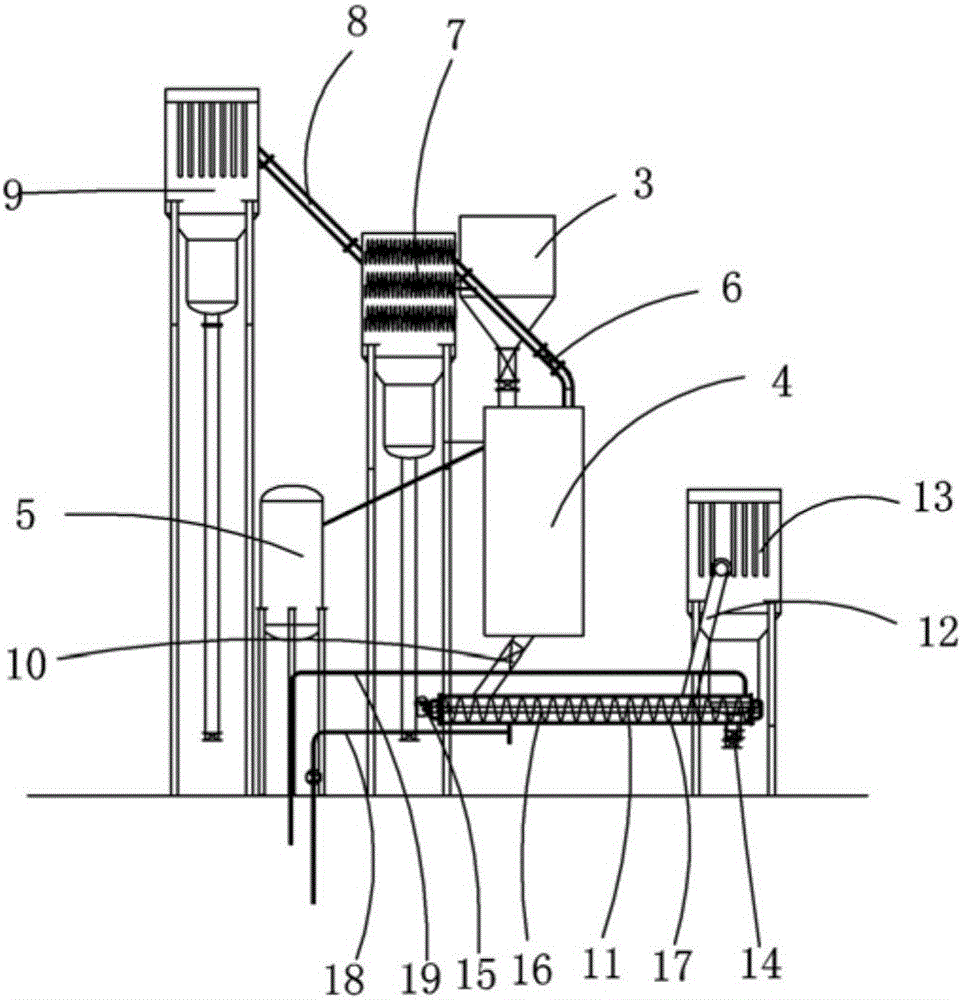

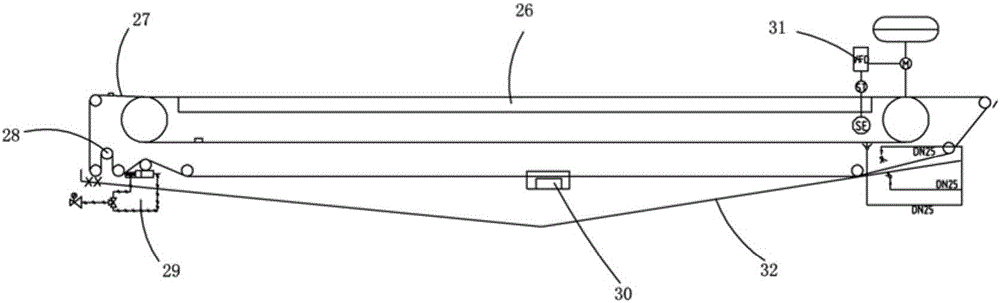

[0036] See attached Figure 1~3 , a fly ash harmless treatment resource recycling device, which includes sequentially connected solid-phase catalytic dechlorination detoxification and removal of dioxin system Ⅰ, waste incineration fly ash three-stage water elution desalination system Ⅱ, heavy metal removal system Ⅲ, membrane Distillation concentration system IV and salt crystallization system V; the solid-phase catalytic dechlorination detoxification and dioxin removal system uses mineral catalysts to induce dioxin dechlorination and remove dioxins in fly ash. After dechlorination, the phenyl parent A non-toxic and harmless high-polymer product is generated through a condensation reaction; the waste incineration fly ash three-stage water elution desalination system washes off a large amount of salt in the fly ash from which dioxins have been removed, and in the three-stage water washing filtrate after water washing There are also some heavy metal ions remaining; the heavy meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com