Stripping tower for CO conversion condensate

A technology of condensate and stripper, which is applied in the field of CO-shift condensate stripper, can solve the problems of increasing the water consumption of stripping gas condensation cycle, the consumption of low-pressure steam, the complex control of the stripper operating system, and the lack of stability. The effect of prolonging the period of stable operation, solving the blockage of ammonium salt crystals and reducing the dosage

Active Publication Date: 2013-03-13

CHINA PETROLEUM & CHEM CORP +2

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The main disadvantages of setting up a single stripper are as follows: First, the stripping gas stripped from the top of the tower by the CO shift condensate stripper contains both carbon dioxide and ammonia, so that in the subsequent condensation process, carbon dioxide and ammonia are easily Ammonium salt crystals are generated, which block the pipes and condensers; followed by the conversion of condensate entering the condensate stripping tower from different upstream equipment, and the mixed flow of several fluids with different temperatures, simultaneously from the condensate stripping tower The upper part of the side wall is added at one time, and the temperature gradient of different streams is not fully utilized, that is to say, the temperature and energy utilization of several streams is not scientific and reasonable. As a result, the stripping gas temperature of the condensate stripping tower is relatively high. High, increasing the water consumption of the condensation cycle of th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

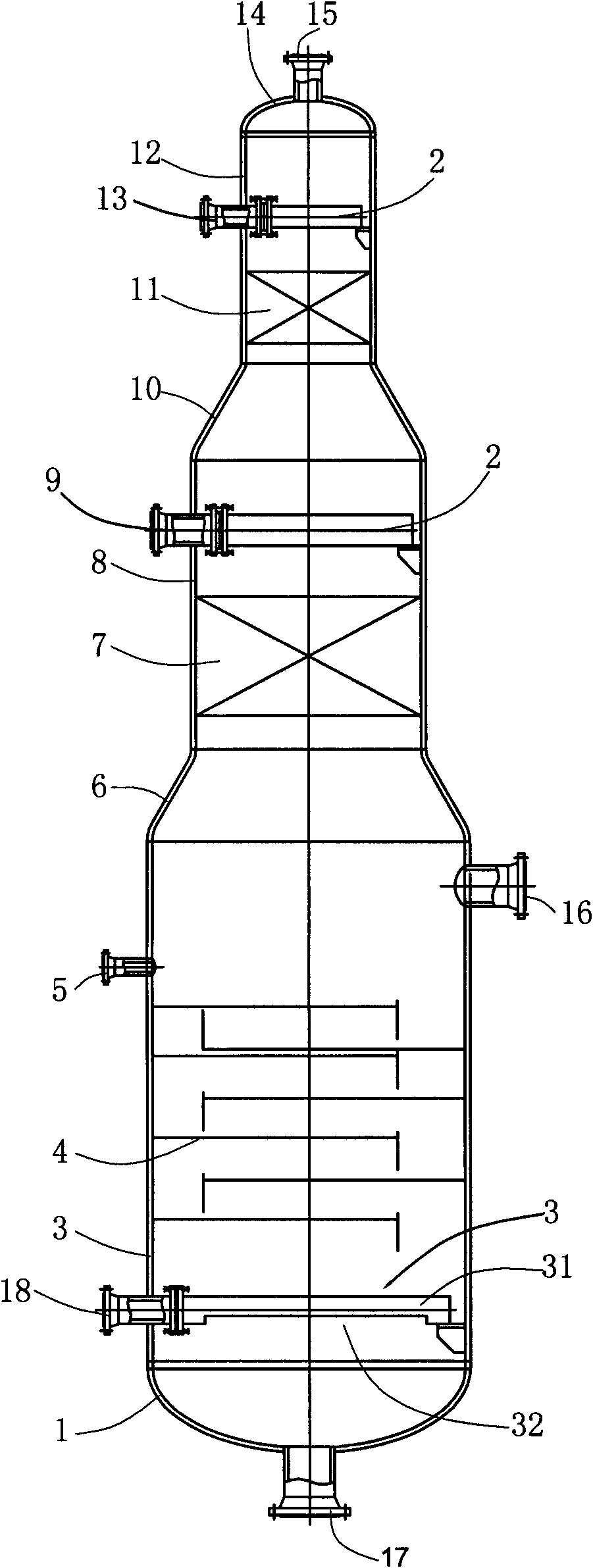

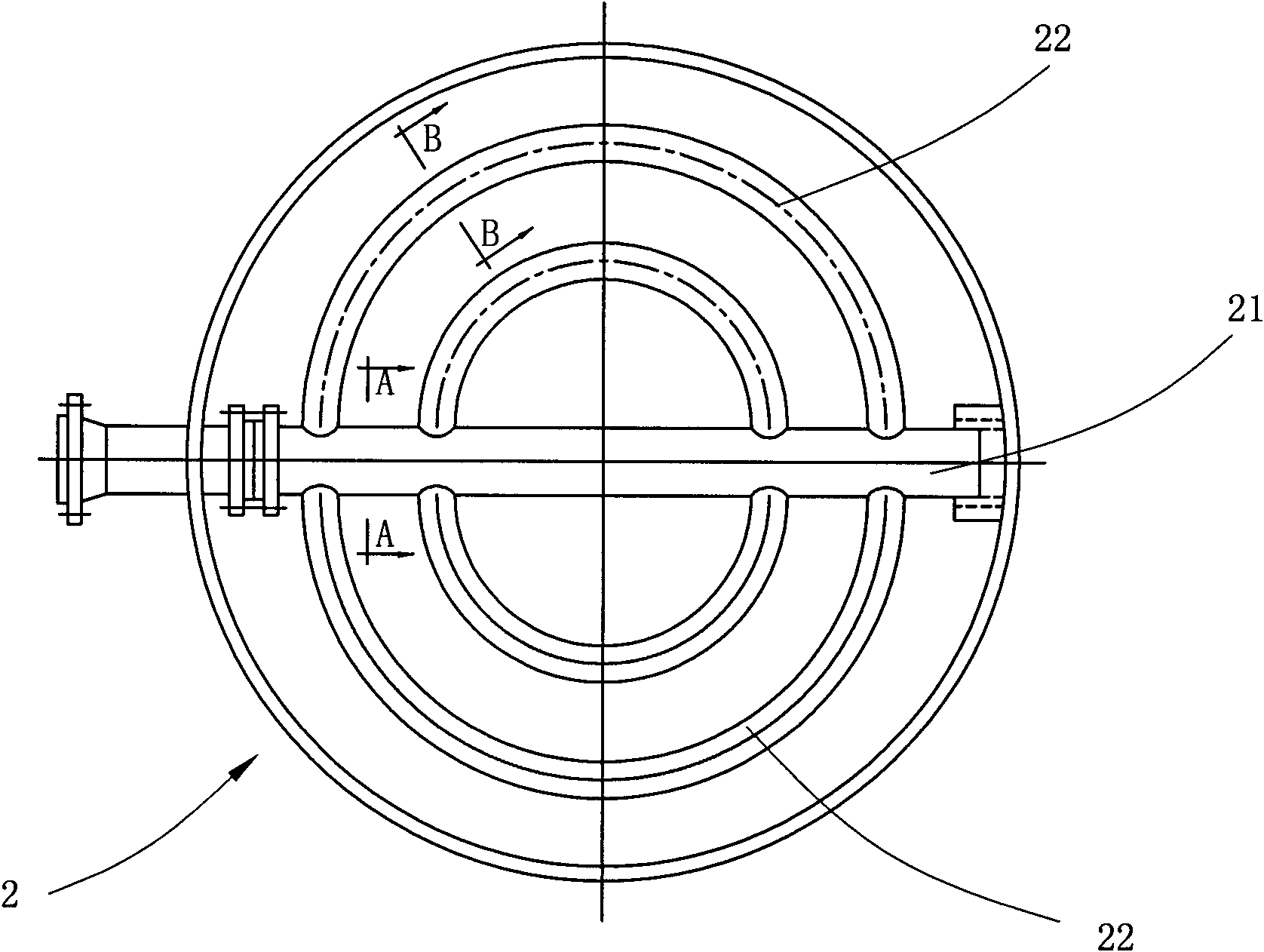

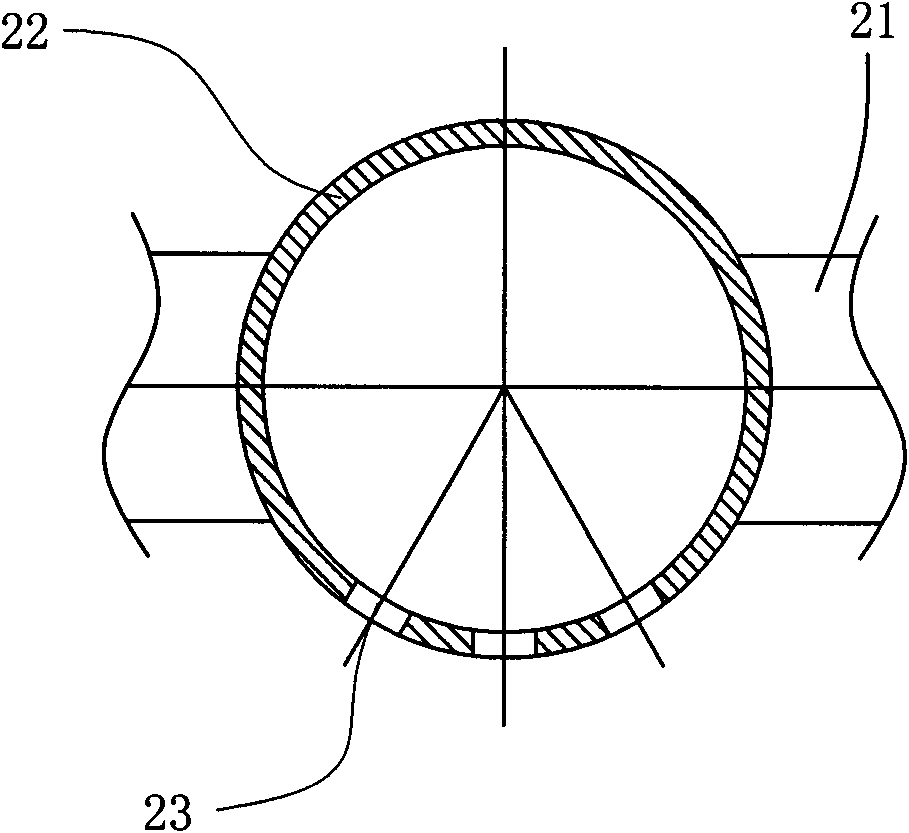

The invention relates to a stripping tower for a CO conversion condensate, which comprises a tower body, wherein a first steam stripping gas outlet; a liquid outlet, through which conversion steam stripping condensate is discharged, is formed in the bottom of the tower body; a low pressure steam inlet is formed in the lower part on the side wall of the tower body; and a plurality of condensate inlets, through which condensate enters into the tower body, are formed in the middle upper part on the side wall of the tower body. The stripping tower is characterized in that the number of the condensate inlets is large; the condensate inlets are arranged at intervals side by side; and a second steam stripping gas outlet, through which ammonia steam is discharged, is formed in the middle on the side wall of the tower body. Compared with the prior art, the invention has the advantages that the potential temperatures and the energy gradients of different conversion condensates are utilized scientifically and reasonably, so as to save the consumption of low pressure steam used for steam stripping, reduce the consumption of circulating cooling water used for a rear system to condensate steam stripping gas, eliminate a heat recovering device which is necessary in a post process, avoid the phenomenon that carbon dioxide and ammonia exist at the same time in a condenser system, effectively solve the problem of blockage caused by ammonium salt crystallization, and prolong the stable operation period of a conversion device.

Description

technical field [0001] The invention relates to a CO shift condensate stripper. Background technique [0002] The synthesis gas produced by coal gasification or residual oil gasification contains a relatively high concentration of CO gas. When the synthesis gas is used to produce products such as methanol or urea, a CO conversion unit is required to convert part or absolute of the synthesis gas by reacting with water vapor. Most of the CO is removed, producing hydrogen gas equimolar to CO. In order to increase the conversion rate and control the bed temperature in the shift reaction, it is generally required to add an excess of water vapor, and the remaining water vapor in the shift reaction is cooled in the waste heat recovery system to become a condensate, which is called a shift condensate. Usually, the shift condensate contains a small amount of gases such as ammonia and carbon dioxide dissolved in it, and it needs to be sent to the shift condensate stripping tower to b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/04C02F1/20B01D3/38

CPCY02P70/10

Inventor 许仁春陈莉施程亮张骏驰黄彬峰陆亚东李绍红唐永超徐洁卢新军张晓宁

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com