Coal water slurry gasification wastewater salt separation and crystallization zero discharge treatment system and coal water slurry gasification wastewater salt separation and crystallization zero discharge treatment method

A treatment system and crystallization system technology, applied in the field of coal gasification, can solve problems such as easy dissolution, pollutant leakage accidents, complex salt components, etc., and achieve the effect of improving recovery rate and purity, reducing investment and construction costs, and optimizing the crystallization system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

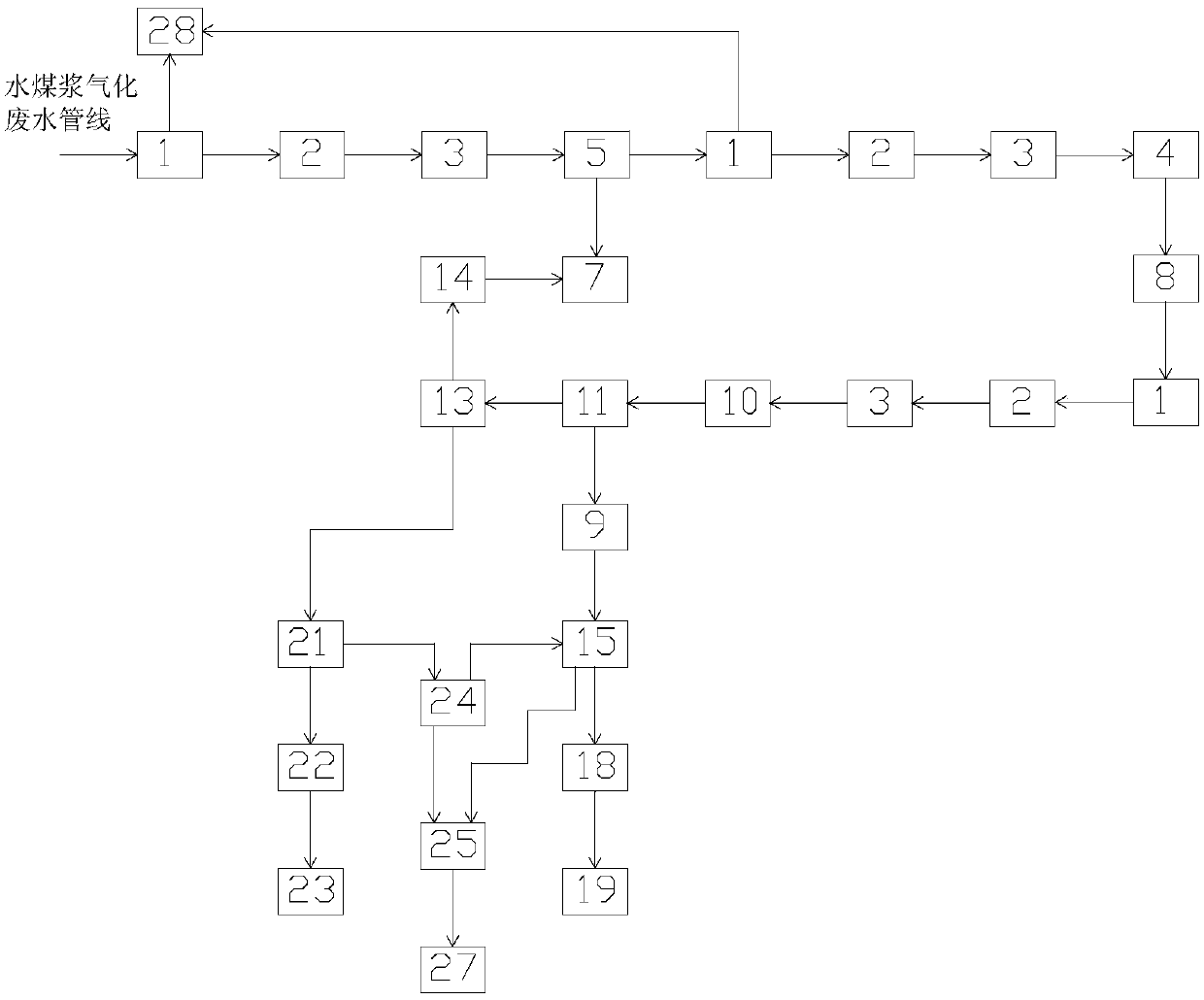

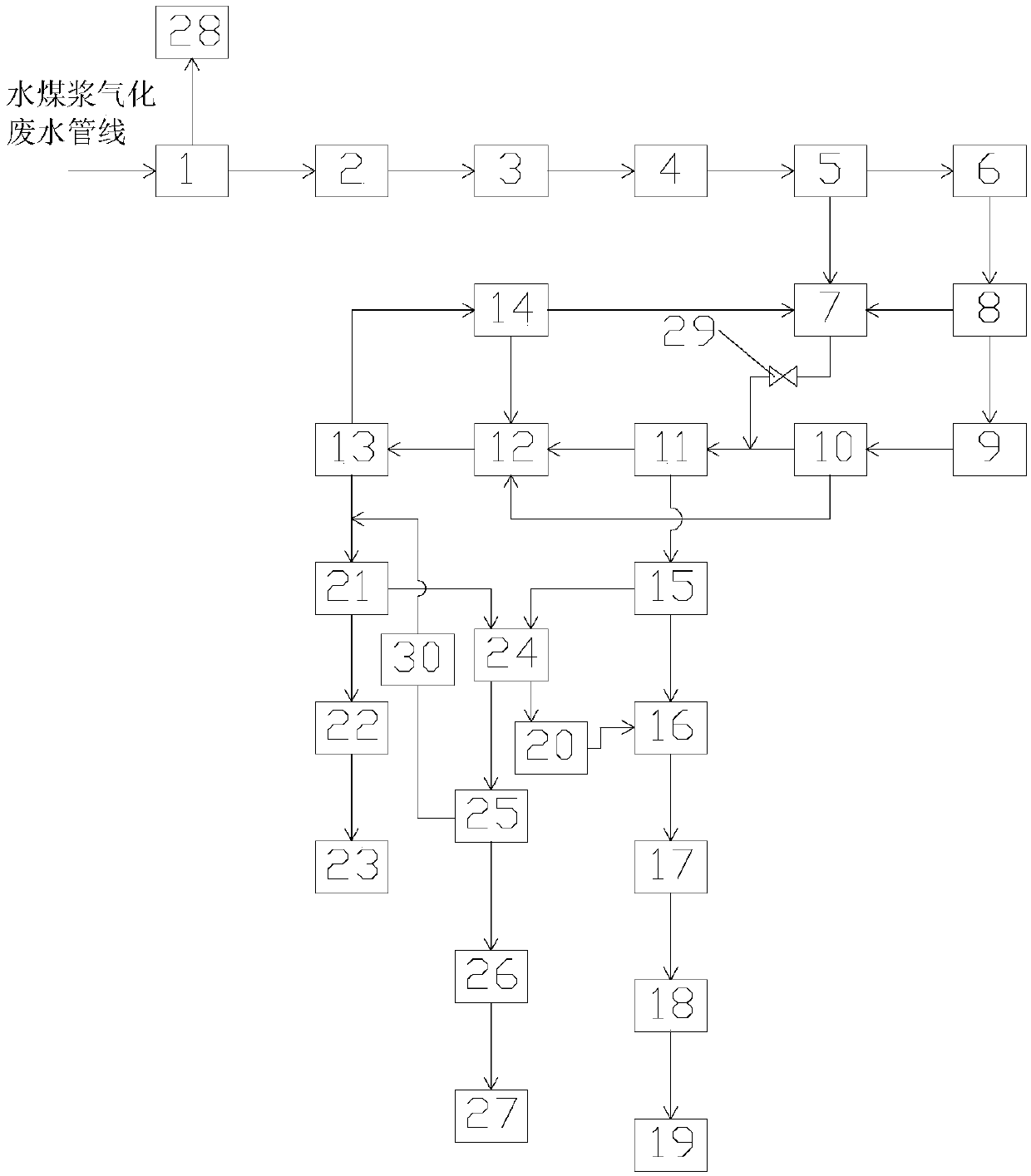

[0032] Such as figure 2 As shown, the coal water slurry gasification wastewater salt separation and crystallization zero discharge treatment system includes a pretreatment system, a salt separation system, a Glauber's salt crystallization system and a salt crystallization system;

[0033] The pretreatment system can remove most of the total hardness, total alkalinity, heavy metal ions and suspended solids as well as some silica, fluoride ions and organic matter in the wastewater to ensure the normal and stable operation of the subsequent system; the pretreatment system includes chemical softening equipment 1 , filter equipment and ion exchange equipment 4, the water inlet of the chemical softening equipment 1 is connected with the coal water slurry gasification wastewater pipeline, the water outlet of the chemical softening equipment 1 is connected with the water inlet of the filter equipment, and the filter equipment includes a V-shaped filter tank 2 and Ultrafiltration equi...

Embodiment 2

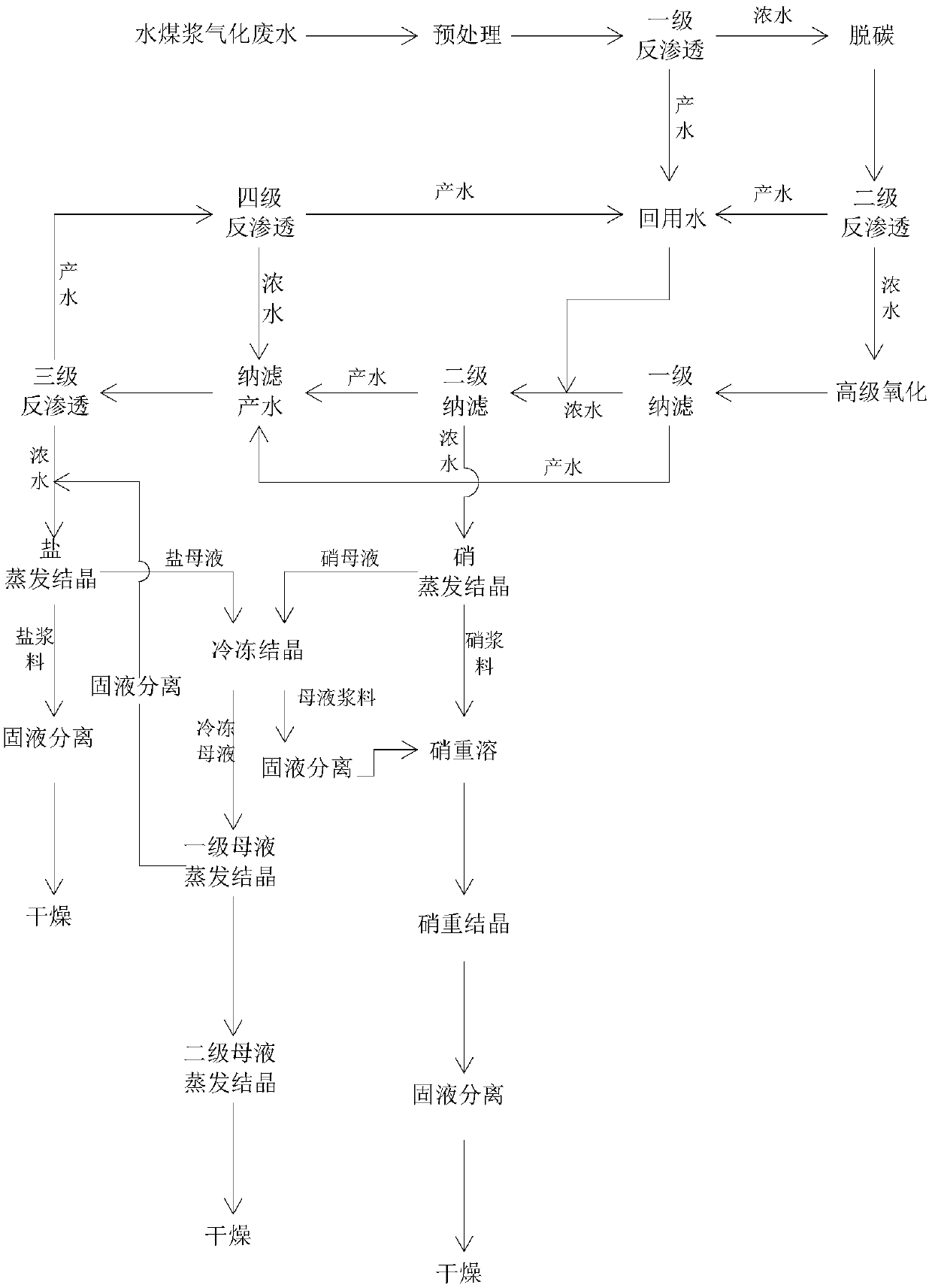

[0040] Utilize the zero-discharge treatment method of coal-water slurry gasification wastewater salt separation crystallization carried out in embodiment 1, such as image 3 As shown, it includes the following steps:

[0041] S1. Pretreatment: After the coal-water slurry gasification wastewater is homogeneous and equalized in the adjustment tank, it enters the pretreatment system for hard and turbidity removal, silicon removal, pH adjustment, and organic matter removal. The details are as follows:

[0042] a1. Chemical softening: Coal-water slurry gasification wastewater is transported to chemical softening equipment 1 for treatment of hardening and turbidity removal, silicon removal, and organic matter removal to obtain chemically softened water. The index of chemically softened water is Ca 2+ ≤50.00mg / l, Mg 2+ ≤50.00mg / l, SiO 2 ≤15.00mg / l, turbidity≤20NTU; the obtained sludge is transported to filter press 28 for dehydration to obtain dewatered sludge;

[0043] a2. Filtra...

Embodiment 3

[0055] Utilize the zero-discharge treatment method of coal-water slurry gasification wastewater salt separation crystallization carried out in embodiment 1, such as image 3 As shown, it includes the following steps:

[0056] S1. Pretreatment: After the coal-water slurry gasification wastewater is homogeneous and equalized in the adjustment tank, it enters the pretreatment system for hard and turbidity removal, silicon removal, pH adjustment, and organic matter removal. The details are as follows:

[0057] a1. Chemical softening: Coal-water slurry gasification wastewater is transported to chemical softening equipment 1 for treatment of hardening and turbidity removal, silicon removal, and organic matter removal to obtain chemically softened water. The index of chemically softened water is Ca 2+ ≤50.00mg / l, Mg 2+ ≤50.00mg / l, SiO 2 ≤15.00mg / l, turbidity≤20NTU; the obtained sludge is transported to filter press 28 for dehydration to obtain dewatered sludge;

[0058] a2. Filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com