Multifunctional supercritical water enhanced oxidation system for degradation-resistant nitrogen-containing and high-salt organic pollutants

A technology of supercritical water oxidation and organic pollutants, applied in water pollutants, water/sewage treatment, oxidized water/sewage treatment, etc. Reduce investment and avoid the effect of increased aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

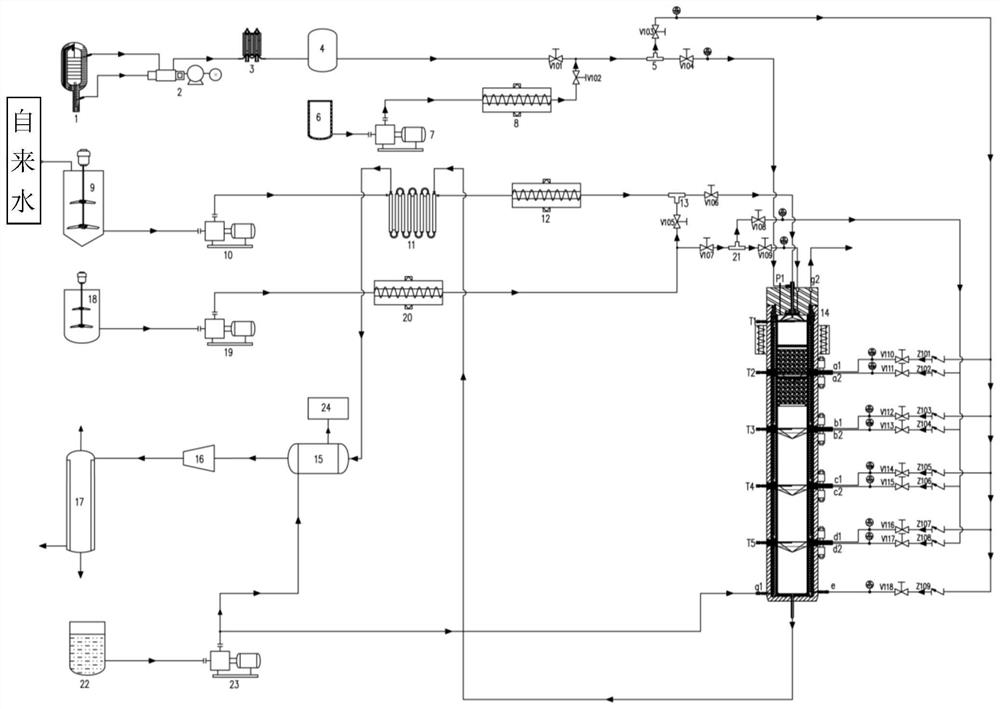

[0060] This example takes supercritical water oxidation technology to treat typical nitrogen-containing organic compound pyridine as an example, and explains in detail the multifunctional supercritical water enhanced oxidation system:

[0061] 1) Add appropriate tap water to the material blending tank to prepare the reactant pyridine according to the required concentration, and turn on the agitator to stir evenly, and then pressurize it to about 25MPa through the material high-pressure pump. The material first enters the outer tube of the preheater for preheating in the first stage. Since the temperature of the material in the supercritical water oxidation reactor is not enough to preheat the material to the required reaction temperature at one time in the initial stage of the reaction, it needs to be heated again. The high-pressure material is preheated in the second stage by the material heater (preheated to about 400°C). After the material is preheated and boosted, it enters...

Embodiment 2

[0067] The difference from Example 1 is that in step 1), when the material solution to be treated contains inorganic salt ions, the material is prepared by adding appropriate tap water in the material preparation tank according to the required concentration and mixed evenly, and then passes through the material solution. The high-pressure pump pressurizes it to about 25MPa, and then the high-pressure cold material directly enters the material channel at the end cover of the supercritical water oxidation reactor, and is sprayed onto the initial reaction plane through the atomization of the spiral atomizing nozzle, and opens at the same time The heater on the upper part of the supercritical water oxidation reactor directly heats the material in the reactor to the reaction temperature.

[0068] In step 4), according to the concentration of the required alcohol fuel (methanol, ethanol, ethylene glycol, isopropanol), add appropriate tap water in the medicament preparation tank for d...

Embodiment 3

[0071] The difference from Example 1 is that in step 2), the valve V101 is closed and the valve V102 is opened. After the hydrogen peroxide in the hydrogen peroxide storage tank is pressurized to about 25MPa by a high-pressure pump, it is determined whether it is necessary to pass Use a hydrogen peroxide heater to preheat it, and then determine whether it is necessary to inject oxygen into the reactor in sections, and the remaining steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com