Process for treating low-temperature condensate at conversion section

A low-temperature condensation and treatment process technology, applied in water/sewage treatment, heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the blockage of pipelines and condensation systems, cannot be directly discharged, and condensate has no reception Users and other issues, to achieve the effect of reducing device energy consumption and reducing the content of H2S

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

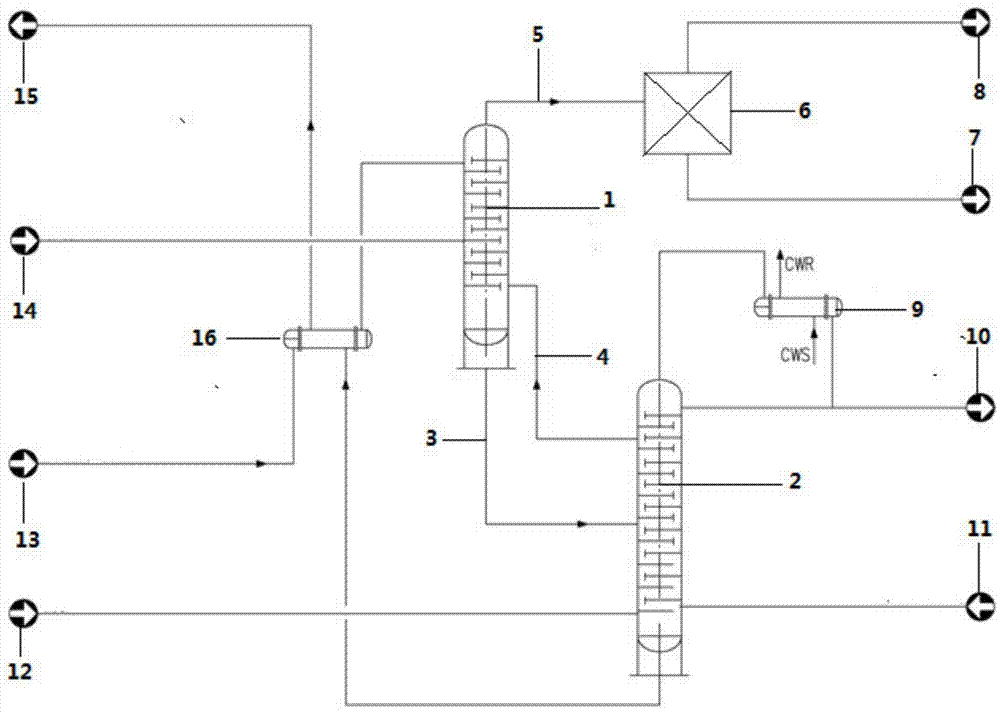

[0022] Attached below figure 1 The present invention is further described.

[0023] Low temperature shift condensate (13) from upstream with NH 3 The condensate at the bottom of the stripper (2) passes through the heat exchanger (16) and heats up to 90°C to enter the CO 2 At the top of the stripping tower (1), the clean condensate (15) produced during the heat exchange is sent out to the section; the vaporized high flash gas (14) enters the CO 2 The middle part of the stripping tower (1); the acid gas produced at the top of the tower is transported to the condensation separation device (6) through the connecting pipeline three (5), and is separated into condensate (7) and non-condensable gas ( 8), the condensate (7) is sent back to the gasification section (not shown in the figure); CO 2 The ammonia-rich condensate at the bottom of the stripper (1) enters the NH through the connecting line one (3) depending on the height difference. 3 The middle and upper part of the strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com