Concentrating and impurity removing method for dilute sulfuric acid in titanium dioxide powder production process by employing sulfuric acid process

A technology of titanium dioxide and dilute sulfuric acid, which is applied in the field of concentration and impurity removal of dilute sulfuric acid in the production process of sulfuric acid titanium dioxide, can solve the problems of long process flow, many equipment, large investment, etc., and achieve shortened process flow and high heat transfer efficiency , the effect of investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition of titanium dioxide dilute sulfuric acid is as follows: liquid density: 1380 (kg / cm 3 )

[0028] components

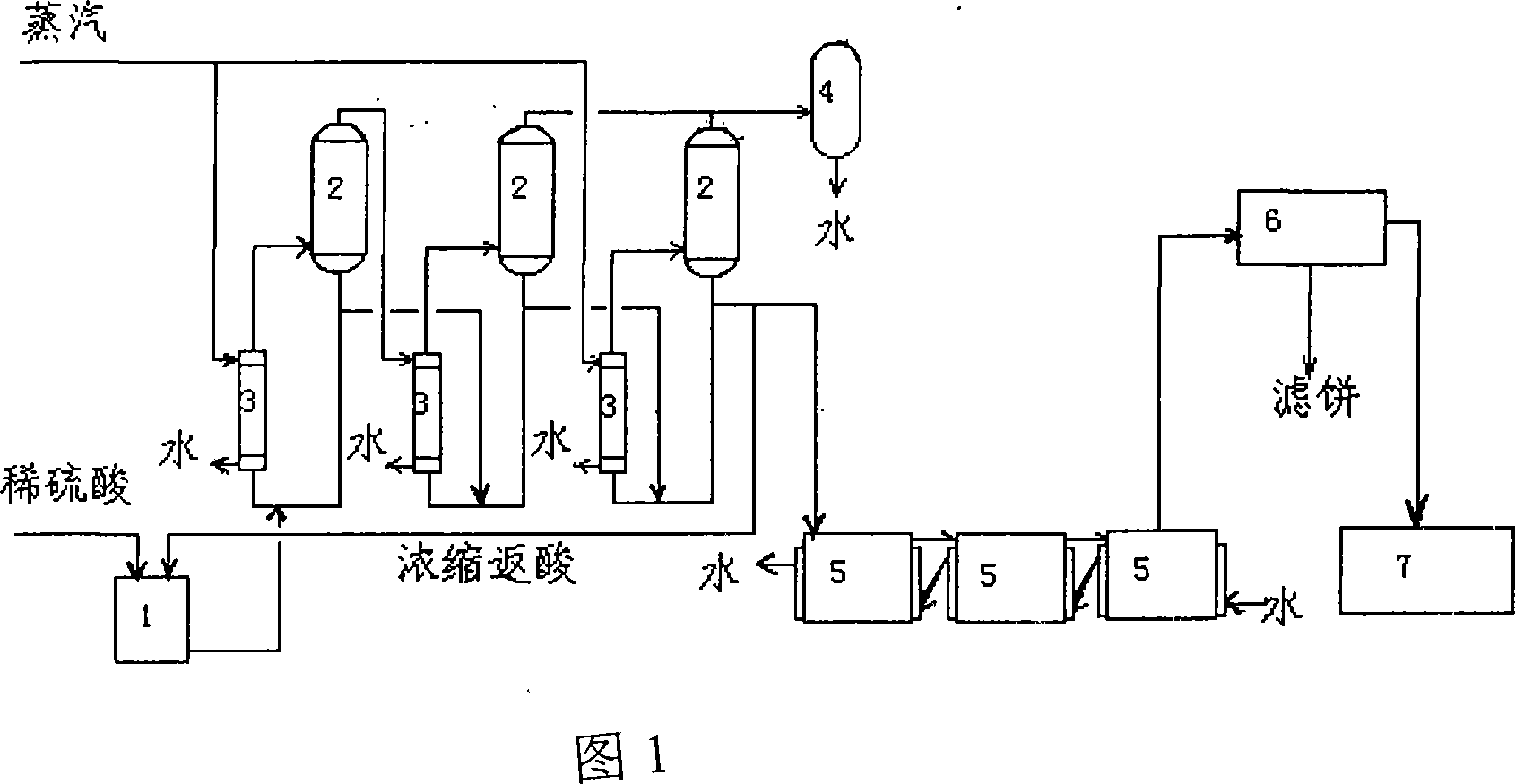

[0029] 22.2 tons of 23.5% titanium white dilute sulfuric acid per hour and 4.3 tons of 60% concentrated sulfuric acid per hour enter the acid mixing tank 1, and the mixed dilute sulfuric acid of 26.5 tons per hour with a concentration of 29.4% is pumped into the multi-effect Graphite tube heat exchanger 3 and multi-effect concentration evaporator 2 carry out evaporation and concentration. After the material is concentrated by multi-effect evaporation, 13.0 tons of sulfuric acid concentrated material with a concentration of 60% per hour are obtained, of which 4.3 tons are returned to the front acid mixing tank to mix acid, and 8.7 Tons enter the cooling and aging crystal growth tank 5 for cooling and aging crystal growth. The inlet temperature is 110° C., the outlet temperature is 50° C., and the residence time is 3 hours. Then it is se...

Embodiment 2

[0031] The composition of titanium white dilute sulfuric acid is as follows: dilute sulfuric acid density: 1320 (kg / cm 3 )

[0032] components

[0033]20.6 tons per hour of 22.26% titanium dioxide dilute sulfuric acid and 6.0 tons per hour of 70% concentrated sulfuric acid enter the acid mixing tank 1, and the mixed per hour 26.6 tons of 33.0% concentration of dilute sulfuric acid is sent to the multi-effect by the sulfuric acid pump Graphite tube heat exchanger 3 and multi-effect concentration evaporator 2 carry out evaporation and concentration. After the material is concentrated, 12.6 tons of sulfuric acid concentrated material with a concentration of 70% per hour are obtained, of which 6.0 tons are returned to the front acid mixing tank to mix acid, and 6.6 tons enter the cooling The aging crystal growth tank 5 carries out cooling and aging crystal growth, the inlet temperature is 115° C., the outlet temperature is 45° C., and the residence time is 4 hours. Then...

Embodiment 3

[0035] The composition of titanium white dilute sulfuric acid is as follows: dilute sulfuric acid density: 1320 (kg / cm 3 )

[0036] components

[0037] 15.53 tons per hour of 22.26% titanium dioxide dilute sulfuric acid and 3.0 tons per hour of 70% concentrated sulfuric acid enter the acid mixing tank 1, and the mixed 18.53 tons of 30.0% concentration of dilute sulfuric acid per hour are sent to the multi-effect by the sulfuric acid pump Graphite tube heat exchanger 3 and multi-effect concentration evaporator 2 carry out evaporation and concentration. After the material is concentrated, 8.96 tons of sulfuric acid concentrated material with a concentration of 62% per hour is obtained. The temperature was 120°C, the outlet temperature was 55°C, and the residence time was 3 hours. Then it is sent to the diaphragm filter press for pressure filtration to separate 6.46 tons of 70.2% concentrated sulfuric acid, 3.0 tons is returned to the front acid mixing tank to mix acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com