Method for co-production of white carbon black, aluminum oxide and kerogen by kerosene shale

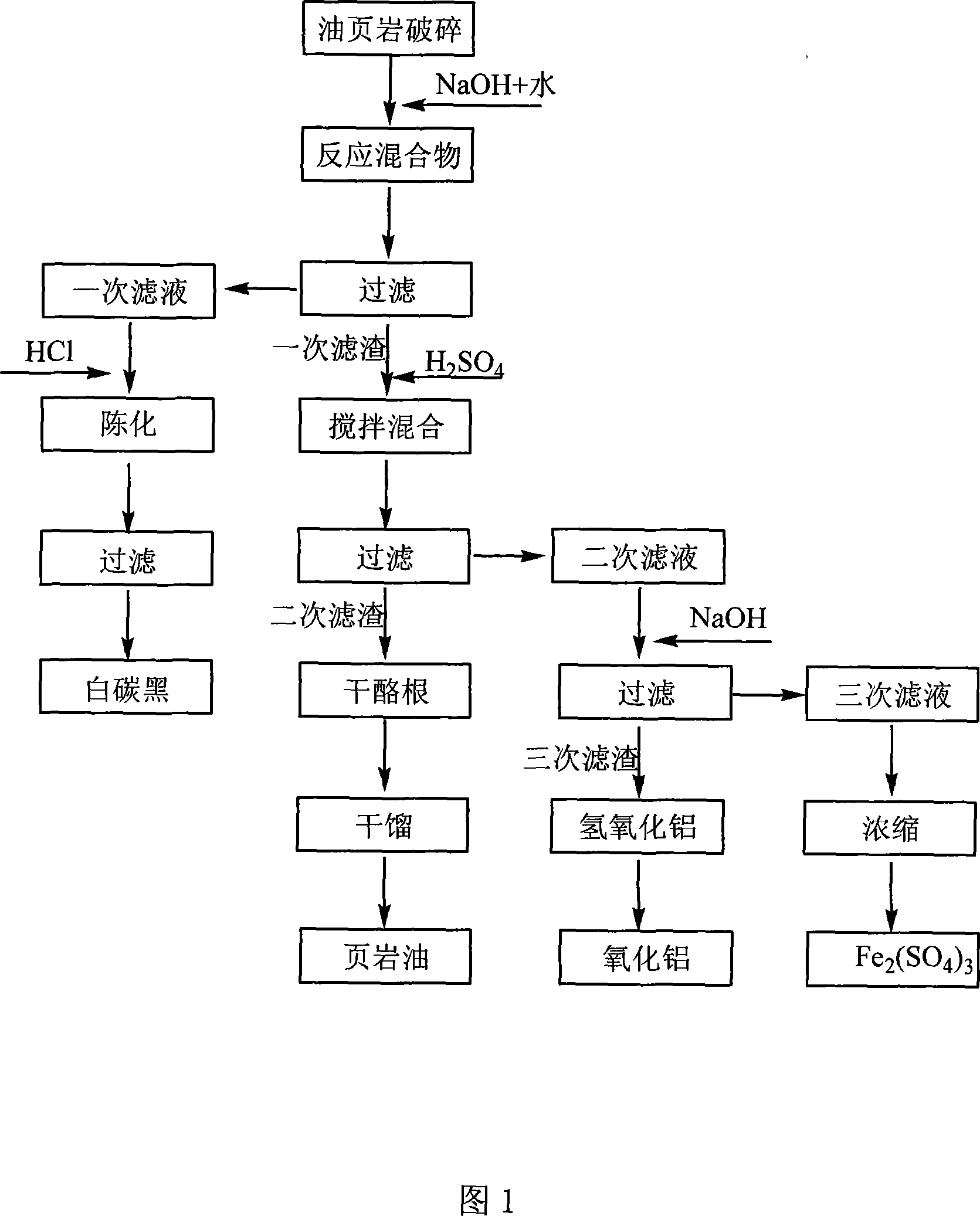

An oil shale and silica technology, which is applied in the field of co-producing silica, alumina and kerogen with oil shale, can solve the problems of low utilization rate of retorting furnace, low kerogen heat, polluting the environment, etc. Solve the effects of environmental pollution and land occupation, uniform particle distribution and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 15 grams of oil shale, particle size ≤ 0.124mm, oil shale contains 48.14% SiO 2 , 15.01% Al 2 o 3 , Fe 2 o 35.86%, kerogen content is 21.6%. Add oil shale and 10.0g NaOH into a 250mL three-necked flask, and continue to add 30.0mL H 2 O, raise the temperature to 100° C., and simultaneously start the electric stirrer for stirring, and continue the reaction for 8 hours. The reaction mixture was filtered to obtain a filtrate and a filter cake. One time, add 1.0g polymer dispersant ethanol to the filtrate. At room temperature, while stirring with a magnetic stirrer, slowly add hydrochloric acid to adjust the aging process of the pH value. When the pH is around 10, a white precipitate begins to appear. stop adding hydrochloric acid, continue aging and stirring for 2 hours, stop stirring, let stand overnight, filter, and the dry product is 7.2g of white carbon black, SiO 2 The content is 93.3%. The filtered liquid is used for the subsequent aging process of prepa...

Embodiment 2

[0023] Weigh 15 grams of oil shale, the particle size is 0.124mm~0.178mm, and the oil shale contains 48.14% SiO 2 For, 15.01% Al 2 o 3 , 5.86% Fe 2 o 3 , the kerogen content is 21.6%. and 10.0g NaOH were added to a 250mL three-necked flask, and 30.0mL H 2 O, raise the temperature to 100° C., and simultaneously start the electric stirrer for stirring, and continue the reaction for 8 hours. The reaction mixture was filtered to obtain a filtrate and a filter cake. Add 1.0g dispersant polyethylene glycol to the filtrate once, and at room temperature, while stirring with a magnetic stirrer, slowly add hydrochloric acid dropwise to adjust the aging process of the pH value. When the pH is around 10, a white precipitate begins to appear. stop adding hydrochloric acid, continue aging and stirring for 2 hours, stop stirring, let stand overnight, filter, wash 2 times with 2 times of water, and the dry product is 6.3g of white carbon black, SiO 2 The content is 94.5%. The filtered...

Embodiment 3

[0026] Weigh 15 grams of oil shale, the particle size is 0.25mm-0.42mm, and the oil shale contains 48.14% SiO 2 , 15.01% Al 2 o 3 , Fe 2 o 3 5.86%, kerogen content is 21.6%. and 10.0g NaOH were added to a 250mL three-necked flask, and continued to 50.0mL H 2 O, raise the temperature to 100° C., and simultaneously start the electric stirrer for stirring, and continue the reaction for 16 hours. The reaction mixture was filtered to obtain a filtrate and a filter cake. Add 1.0mL dispersant polyethylene glycol to the filtrate once, and at room temperature, while stirring with a magnetic stirrer, slowly add sulfuric acid dropwise to adjust the aging process of the pH value. When the pH is around 7.0, a white precipitate begins to appear. Stop adding hydrochloric acid, continue aging and stirring for 2 hours, stop stirring, let stand overnight, filter, and the dry product is 5.5g of white carbon black, SiO 2 The content is 92.4%. The filtered liquid is used for the subsequent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com