Treatment method of zinc-containing and iron-containing waste acid

A processing method and technology for iron powder, applied in the field of processing zinc-containing iron-containing waste acid, can solve the problems of difficulty in recycling, low recovery rate of zinc and iron, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

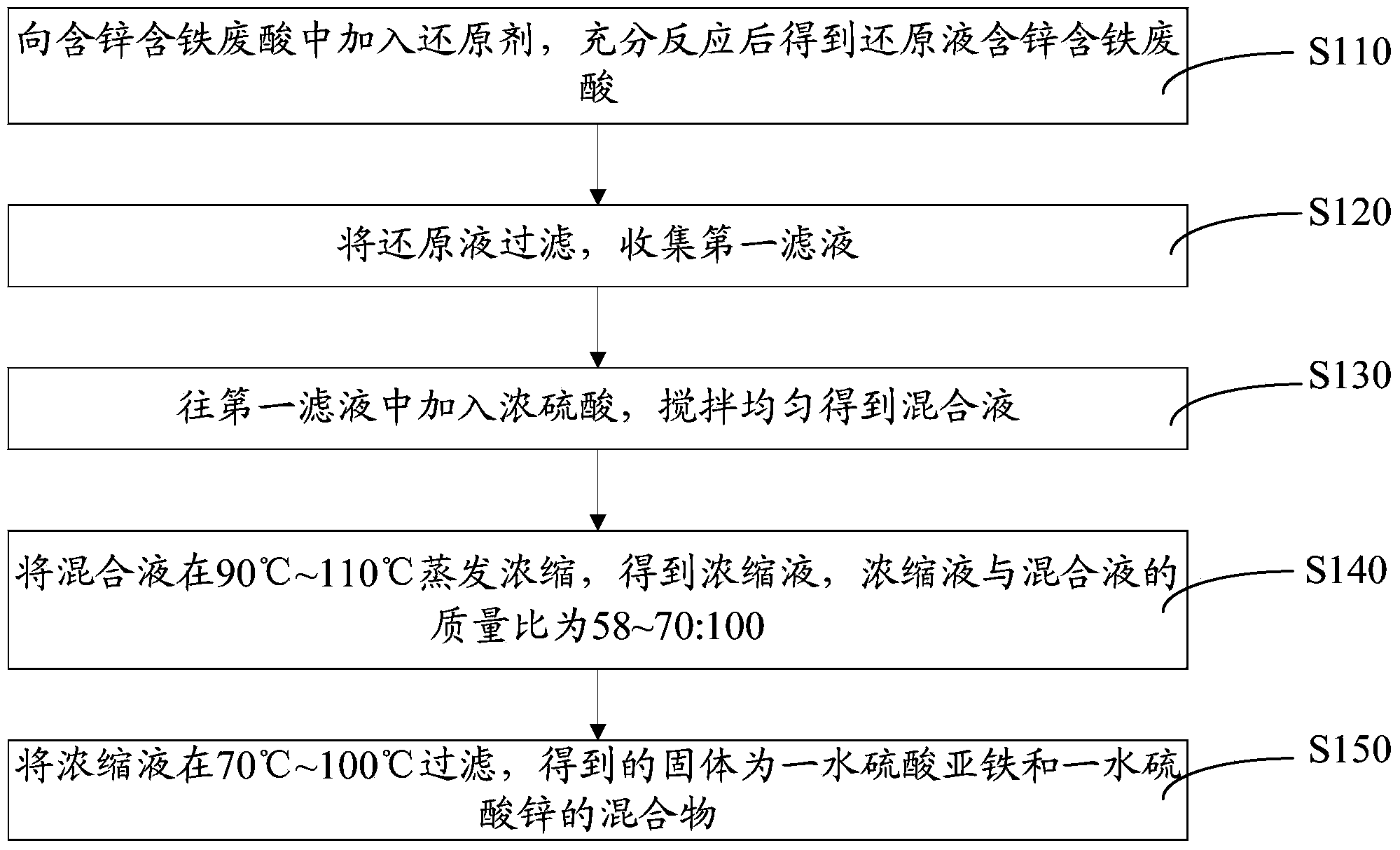

Method used

Image

Examples

Embodiment 1

[0071] Add 1kg of iron powder to 50kg of zinc-containing iron-containing waste acid and let it stand for 36 hours to obtain a reducing solution. The mass percentage of zinc ions in the reducing solution is 1.65%, the mass percentage of ferrous ions is 8.13%, and the mass percentage of hydrochloric acid is 0.55%.

[0072] The reducing liquid is subjected to pressure filtration treatment, and the first filtrate is collected.

[0073] Put the first filtrate into the evaporator, slowly add 7.5kg 98% concentrated sulfuric acid under stirring conditions, and obtain a mixed solution after stirring evenly.

[0074] The evaporator was evacuated, the circulating cooling water was turned on, the temperature of the evaporator was raised to 90°C, and the vacuum evaporation was concentrated for 1 hour to obtain a concentrated solution. The mass ratio of concentrated liquid to mixed liquid is 70:100. The concentrated liquid is centrifuged and filtered, and the solid obtained is a mixture of ferro...

Embodiment 2

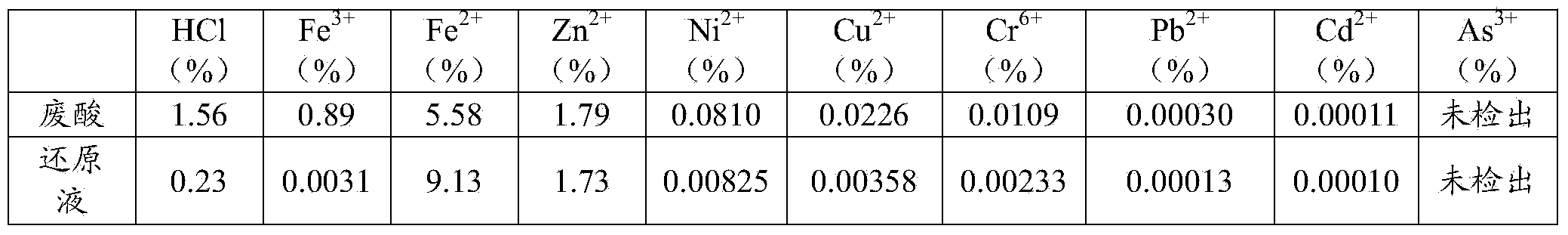

[0076] Add 2.5 kg of iron powder to 50 kg of zinc-containing and iron-containing waste acid, and let it stand for 24 hours to obtain a reducing solution. Table 3 shows the mass percentages of zinc ions, ferrous ions, and hydrochloric acid in the untreated zinc-containing iron-containing waste acid and the reducing solution.

[0077] table 3

[0078]

[0079] The reducing liquid is subjected to pressure filtration treatment, and the first filtrate is collected. Add the first filtrate to the evaporator, slowly add 15kg of 65% concentrated sulfuric acid under stirring conditions, and obtain a mixed solution after stirring evenly.

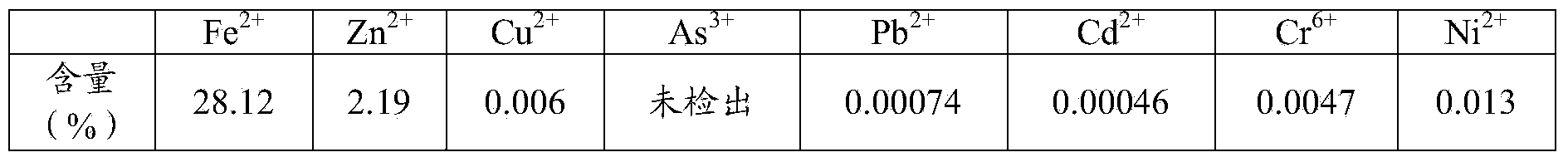

[0080] Apply a vacuum to maintain the pressure of the evaporator at -0.095MPa, turn on the circulating cooling water, raise the temperature of the evaporator to 95°C, and concentrate by vacuum evaporation for 1.5 hours to obtain a concentrated solution. The mass ratio of concentrated liquid to mixed liquid is 64:100. Centrifugal filtration of the concentra...

Embodiment 3

[0084] Add 2.5 kg of zinc powder to 50 kg of zinc-containing iron-containing waste acid, and let it stand for 12 hours to obtain a reducing solution. The reducing liquid is subjected to pressure filtration treatment, and the first filtrate is collected. Put the first filtrate into the evaporator, slowly add 7.5kg 98% concentrated sulfuric acid under stirring conditions, and obtain a mixed solution after stirring evenly.

[0085] Apply a vacuum to maintain the pressure of the evaporator at -0.095MPa, turn on the circulating cooling water, raise the evaporator to 100°C, and concentrate by vacuum evaporation for 1.5 hours to obtain a concentrated solution. The mass ratio of concentrated liquid to mixed liquid is 64:100. The concentrated solution is spray-dried to obtain a mixture of ferrous sulfate monohydrate and zinc sulfate monohydrate, wherein the mass percentage of ferrous ions is 23.5% and the mass percentage of zinc ions is 7.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com