Novel method for performing vacuum crystallization on ferrous sulfate from titanium liquid in titanium dioxide production process

A production process, ferrous sulfate technology, applied in the direction of ferric sulfate, solution crystallization, etc., can solve the problems of steam cooling effect reduction, water evaporation reduction, acidic water vapor mixing, etc., to achieve simple and easy equipment operation, reduce environmental pressure and , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

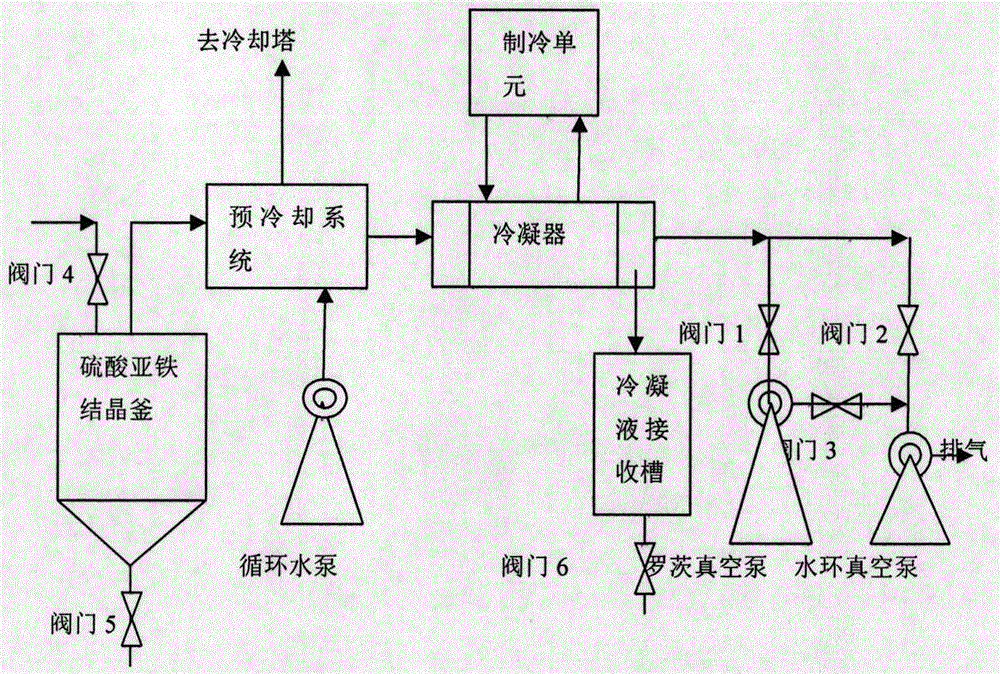

[0019] Embodiment 1: according to figure 2 The pre-cooling system in the complete set of equipment of the present invention is connected with the upper steam outlet of the ferrous sulfate crystallization kettle, and then the condensation system is connected with the pre-cooling system, and the vacuum equipment Roots vacuum pump and the water ring vacuum pump are pressed figure 2 The method is connected to the upper pipe of the condensate outlet of the condenser in the condensation system, and the valve 1 and the valve 3 are closed, thus forming the ferrous sulfate vacuum crystallization complete system equipment of the present invention which is condensed into liquid and combined with a single vacuum pump.

[0020] Open the valve 4, and dissolve the titanium liquid 35M produced by dissolving the ilmenite powder with sulfuric acid 3 Close valve 4 after being driven into the ferrous sulfate crystallization still of suitable volume. When the temperature of the titanium liquid ...

Embodiment 2

[0021] Embodiment 2: according to figure 2 The pre-cooling system in the complete set of equipment of the present invention is connected with the upper steam outlet of the ferrous sulfate crystallization kettle, and then the condensation system is connected with the pre-cooling system, and the vacuum equipment Roots vacuum pump and the water ring vacuum pump are pressed figure 2 The method is connected to the upper pipe of the condensate outlet of the condenser in the condensing system, closes the valve 2, opens the valve 1 and the valve 3, and thus forms the ferrous sulfate vacuum crystallization complete system equipment of the present invention which is condensed into liquid + double vacuum pump combination .

[0022] Open the valve 4, dissolve the titanium liquid 35M produced by dissolving the ilmenite with sulfuric acid 3 Put in a suitable volume of ferrous sulfate crystallization kettle and close valve 4. When the temperature of the titanium liquid in the kettle reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com