Method for synthesizing polymeric ferric sulphate

A technique of polymerizing ferric sulfate and its synthesis method, which is applied in the fields of ferric sulfate, flocculation/precipitation water/sewage treatment, etc. It can solve the problems of high cost and large amount of hydrogen peroxide, and achieve the effects of low cost, pollution avoidance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

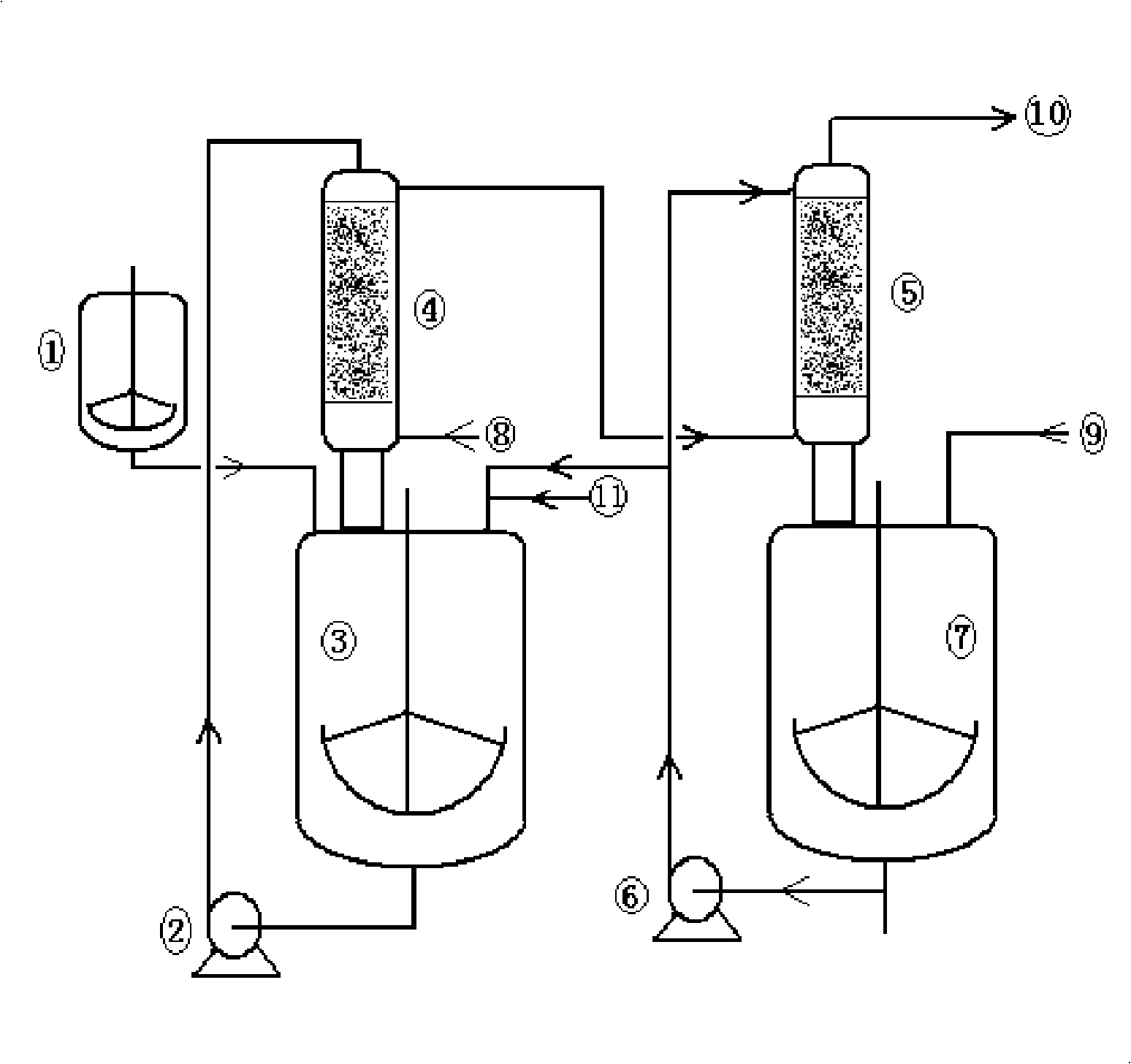

[0031] 2000 kilograms of solid industrial ferrous sulfate, 1000 kilograms of 20% sulfuric acid are added in the acid-resistant enamel reactor (3) from (11), and the speed control of stirring is 130 rev / min. Heating up, adding 100 kilograms of acid ferric nitrate in (1), feeding air from (8), the catalytic oxidation polymerization reaction is carried out in the temperature range of 75-105 ℃, and the reaction time is controlled at 2 hours, and the product that generates is deep Brown viscous polyferric sulfate.

Embodiment 2

[0033] 1900 kilograms of solid industrial ferrous sulfate, 1000 kilograms containing 18% ferrous sulfate 20% titanium white sulfate waste acid (11) are added in the acid-resistant enamel reactor (3), and the speed control of stirring is 130 revs / min. Heating up, adding 300 kilograms of acid ferric nitrate in (1), feeding air from (8), the catalytic oxidation polymerization reaction is carried out in the temperature range of 75-105 ℃, and the reaction time is controlled at 2 hours, and the product that generates is deep Brown viscous polyferric sulfate.

[0034] The nitric oxide produced by the reaction kettle (3) is oxidized into nitrogen dioxide by the blown air or oxygen-enriched air in the oxidation packing tower (4) on the top of the reaction kettle, and the generated nitrogen dioxide is mixed with the reaction kettle circulation pump (2) The conveyed material continues to react. The nitric oxide carried by the air in the discharge pipe enters the tail gas absorption pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com