SAPO-34 molecular sieve and synthesis method thereof

A SAPO-34, molecular sieve technology, applied in the field of SAPO molecular sieve, to achieve the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

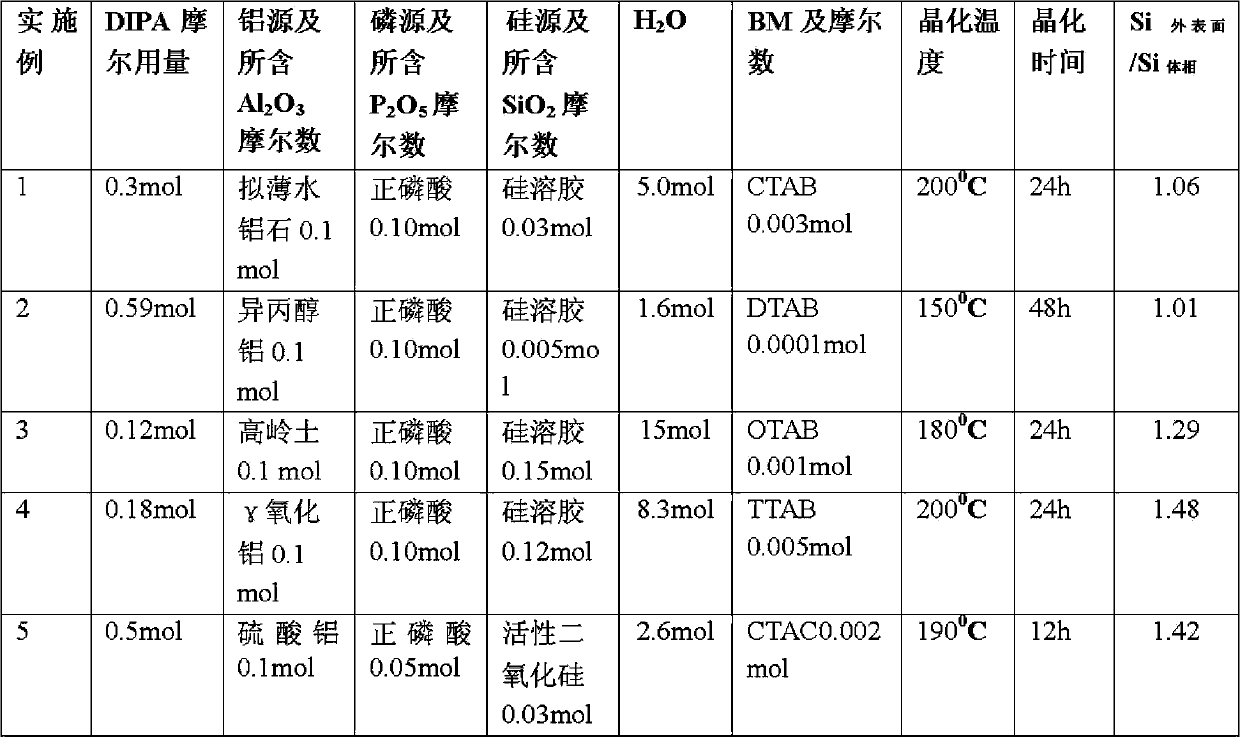

[0044] The dosage and crystallization conditions of ingredients are shown in Table 1. The specific batching process is as follows, 14.06g pseudo-boehmite (Al 2 o 3 Mass percent composition 72.5%) and 90g deionized water are mixed and stirred evenly, then 23.0g phosphoric acid (H 3 PO 4 mass percent content 85%) dropwise into, stir evenly, then add 6.4g silica sol (SiO 2 30% by mass percentage) and 1.09g cetyltrimethylammonium bromide (CTAB), after adding 30.4g diisopropylamine (DIPA for short, 99% by mass) to the mixture at last, the gel Transfer to a stainless steel reaction kettle. The molar ratio of each component in the synthesis system is 3.0DIPA:0.30SiO 2 : 1Al 2 o 3 : 1P 2 o 5 :0.03CTAB:50H 2 O.

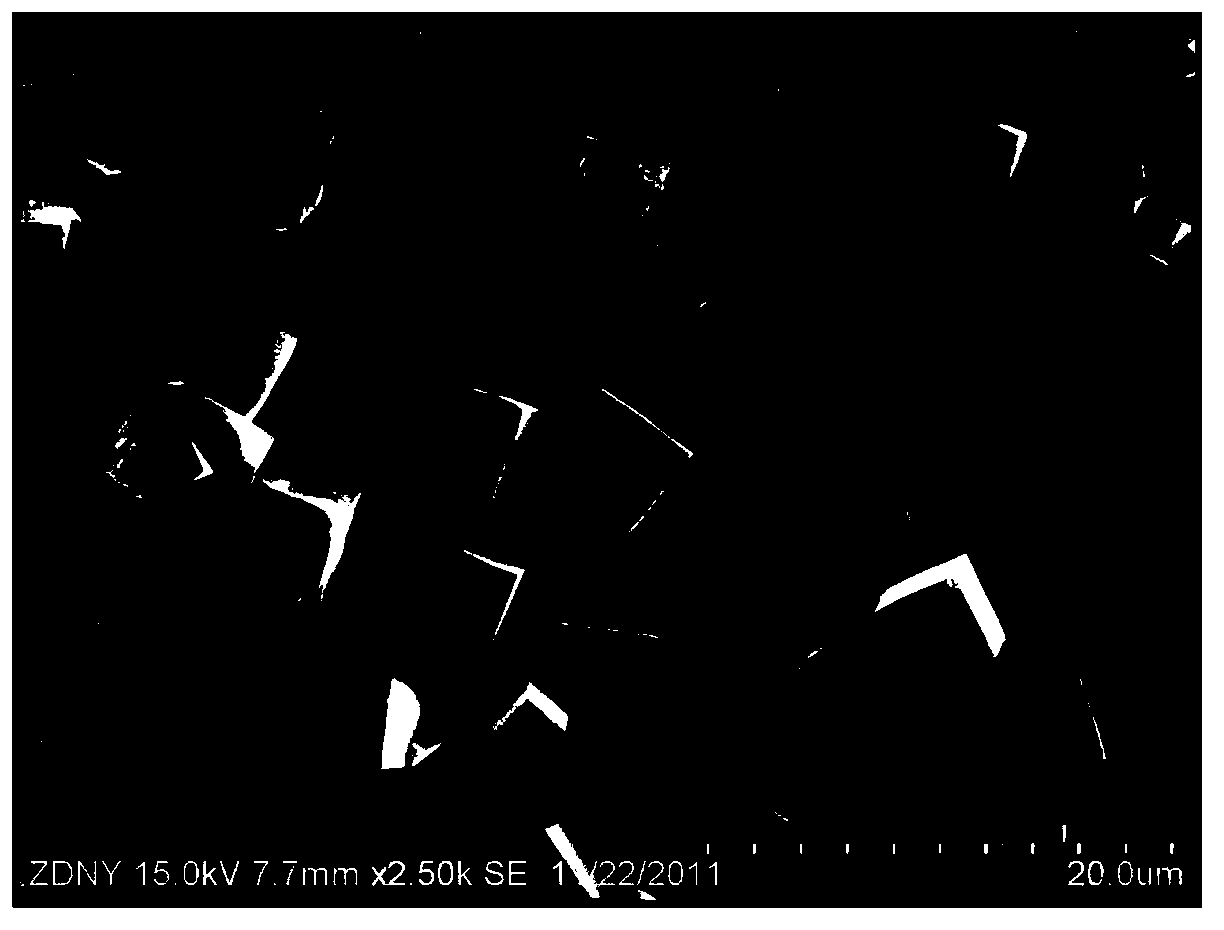

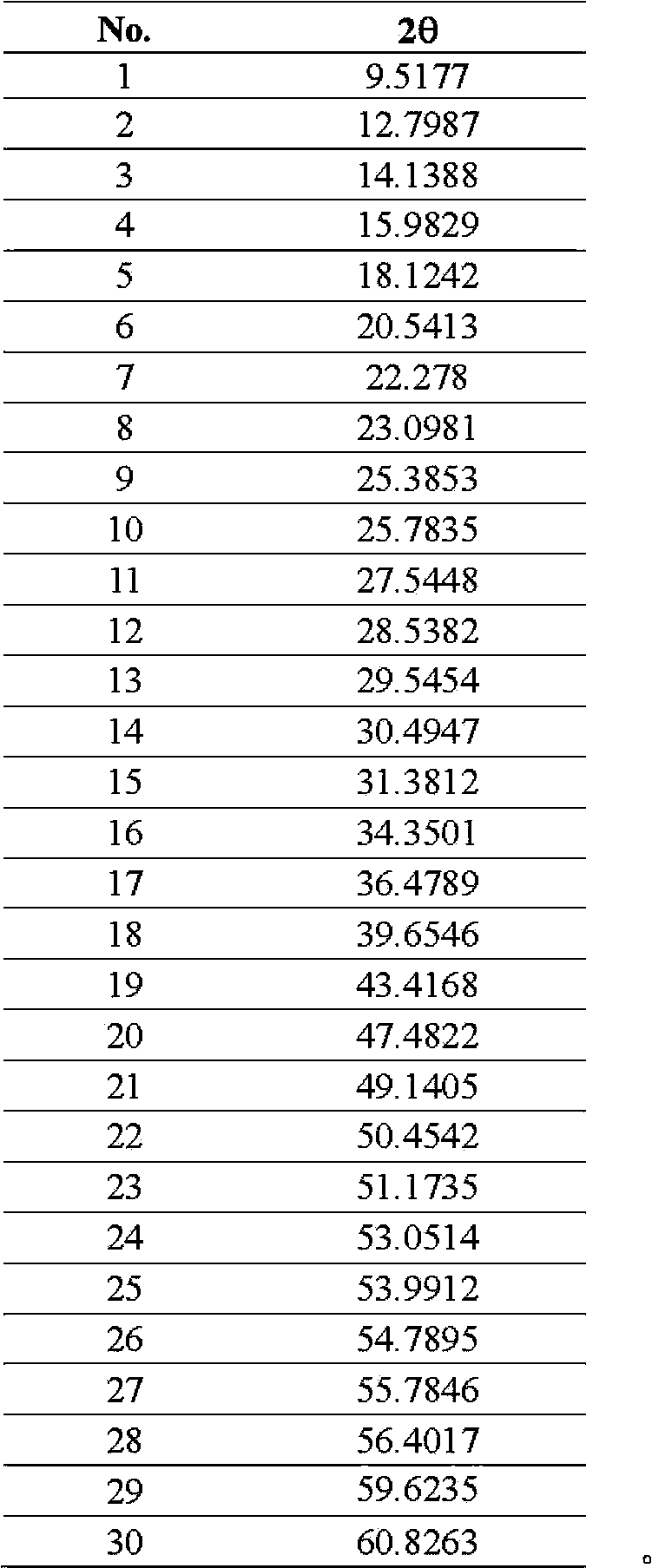

[0045] The synthesis kettle was heated to 200°C for dynamic crystallization for 24 hours. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100°C to obtain 27.6 g of the original powder. The sample was analyzed by XRD, and t...

Embodiment 2-17

[0055] The specific batching ratio and crystallization conditions are shown in Table 1, and the specific batching process is the same as in Example 1.

[0056] Synthetic samples were analyzed by XRD, and the data results were close to those in Table 2, that is, the peak positions and shapes were the same, and the relative peak intensity of the peaks fluctuated in the range of ±10% according to the change of the synthesis conditions, indicating that the synthetic products had the characteristics of the SAPO-34 structure.

[0057] The surface and bulk phase element compositions of the molecular sieve products were analyzed by XPS and XRF, and the ratio of the silicon content on the outer surface to the bulk phase silicon content is listed in Table 1.

[0058] CHN elemental analysis was carried out on the raw powder samples of Examples 2-17, which showed that the C / N molar ratio fluctuated at 6.0±0.05. The results of CHN elemental analysis and the composition of inorganic element...

Embodiment 18

[0061] The specific batching ratio and crystallization conditions are shown in Table 1, and the specific batching process is the same as in Example 1. Only the surfactant BM was replaced by the mixture of CTAB and OTAB, and the synthesis process was carried out statically. Synthetic samples were analyzed by XRD, and the results showed that the XRD results of the synthetic products were close to those in Table 2, that is, the peak positions and shapes were the same, and the relative peak intensities of each peak fluctuated in the range of ±10%, indicating that the synthetic products had the characteristics of the SAPO-34 structure.

[0062] The surface and bulk phase element compositions of the molecular sieve products were analyzed by XPS and XRF, and the ratio of the silicon content on the outer surface to the bulk phase silicon content is listed in Table 1.

[0063] The CHN elemental analysis of the raw powder sample of Example 18 showed that the C / N molar ratio was 5.95. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com