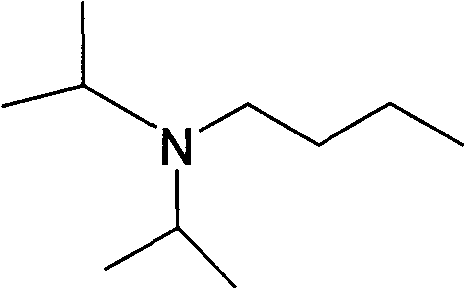

Synthesizing method of N,N-diisopropyl butylamine

A technology of propylbutylamine and synthesis method, which is applied in the field of N, can solve the problems of expensive raw materials, perishable, and many by-products, and achieve the effects of easy-to-obtain raw materials, low production costs, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

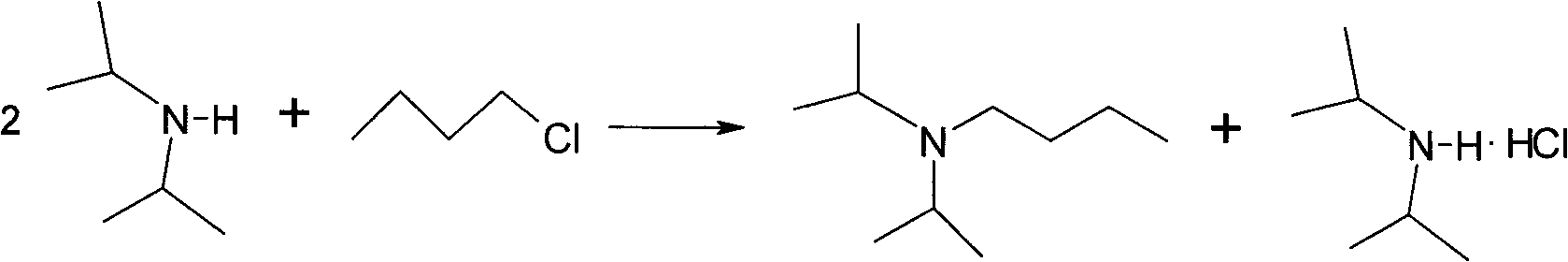

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, a kind of synthetic method of N, N-diisopropylbutylamine:

[0013] Add 84ml (0.6mol) of diisopropylamine and 32ml (0.3mol) of 1-chlorobutane into an autoclave with a stirring temperature measuring device, and close the lid of the kettle. The temperature was raised to 200°C within 1h, and the pressure was 1.36Mpa at this time. After maintaining the temperature and pressure for 4 hours, the reaction was terminated.

[0014] NaOH solution was added to the obtained reaction solution until the pH=13, the organic phase was separated and rectified, and the fraction at 162-163°C was collected to obtain 31.9 g of N,N-diisopropylbutylamine with a yield of 67.59%.

Embodiment 2

[0015] Embodiment 2, a kind of synthetic method of N, N-diisopropylbutylamine:

[0016] Add 127ml (0.9mol) of diisopropylamine and 32ml (0.3mol) of 1-chlorobutane into an autoclave with a stirring temperature measuring device, and close the lid of the kettle. The temperature was raised to 200°C within 1h, and the pressure was 1.36Mpa at this time. After maintaining the temperature and pressure for 4 hours, the reaction was terminated.

[0017] NaOH solution was added to the obtained reaction liquid until PH=13, the organic phase was separated and rectified, and the fraction at 162-163°C was collected to obtain 32.2 g of N,N-diisopropylbutylamine with a yield of 68.23%.

Embodiment 3

[0018] Embodiment 3, a kind of synthetic method of N, N-diisopropylbutylamine:

[0019] Add 127ml (0.9mol) of diisopropylamine and 32ml (0.3mol) of 1-chlorobutane into an autoclave with a stirring temperature measuring device, and close the lid of the kettle. The temperature was raised to 200°C within 1h, and the pressure was 1.36Mpa at this time. After maintaining the temperature and pressure for 8 hours, the reaction was terminated.

[0020] NaOH solution was added to the obtained reaction liquid until PH=13, the organic phase was separated and rectified, and the fraction at 162-163°C was collected to obtain 39.7 g of N,N-diisopropylbutylamine with a yield of 84.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com