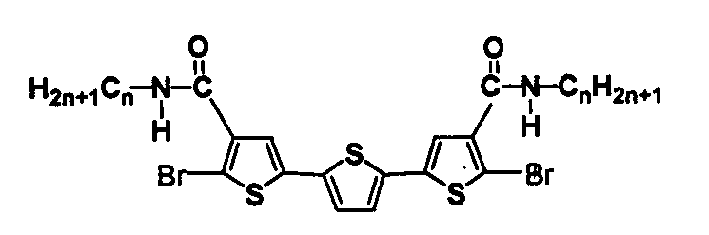

Liquid crystal compound contg. oligothiophene skeleton, preparing process thereof

A liquid crystal compound, oligothiophene technology, applied in chemical instruments and methods, liquid crystal materials, etc., can solve the problem of oligothiophene liquid crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The first step is at -78℃, N 2 A solution (30 ml) of DBr3T (5,5″-dibromo-2,2′:5′,2″-trithiophene, 2.0 g, 4.9 mmol) in tetrahydrofuran (THF) was added to diisopropylamine under protection Lithium (LDA, 19.6mmol) in tetrahydrofuran (THF, 20ml) solution, stirred for 1 hour;

[0018] In the second step, excess dry ice (CO 2 ), at -78°C, N 2 Under protection, continue to react for 3 hours, then warm up to room temperature, continue to react for 3 hours;

[0019] The third step is to add dilute hydrochloric acid to the reaction solution, continue to react for 5 hours, remove THF and water by filtration, wash with water, and dry;

[0020] The fourth step the above product (0.5g, 1.0mmol) was added to thionyl chloride (SOCl 2 , 0.24g, 2.0mmol) in 1,2-dichloroethane solution (80ml), reflux reaction for 5 hours, remove solvent;

[0021] The fifth step was to mix the above product with octadecylamine (0.5g, 1.9mmol) at 0°C under N 2 Under protection, react in the dichloromet...

Embodiment 2

[0023] The first step is at -78℃, N 2 A solution (40 ml) of DBr3T (5,5″-dibromo-2,2′:5′,2″-trithiophene, 3.0 g, 7.4 mmol) in tetrahydrofuran (THF) was added to diisopropylamine under protection Lithium (LDA, 29.6mmol) in tetrahydrofuran (THF, 30ml) solution, stirring reaction for 2 hours;

[0024] In the second step, excess dry ice (CO 2 ), at -78°C, N 2 Under protection, continue to react for 4 hours, then warm up to room temperature, continue to react for 4 hours;

[0025] The third step is to add dilute hydrochloric acid to the reaction solution, continue to react for 6 hours, filter to remove THF and water, wash with water, and dry;

[0026] The fourth step the above product (1.0g, 2.0mmol) was added to thionyl chloride (SOCl 2 , 0.48g, 4.0mmol) in 1,2-dichloroethane solution (100ml), reflux reaction for 7 hours, remove solvent;

[0027] The fifth step, the above product and hexadecylamine (0.9g, 3.7mmol) were mixed at 0°C under N 2 Under protection, react in dichlor...

Embodiment 3

[0029] The first step is at -78℃, N 2 A solution of DBr3T (5,5″-bisbromo-2,2′:5′,2″-trithiophene, 2.5 g, 6.1 mmol) in tetrahydrofuran (THF) (35 ml) was added to diisopropylamine under protection Lithium (LDA, 24.4mmol) in tetrahydrofuran (THF, 25ml) solution, stirring reaction for 3 hours;

[0030] In the second step, excess dry ice (CO 2 ), at -78°C, N 2 Under protection, continue to react for 5 hours, then warm up to room temperature, continue to react for 5 hours;

[0031] The third step is to add dilute hydrochloric acid to the reaction solution, continue to react for 8 hours, remove THF and water by filtration, wash with water, and dry;

[0032] The fourth step the above product (0.4g, 0.8mmol) was added to thionyl chloride (SOCl 2 , 0.19g, 1.6mmol) in 1,2-dichloroethane solution (60ml), reflux reaction for 8 hours, remove solvent;

[0033] The fifth step was to mix the above product with octaalkylamine (0.2g, 1.6mmol) at 0°C under N 2 Under protection, react in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com