Building glass heat-insulating coating and preparation method thereof

A technology of architectural glass and thermal insulation coatings, which is applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., and can solve problems such as poor mechanical resistance of coatings, impact on indoor human comfort, and thermal performance of windows , to achieve the effects of improving anti-aging performance, good thermal insulation effect, and good mechanical shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

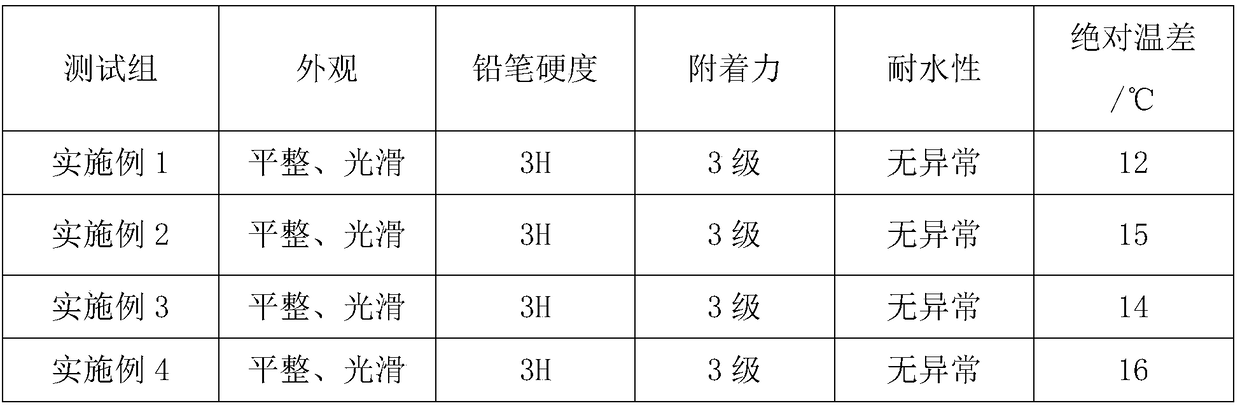

Examples

Embodiment 1

[0032] A kind of architectural glass thermal insulation paint, comprises the following raw materials in parts by weight:

[0033] 18 parts of acrylic emulsion, 10 parts of water-based polyurethane emulsion, 1 part of palm oil, 4 parts of nano-silica, 4 parts of nano-titanium dioxide, 2 parts of airgel, 4 parts of hollow glass microspheres, 2 parts of nano-silicon nitride, modified 2 parts of zinc oxide, 1 part of adhesion promoter, 0.2 part of defoamer, 0.6 part of dispersant and 0.6 part of film-forming aid.

[0034] The preparation method of modified zinc oxide is as follows:

[0035] (1) Zinc oxide and bismuth nitrate are mixed into a ball mill jar according to a mass ratio of 5:1, and the ball mill pulverizes raw materials;

[0036] (2) remove a certain amount of sodium hydroxide and add in the ball mill jar in step (1), the consumption of sodium hydroxide is 3.1 times of the molar number of bismuth nitrate consumption, and adds deionized water, the consumption of water i...

Embodiment 2

[0049] A kind of architectural glass thermal insulation paint, comprises the following raw materials in parts by weight:

[0050] 24 parts of acrylic emulsion, 16 parts of water-based polyurethane emulsion, 4 parts of palm oil, 7 parts of nano-silica, 7 parts of nano-titanium dioxide, 5 parts of airgel, 7 parts of hollow glass microspheres, 5 parts of nano-silicon nitride, modified 5 parts of zinc oxide, 3 parts of adhesion promoter, 0.6 parts of defoamer, 1.2 parts of dispersant and 1.2 parts of film-forming aid.

[0051] The preparation method of modified zinc oxide is as follows:

[0052] (1) Zinc oxide and bismuth nitrate are mixed into a ball mill jar according to a mass ratio of 5:1, and the ball mill pulverizes raw materials;

[0053] (2) remove a certain amount of sodium hydroxide and add in the ball mill jar in step (1), the consumption of sodium hydroxide is 3.2 times of the bismuth nitrate consumption molar number, and adds deionized water, the consumption of water...

Embodiment 3

[0066] A kind of architectural glass thermal insulation paint, comprises the following raw materials in parts by weight:

[0067] 20 parts of acrylic emulsion, 12 parts of water-based polyurethane emulsion, 2 parts of palm oil, 5 parts of nano-silica, 5 parts of nano-titanium dioxide, 3 parts of airgel, 5 parts of hollow glass microspheres, 3 parts of nano-silicon nitride, modified 3 parts of zinc oxide, 1.5 parts of adhesion promoter, 0.3 parts of defoamer, 0.8 parts of dispersant and 0.8 parts of film-forming aid.

[0068] The preparation method of modified zinc oxide is as follows:

[0069] (1) Zinc oxide and bismuth nitrate are mixed into a ball mill jar according to a mass ratio of 5:1, and the ball mill pulverizes raw materials;

[0070] (2) remove a certain amount of sodium hydroxide and add in the ball mill jar in step (1), the consumption of sodium hydroxide is 3.1 times of the molar number of bismuth nitrate consumption, and adds deionized water, the consumption of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com