Porous polyether-ether-ketone-based coating material and preparation method thereof

A technology of polyether ether ketone and coating materials, which is applied in the fields of coating, medical science, tissue regeneration, etc. It can solve the problems of low bonding strength between coating and substrate, difficult preparation process, poor stability, etc., and avoid thermal degradation , The preparation process is simple and practical, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

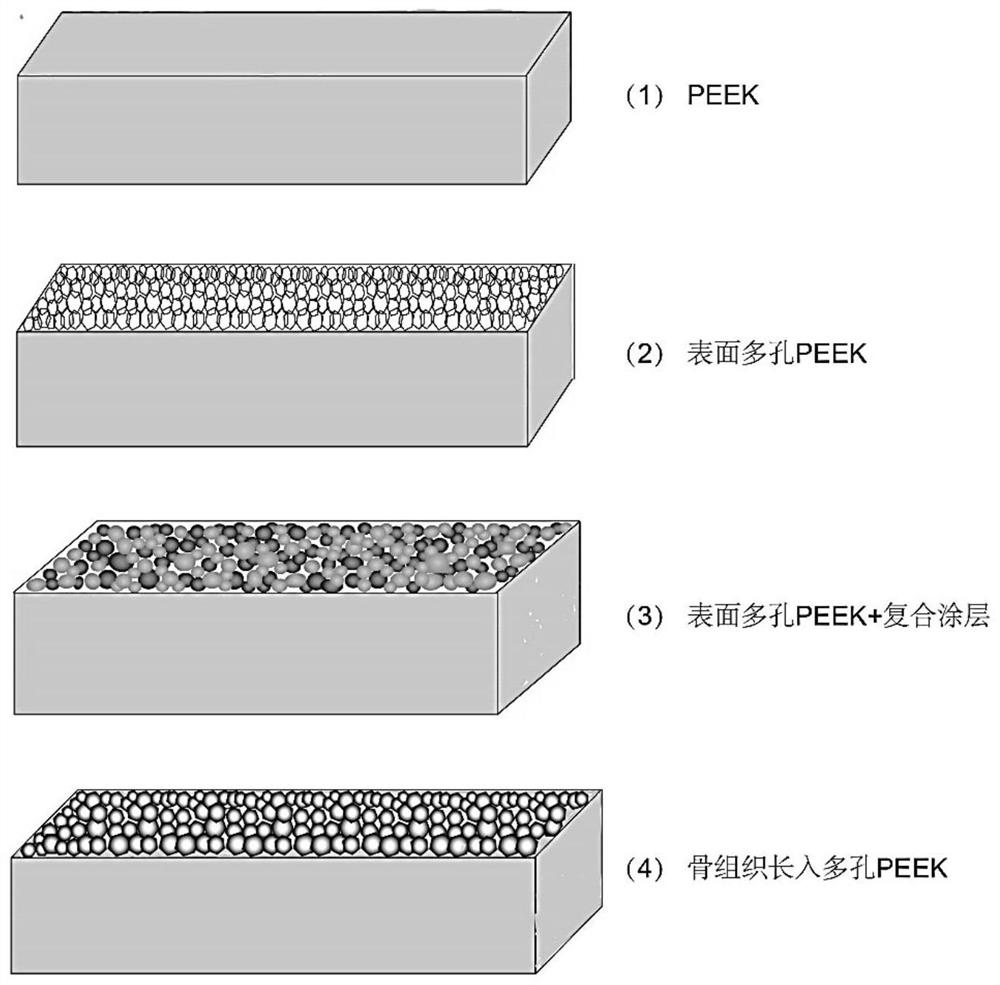

[0035] as attached figure 1 Shown, the present invention provides a kind of preparation method of porous polyetheretherketone based coating material, comprises the following steps:

[0036] Step 1. Treating the surface of the polyetheretherketone to form a porous structure on the surface of the polyetheretherketone to obtain polyetheretherketone with a porous surface.

[0037] Among them, the process of treating the surface of polyetheretherketone is specifically:

[0038] Soak polyether ether ketone in concentrated sulfuric acid for 4-6 minutes, then take out the soaked polyether ether ketone, rinse to remove residual sulfuric acid, and dry to obtain polyether ether ketone with a porous surface; When washing polyetheretherketone, first use distilled water to wash repeatedly 3-5 times; then use acetone to wash in an ultrasonic vibration environment to remove residual sulfuric acid; use distilled water to wash repeatedly to remove residual acetone.

[0039] Step 2. Using cold...

Embodiment 1

[0047] Embodiment 1 provides a porous polyether ether ketone-based coating material and a preparation method thereof, comprising the following steps:

[0048] Step 1. Place polyether ether ketone in concentrated sulfuric acid, magnetic stirring and soaking for 5 minutes; then take out the soaked polyether ether ketone, and rinse the soaked polyether ether ketone; washing process: first use distilled water to rinse repeatedly for 3- 5 times; then in an ultrasonic vibration environment, use acetone to rinse for 10 minutes to remove residual sulfuric acid; use distilled water to rinse repeatedly for 3-5 times, each time for 10 minutes to remove residual acetone; after drying, obtain polyetherether with a porous structure surface ketone.

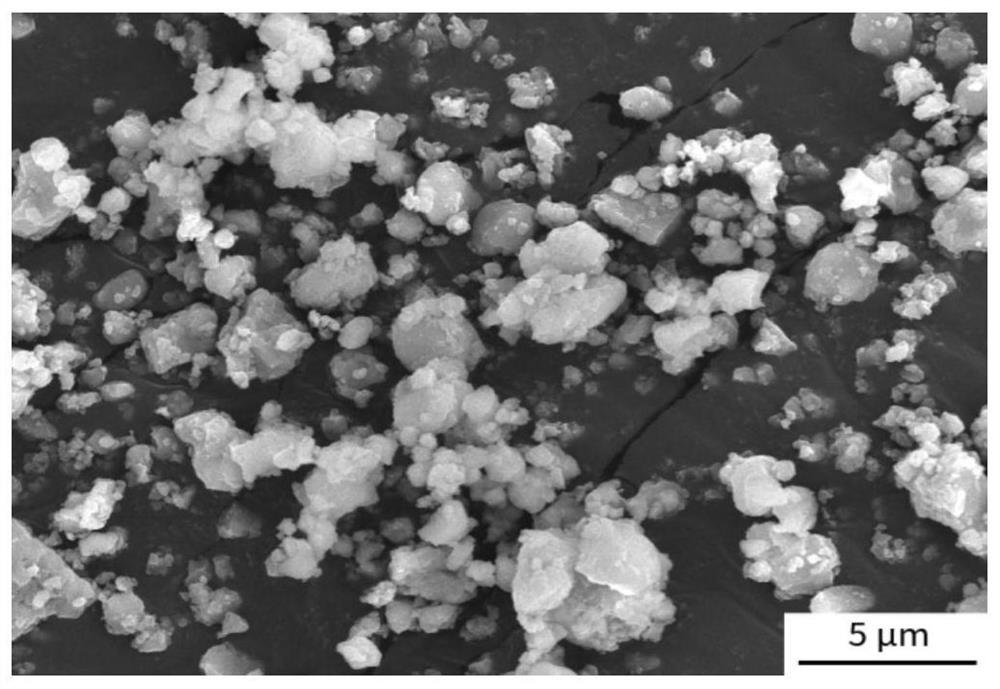

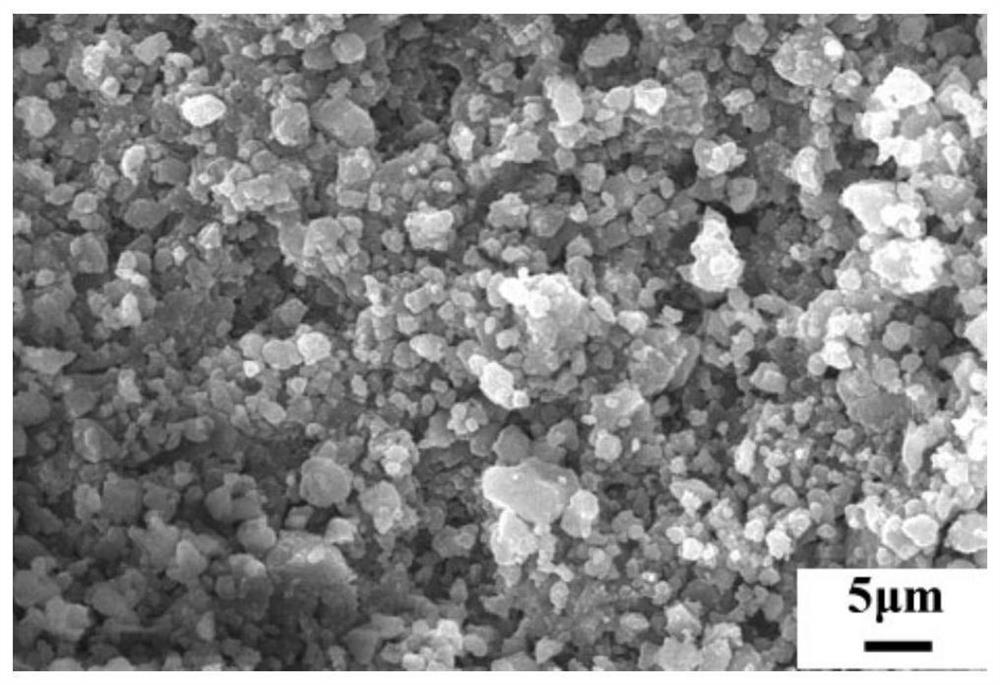

[0049] Step 2. Using vacuum cold spraying technology, the degradable material powder is deposited on the surface of the porous structure of polyetheretherketone to obtain the porous polyether ether ketone-based coating material; wherein the degr...

Embodiment 2

[0053] Embodiment 2 provides a porous polyetheretherketone-based coating material and a preparation method thereof, comprising the following steps:

[0054] Step 1. Place polyetheretherketone in concentrated sulfuric acid, magnetically stir and soak for 4 minutes; then take out the soaked polyether ether ketone, and rinse the soaked polyetheretherketone; first, rinse repeatedly with distilled water for 3-5 times; Then, in an ultrasonic vibration environment, wash with acetone for 10 minutes to remove residual sulfuric acid; wash with distilled water repeatedly for 3-5 times, each time for 10 minutes, to remove residual acetone; after drying, polyether ether ketone with a porous surface is obtained.

[0055] Step 2. Using vacuum cold spraying technology, the degradable material powder is deposited on the surface of the porous structure of polyetheretherketone to obtain the porous polyether ether ketone-based coating material; wherein the degradable material powder is calcium sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com