Antiskid powder coating and online coating method thereof

A powder coating, anti-skid technology, applied in powder coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc., can solve the problem of not finding effective technical information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A non-slip powder coating comprising the following raw materials in parts by weight:

[0028] 55 parts of phenolic modified epoxy resin, the softening point of the phenolic modified epoxy resin is 88-98℃, EPOXY RESIN KD-211H from Guodu Chemical Co., Ltd. Its epoxy equivalent range is 450-550g / eq, at 150 Its viscosity at ℃ is not higher than 40,000;

[0029] 15 parts of phenolic curing agent, V-209 from Shaanxi Jinchen Chemical Co., Ltd., with a hydroxyl equivalent range of 180-250g / eq;

[0030] 1 part of cellulose acetate, from EASTMAN: CAB-551-0.2;

[0031] For 29 parts of pigments and fillers, conventional pigments and fillers in the prior art can be used.

[0032] Preferably, in this embodiment, the method for preparing the powder coating as described above in this embodiment includes the following operations:

[0033] The phenolic modified epoxy resin, phenolic curing agent, cellulose acetate and pigments are pre-mixed, melt-extruded, and powdered to obtain powder ...

Embodiment 2

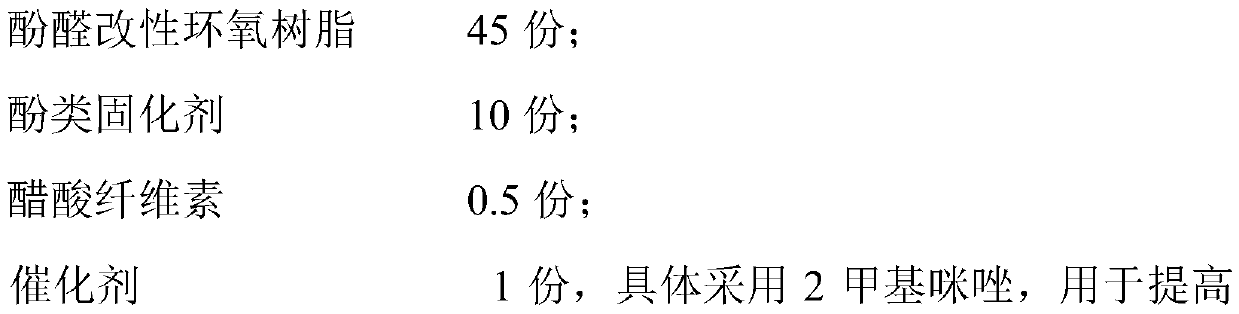

[0035] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as that of embodiment 1, the difference is that this embodiment 2 proposes a non-slip powder coating, including the following raw materials by weight:

[0036]

[0037] Crosslink curing reaction speed;

[0038] 1 part of degassing agent;

[0039] Pigment and filler 42.5 parts.

Embodiment 3

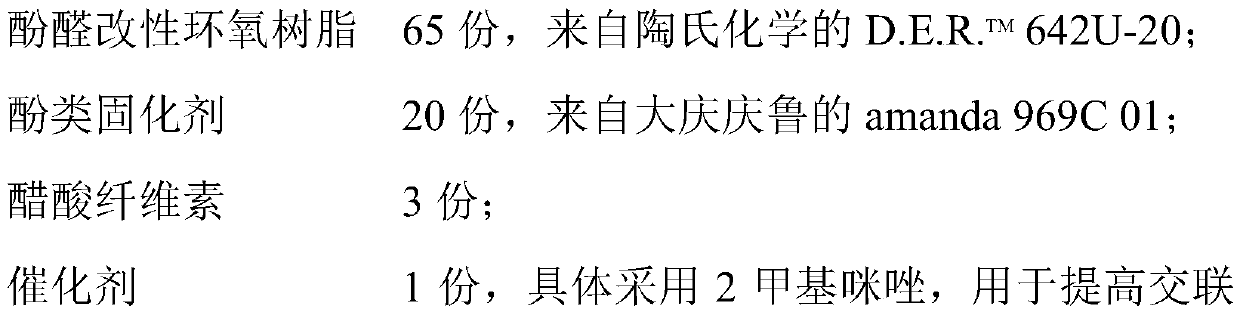

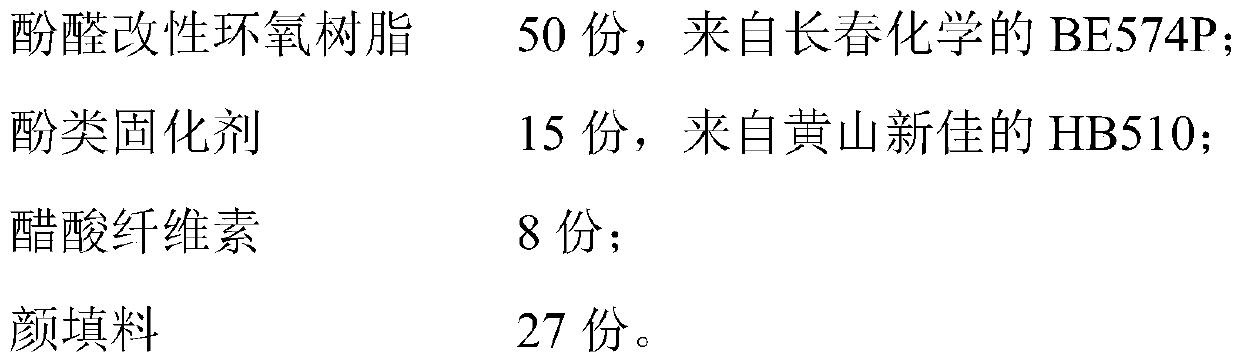

[0040] Embodiment 3: The remaining technical solutions of this embodiment 3 are the same as those of embodiment 1, except that this embodiment 3 proposes a non-slip powder coating, including the following raw materials in parts by weight:

[0041]

[0042] Curing reaction speed;

[0043] 1.5 parts of degassing agent;

[0044] Pigment and filler 9.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Hydroxyl equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com