Waterborne epoxy self-leveling anti-scratch floor paint and preparation process thereof

A technology of water-based epoxy and floor coatings, applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of fire hazards, discharge into the atmosphere, environmental pollution, etc., and achieve the elimination of fire hazards, coatings, etc. Strong adhesion and good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

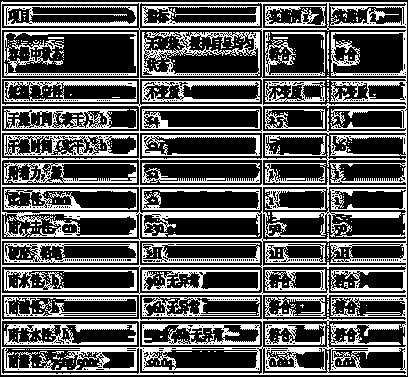

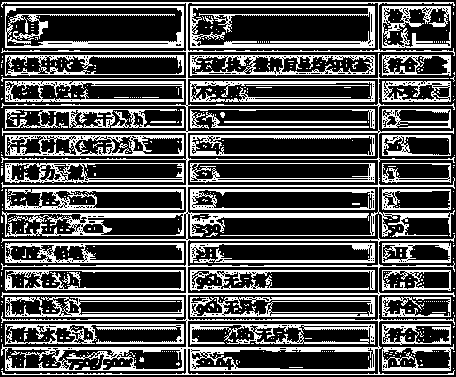

Embodiment 1

[0015] Embodiment 1: A kind of water-based epoxy self-leveling anti-scratch floor paint and its preparation process involved in the present invention are characterized in that it is formulated according to the mass fraction ratio of its raw materials: A component: water-based epoxy resin 80 parts, reactive diluent 20 parts; component B: 20 parts of water-based epoxy curing agent, 27 parts of deionized water, 0.2 parts of RS610 wetting and dispersing agent, 0.3 parts of DF681F defoamer, 0.6 parts of anti-scratch additive, 0.2 parts of A401 alkali swelling thickener, 4 parts of titanium dioxide, 2 parts of BGS phthalocyanine blue, 1 part of 801 strontium chrome yellow, 10 parts of light calcium carbonate, 20 parts of precipitated barium sulfate, 3 parts of anti-scratch agent, superfine 12 parts of talcum powder.

Embodiment 2

[0016] Embodiment 2: A kind of water-based epoxy self-leveling anti-scratch floor paint and its preparation process involved in the present invention are characterized in that it is formulated according to the mass fraction ratio of its raw materials: A component: water-based epoxy resin 80 parts, 20 parts of reactive diluent; component B: 25 parts of water-based epoxy curing agent, 22 parts of deionized water, 0.2 part of RS610 wetting and dispersing agent, 0.3 part of DF681F defoamer, 0.6 part of anti-scratch additive, 0.15 parts of A401 alkali swelling thickener, 5 parts of titanium dioxide, 2.5 parts of BGS phthalocyanine blue, 1.5 parts of 801 strontium chrome yellow, 10 parts of light calcium carbonate, 20 parts of precipitated barium sulfate, 3 parts of anti-scratch agent, superfine 10 parts of talcum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com