Water-based paint and preparation and application methods thereof

A water-based paint and water-based technology, applied in the field of modified paint, can solve the problems of high cost, limitation, and high energy consumption of spraying equipment, and achieve good thermal stability and gloss, suitable for large-scale production, and uniform dispersion of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

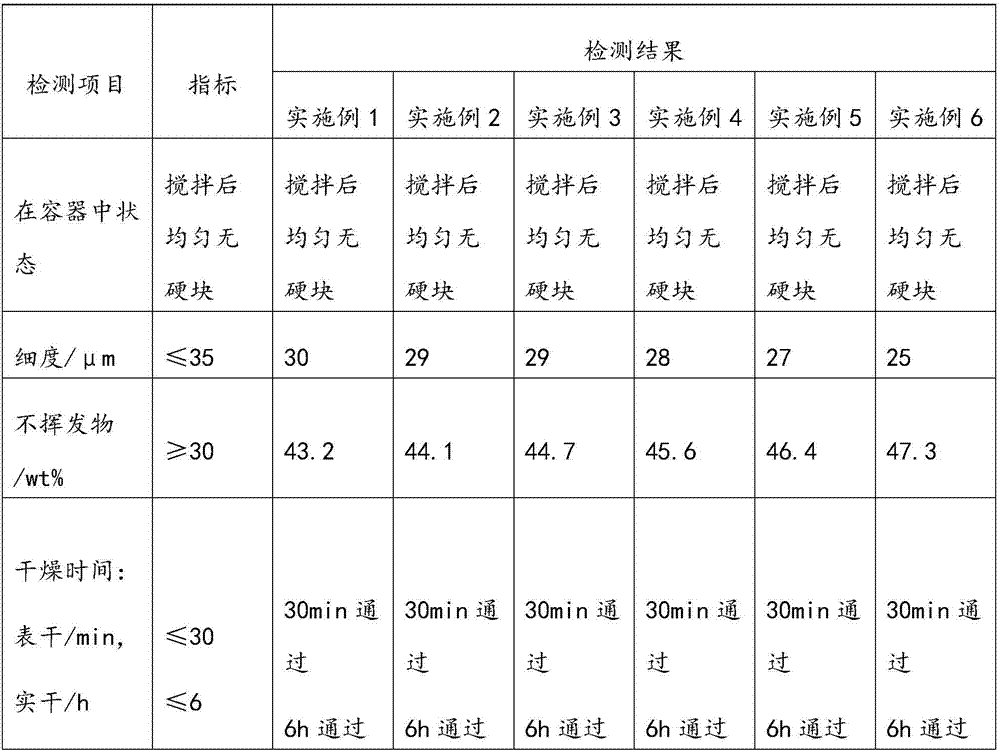

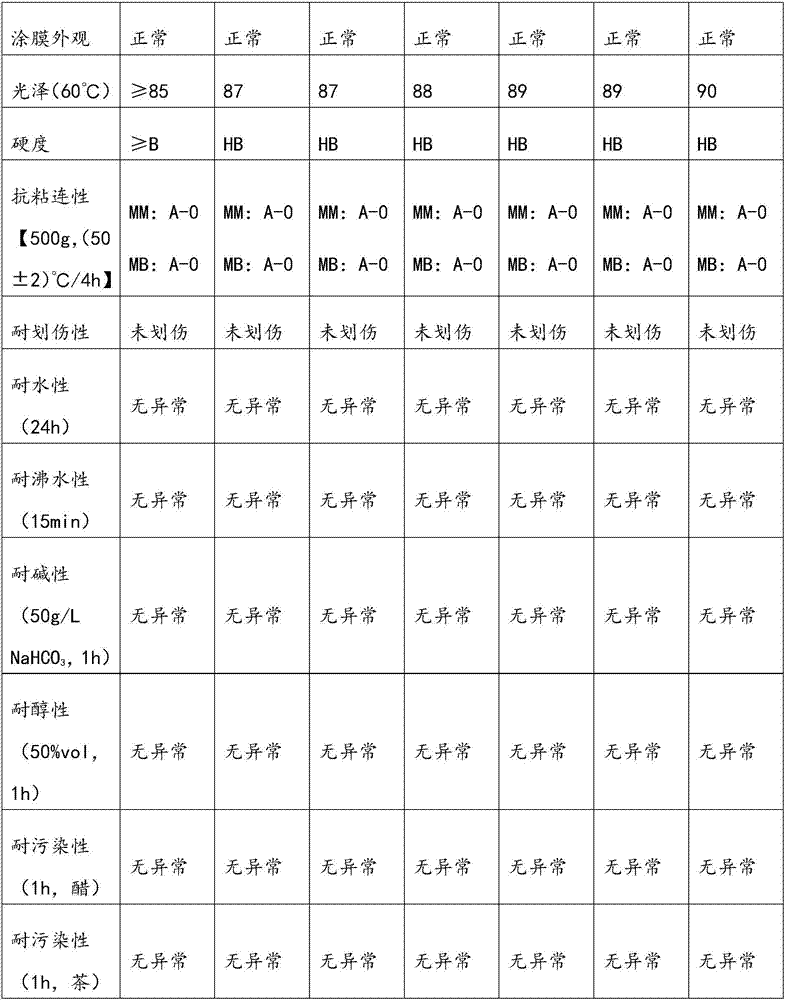

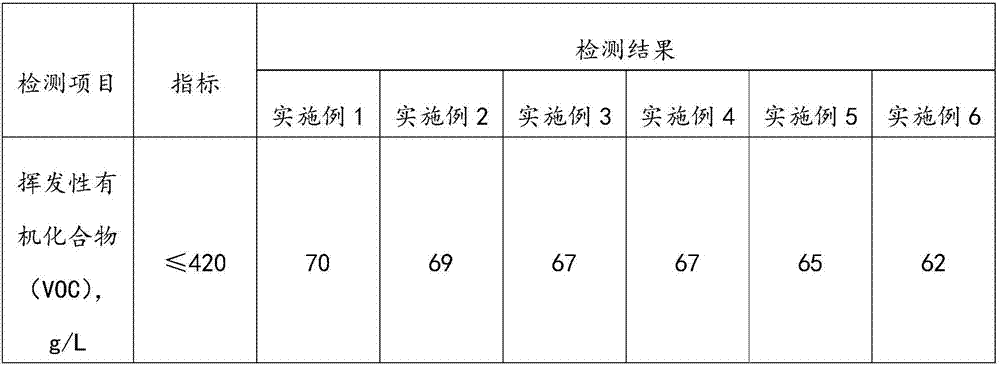

Examples

preparation example Construction

[0061] In the preparation method of the above water-based paint, all raw materials are fully mixed in proportion to obtain a water-based paint.

[0062] The preparation method of the water-based paint of the invention has simple process and is suitable for large-scale production.

[0063] Preferably, pre-mix the water-based fluorocarbon resin and polyethylene wax slurry. After confirming that the dispersion is uniform and free of particles, add water-based polyurethane resin, water-based silicone-modified polyurethane dispersion and silicone resin, and mix; then add water-based acrylic resin It is further mixed with water-based silicone modified acrylic resin to obtain a water-based paint.

[0064] Preferably, pre-mix the water-based fluorocarbon resin and polyethylene wax slurry. After confirming that the dispersion is uniform and free of particles, add water-based polyurethane resin, water-based silicone-modified polyurethane dispersion and silicone resin, and mix; then add ...

Embodiment 1

[0088] A preparation method of water-based paint, comprising:

[0089] Take 15kg of water-based fluorocarbon resin and 5kg of polytetrafluoroethylene-modified polyethylene wax slurry, stir and mix for 10min;

[0090] After confirming that the dispersion is uniform and free of particles, add 20kg of water-based polyurethane resin, 10kg of water-based silicone-modified polyurethane dispersion and 3kg of silicone resin (5592), and stir and mix for 10 minutes;

[0091] Add 10kg of water-based acrylic resin (9052) and 20kg of water-based silicone-modified acrylic resin, and stir and mix for 10 minutes;

[0092] Finally, 5 kg of transparent color essence (yellow shade) was added, and stirred and mixed for 10 minutes to obtain a water-based paint.

Embodiment 2

[0094] A preparation method of water-based paint, comprising:

[0095] Take 35kg of water-based fluorocarbon resin and 15kg of polytetrafluoroethylene-modified polyethylene wax slurry, stir and mix for 20min;

[0096] After confirming that the dispersion is uniform and free of particles, add 30kg of water-based polyurethane resin, 20kg of water-based silicone-modified polyurethane dispersion and 5kg of silicone resin (5593), and stir and mix for 20 minutes;

[0097] Add 30 kg of water-based acrylic resin (125) and 30 kg of water-based silicone-modified acrylic resin, and stir and mix for 20 minutes;

[0098] Finally, 8 kg of nano-color paste (CSE401GW), 0.5 kg of film-forming agent, 1.5 kg of defoamer (A10), 1.5 kg of leveling agent, and 0.5 kg of preservative were added, and stirred and mixed for 20 minutes to obtain a water-based paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com