Hydrocarbon-resistant outdoor thick fireproofing coating for steel structures

A fire retardant coating, thick coating technology, applied in fire retardant coatings, anti-corrosion coatings, coatings and other directions, can solve the problems of not being able to prevent hydrocarbon fires, the coating is not water-resistant, not moisture-proof, etc., to achieve excellent fire-resistant and anti-corrosion performance, The effect of strong coating adhesion and low smoke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

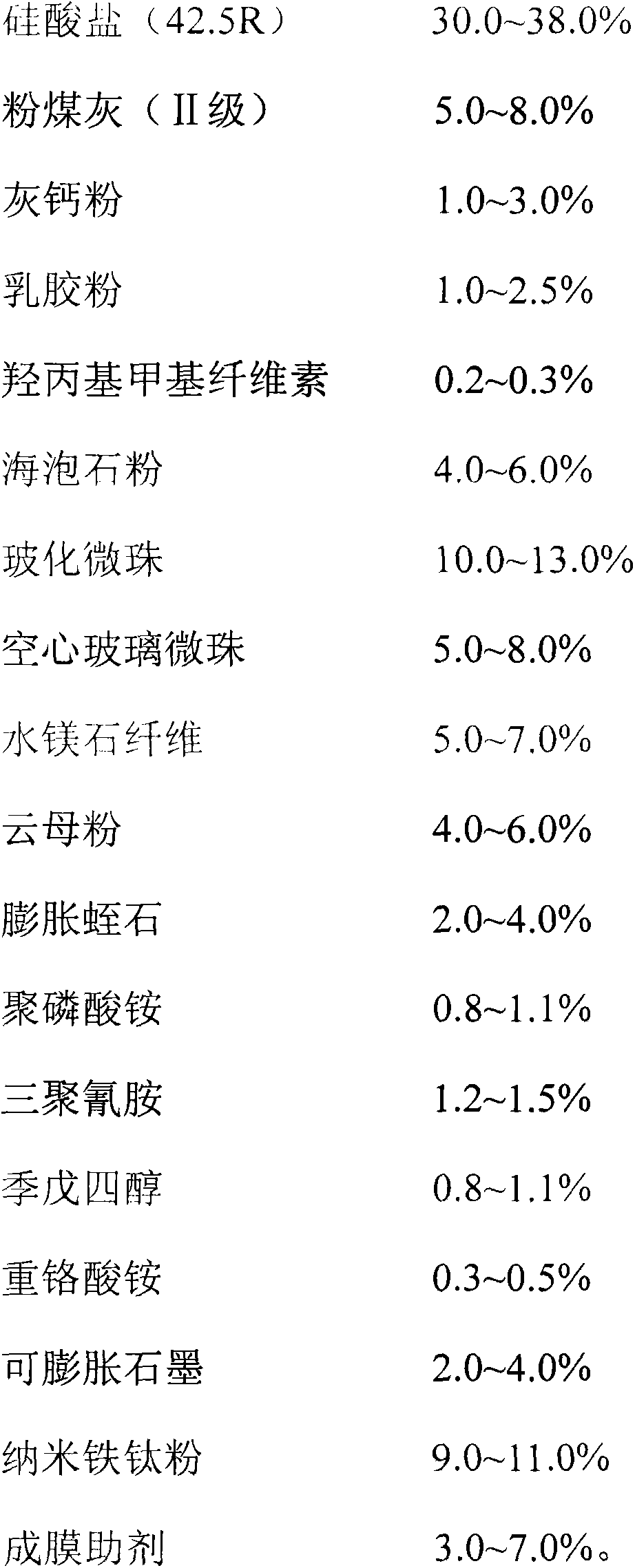

[0022] Hydrocarbon-resistant outdoor thick-coated steel structure fireproof coatings, the ratio of raw materials is calculated by weight percentage:

[0023]

[0024]

Embodiment 2

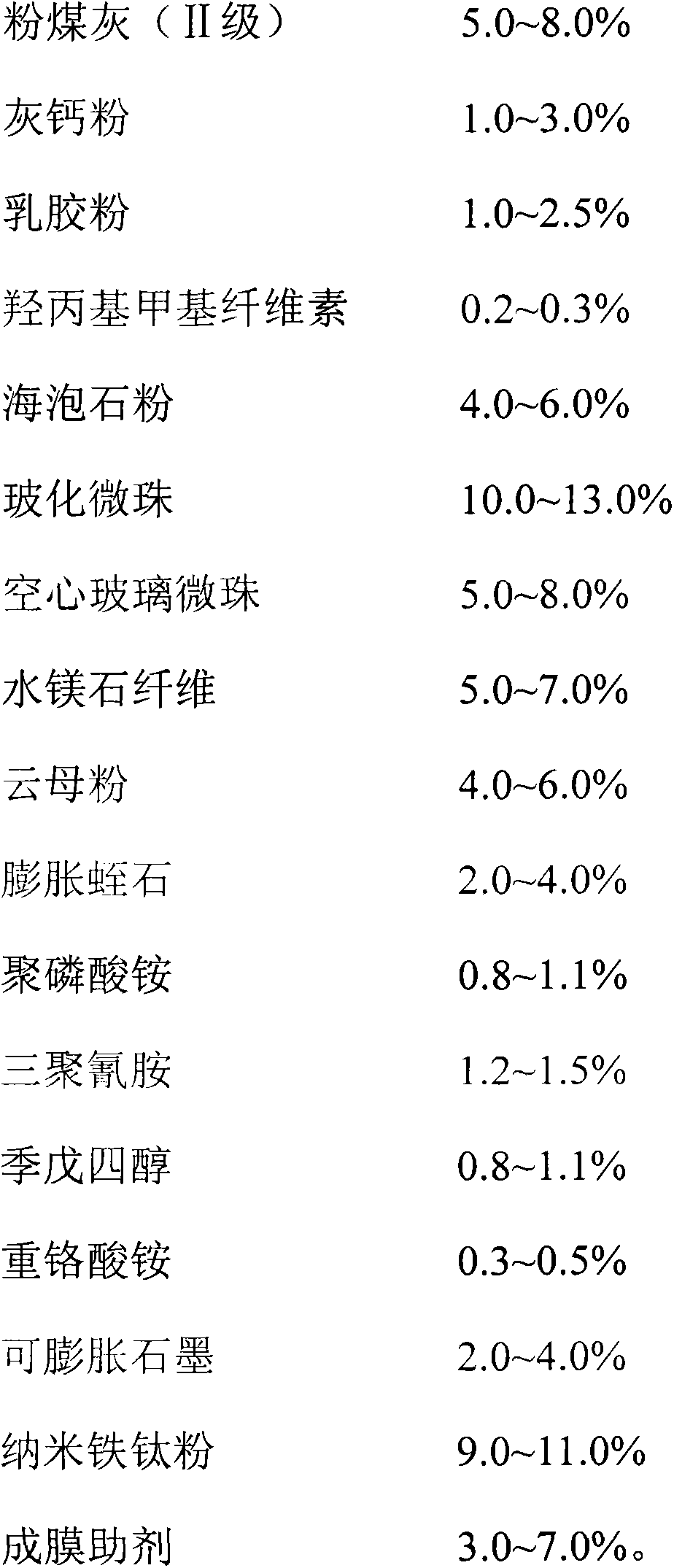

[0026] Hydrocarbon-resistant outdoor thick-coated steel structure fireproof coatings, the ratio of raw materials is calculated by weight percentage:

[0027]

[0028]

Embodiment 3

[0030] Hydrocarbon-resistant outdoor thick-coated steel structure fireproof coatings, the ratio of raw materials is calculated by weight percentage:

[0031]

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com