Patents

Literature

78 results about "Ammonium bichromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium dichromate is the inorganic compound with the formula (NH4)2Cr2O7. In this compound, as in all chromates and dichromates, chromium is in a +6 oxidation state, commonly known as hexavalent chromium. ... It is a salt consisting of ammonium ions and dichromate ions.

Tunnel fire retardant coating and preparation process and construction process thereof

InactiveCN101880145ASimple processImprove water retentionSolid waste managementPortland cementAluminum silicate

The invention provides a powdery mixture of a multi-component tunnel fire retardant coating, which is prepared from 582 resin, Portland cement, sepiolite, ammonium dichromate, light calcium carbonate, aluminum silicate, fly ash hollow floating beads, wollastonite powder, argil, cellulose ether, a concrete expanding agent, tin oxide and polypropylene fiber. The powdery mixture is prepared by throwing the fire retardant coating into a V-shaped forced mixer according to the proportion of the components; stirring the mixture for 10 to 15 minutes to prepare the powdery mixture; stirring water and the fire retardant coating powder in a weight ratio of 0.8-0.85 into thick paste; and spraying a tunnel from the waist to the top with spray painting equipment to reach the predetermined thickness.

Owner:成都威邦科技有限公司

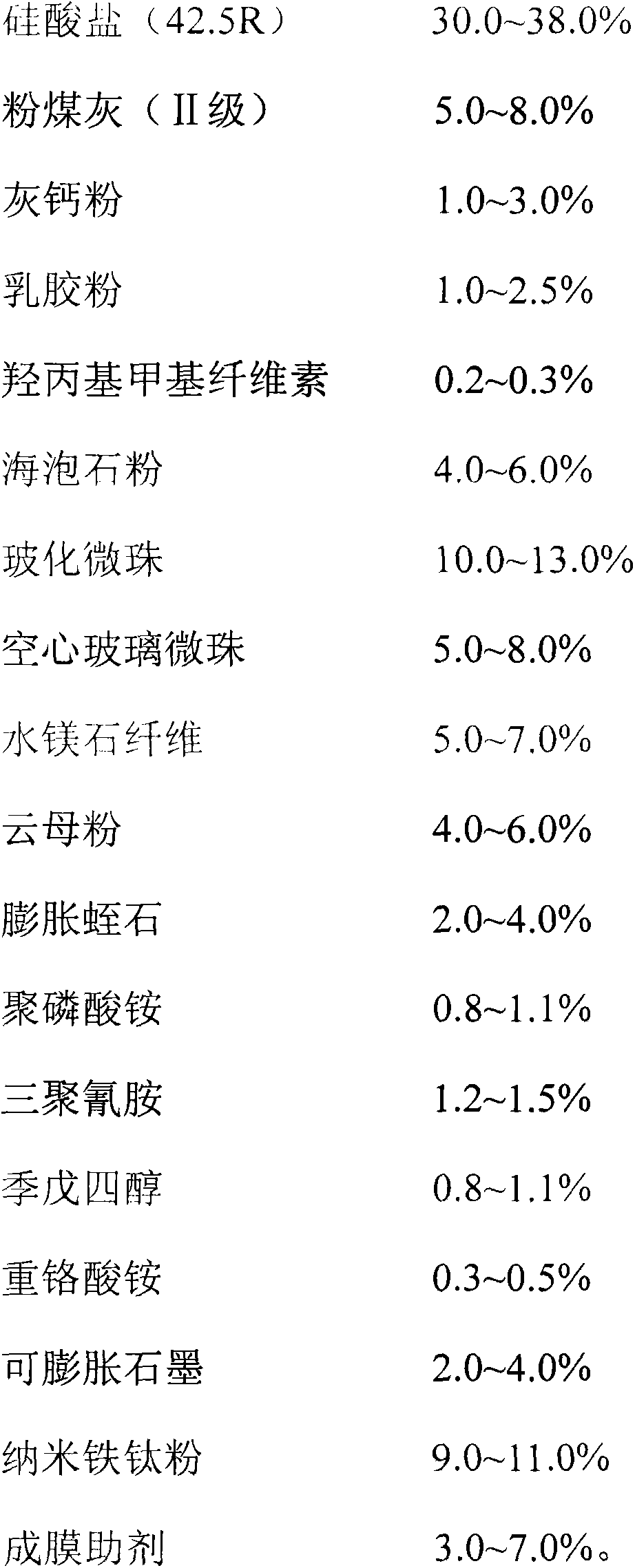

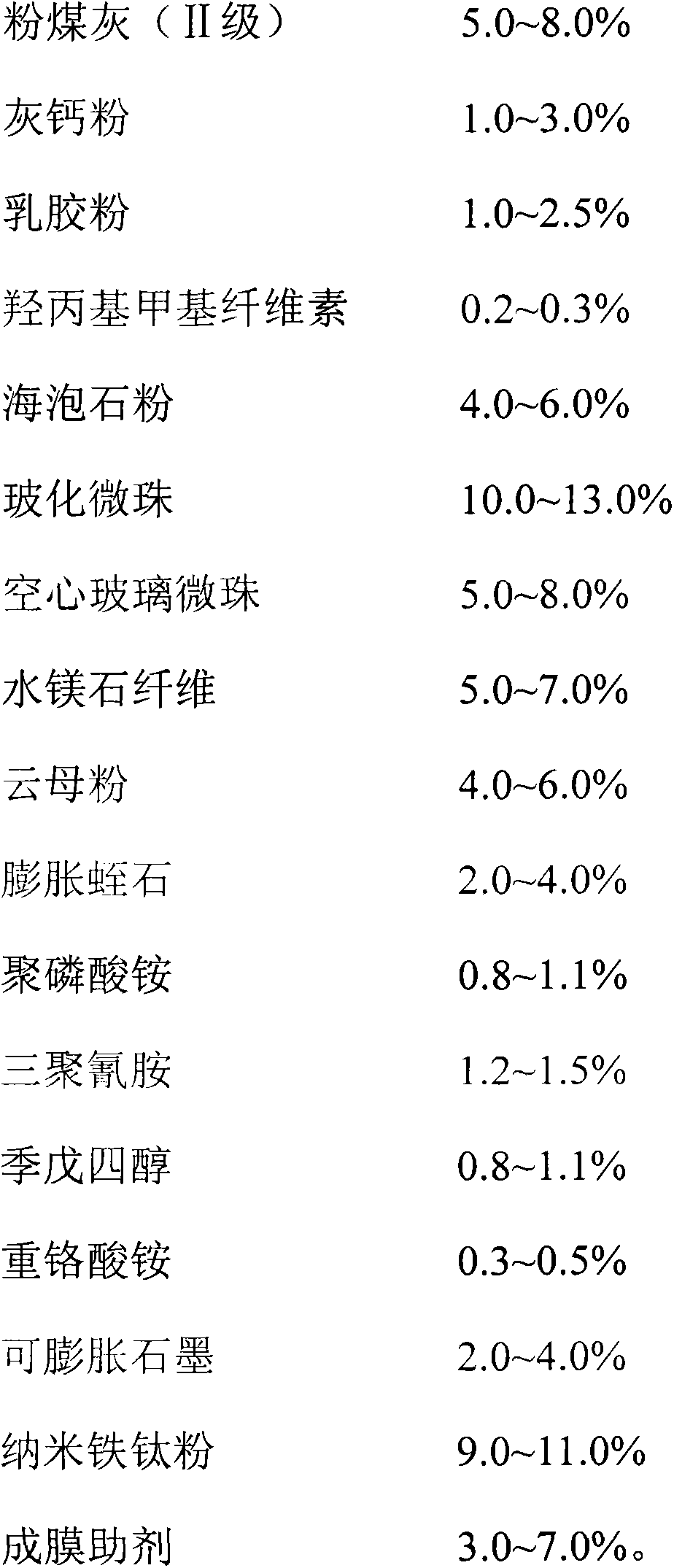

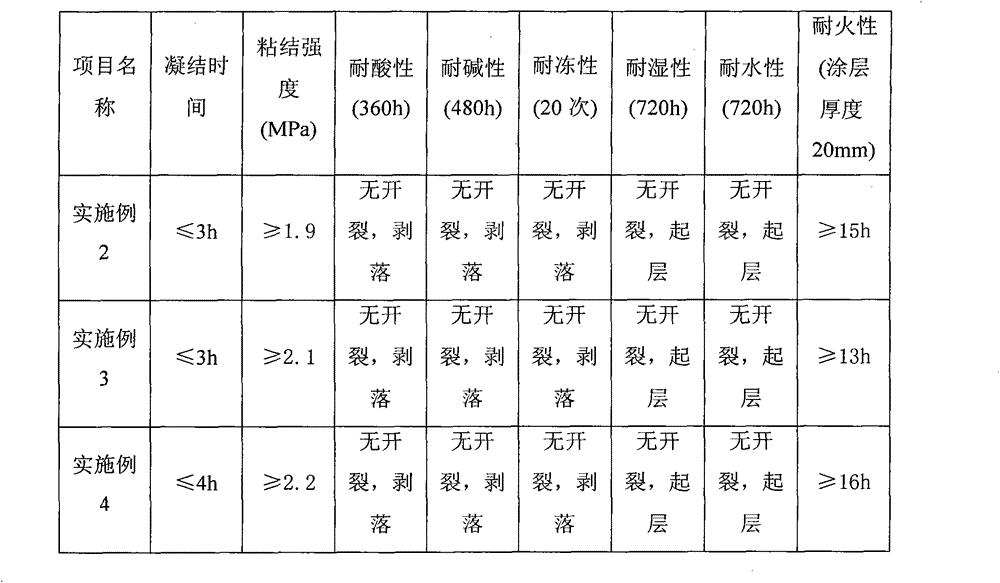

Hydrocarbon-resistant outdoor thick fireproofing coating for steel structures

ActiveCN103450716ALow thermal conductivityImprove fire and corrosion resistanceFireproof paintsAnti-corrosive paintsFiberFireproofing

The invention provides a hydrocarbon-resistant outdoor thick fireproofing coating for steel structures, wherein the fireproofing coating is prepared from the following raw materials in percentage by weight: 30.0-38.0% of silicate (42.5R), 5.0-8.0% of coal ash (II-grade), 1.0-3.0% of ash calcium powder, 1.0-2.5% of latex powder, 0.2-0.3% of hydroxypropyl methyl cellulose, 4.0-6.0% of sepiolite powder, 10.0-13.0% of glass beads, 5.0-8.0% of hollow glass beads, 5.0-7.0% of brucite fiber, 4.0-6.0% of mica powder, 2.0-4.0% of expanded vermiculite, 0.8-1.1% of ammonium polyphosphate, 1.2-1.5% of melamine, 0.8-1.1% of pentaerythritol, 0.3-0.5% of ammonium dichromate, 2.0-4.0% of expansible graphite, 9.0-11.0% of nano iron-titanium powder and 3-7% of a coalescing agent. The hydrocarbon-resistant outdoor thick fireproofing coating has binding strength, good water resistance and acid-base resistance property, and is safe and non-toxic, little in smoke, thermocycling resistant, excellent in corrosion resistance, and hydrocarbon fire resistant; the fireproofing coating can be widely used for fireproofing and anti-corrosion coating protection of indoor and outdoor steel structures.

Owner:石家庄雅致化工有限公司

Impervious tunnel fireproof paint

InactiveCN103641409AMake up for the defect of easy water seepageImprove adhesionCelluloseAluminium hydroxide

A disclosed impervious tunnel fireproof paint is prepared by stirring the following raw materials in parts by weight: 80-88 parts of refractory cement, 30-34 parts of portland cement, 20-30 parts of styrene acrylic emulsion, 30-35 parts of bisphenol epoxy resin emulsion, 6-8 parts of aluminium hydroxide, 10-11 parts of magnesium hydroxide, 10-14 parts of starch, 6-8 parts of ammonium bichromate, 6-8 parts of light calcium carbonate, 10-16 parts of ethyl cellulose, 5-9 parts of glass fibre, 14-18 parts of coal flying ash cenosphere, 3-5 parts of diatomite, 6-8 parts of vermiculite, 6-8 parts of mica, 6-8 parts of aluminum tripolyphosphate, 8-10 parts of potter's clay and 5-7 parts of pentaerythritol. The product provided by the invention not only is good in fireproof performance, but also has water seepage resistant performance, and thus makes up the disadvantage that the conventional fireproof paints are easily subjected to water seepage; and the fireproof paint is strong in caking property, easy to construct and operate and excellent in comprehensive performance, and is suitable for the fields such as traffic tunnels, people's air defence buildings, underground buildings and the like.

Owner:上海世范乐建新材料有限公司

Amino resin aqueous finishing coating

The invention discloses an amino resin aqueous finishing coating, which consists of the following components in percentage by weight: 50-65% of acrylic acid / epoxy / amino resin, 2-6% of triethylamine, 2-6% of ethylene glycol butyl ether, 18-26% of isopropyl alcohol, 0.2-1% of antifoaming agent, 0.2-1% of BYK-300, 0.06-0.1% of ammonium dichromate and 3-15% of pure water. The coating prepared depending on the above formula can be cured not only at high / medium temperature but at low temperature; the finishing coating disclosed by the invention can be used for coating electroplated workpieces, brass products, alloys and various metals and can be cured at low temperature; after spraying construction, the finishing coating can be completely cured within 10-20min at room temperature or at 60-110 DEG C; and after curing, the paint film has the advantages of being better in gloss, hardness and abrasion resistance, and excellent in scratching resistance effect.

Owner:YIYANG XIANGRUI TECH

Novel tunnel fireproof paint

InactiveCN103992670ALight weightGood fire resistance and heat insulationFireproof paintsAlkali metal silicate coatingsFiberRailway tunnel

The invention discloses a novel tunnel fireproof paint, belonging to the technical field of chemical engineering. The fireproof paint is prepared from the following components in parts by weight: 22-30 parts of water glass, 10-15 parts of silicate, 15-20 parts of styrene-acrylic emulsion, 3-5 parts of aluminum silicate fiber, 30-40 parts of magnesium hydroxide, 5-7 parts of tin oxide, 2-4 parts of ammonium borate, 10-12 parts of meerschaum, 25-27 parts of light calcium carbonate, 12-14 parts of expanded perlite, 10-11 parts of melamine, 3-5 parts of pentaerythritol, 3-4 parts of vermiculite, 1-3 parts of ammonium dichromate and 0.8-2 parts of dispersing agent. The tunnel fireproof paint has the advantages of light volume weight, favorable fire resistance, favorable heat insulation property, favorable water / acid / alkali resistance and the like, prevents the steel concrete in the tunnel from temperature drop due to quick temperature rise in a fire hazard, and prevents the concrete from bursting up. The tunnel fireproof paint is suitable for fireproof protection of highway tunnels and railway tunnels.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

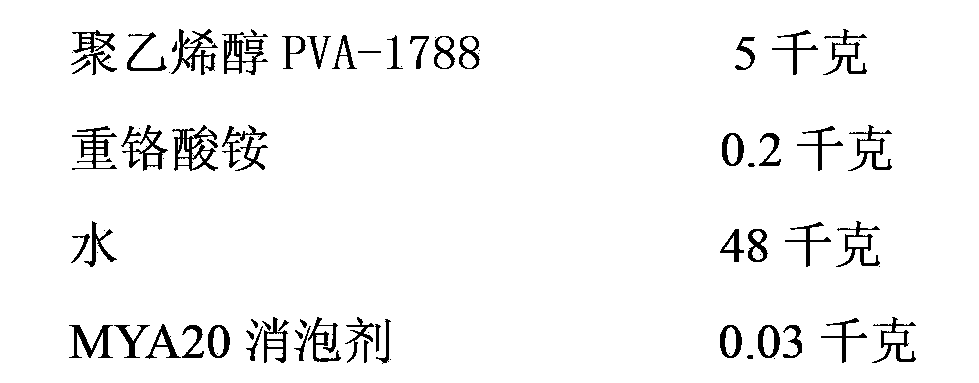

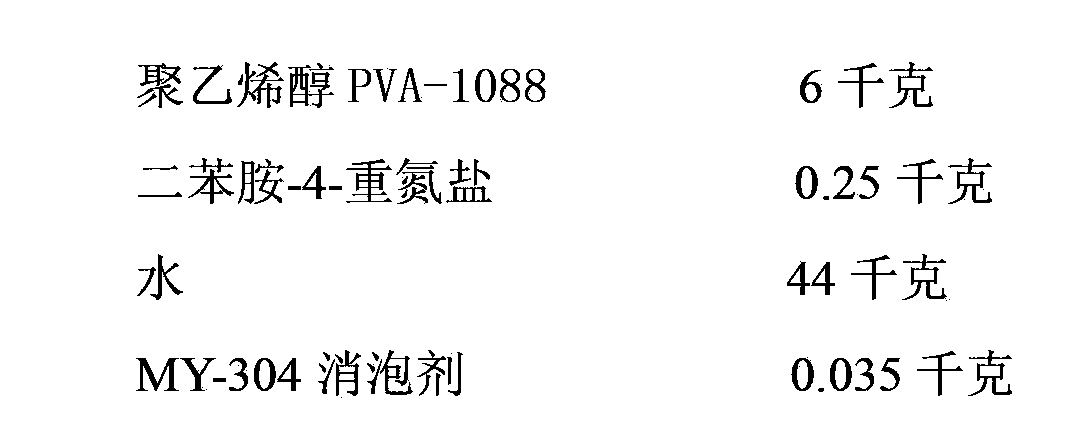

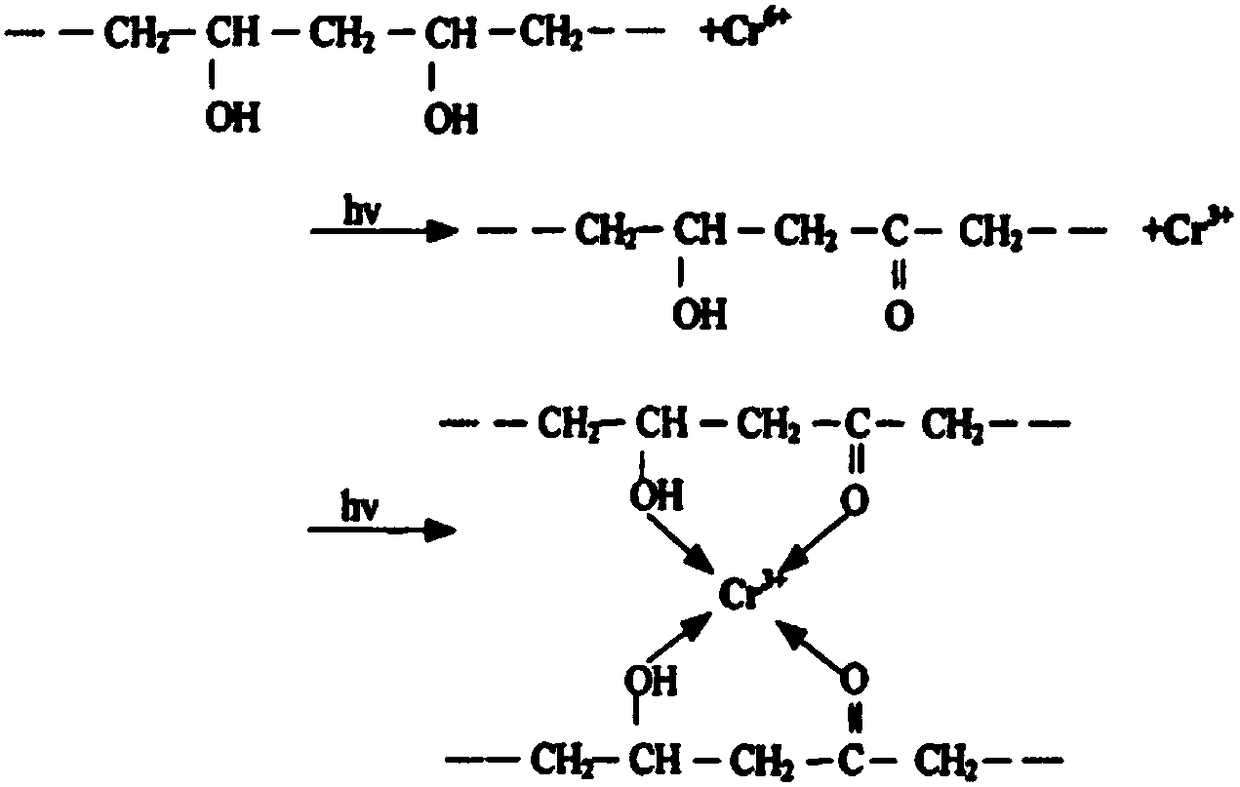

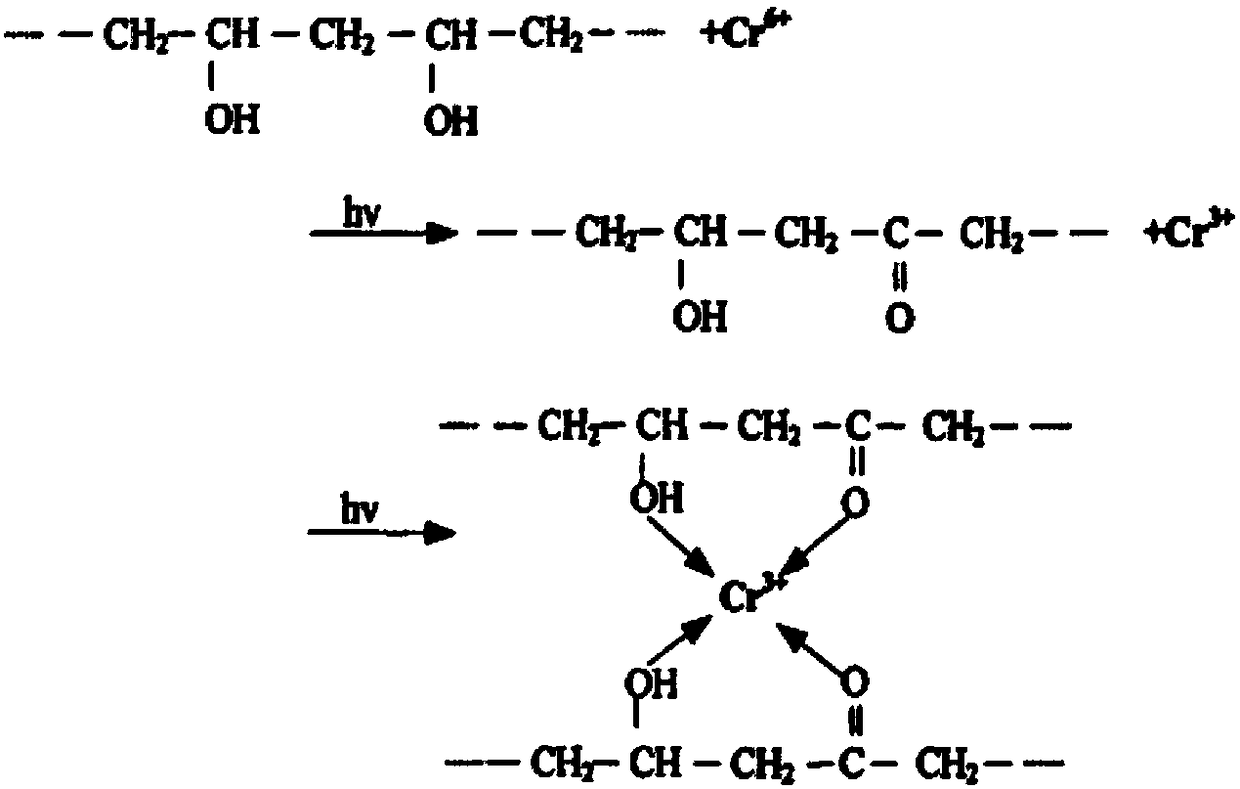

Polyol polymer photosensitive resist and preparation method thereof

ActiveCN103389619ALow viscosityReduce generationPhotosensitive materials for photomechanical apparatusResistWater based

A photosensitive resist is prepared through using 5-30 parts of a colloid, 0.1-0.7 parts of a photosensitive agent, 30-80 parts of water and 0.01-0.05 parts of an antifoaming agent; the colloid comprises one or more of polyvinyl alcohols having a polymerization degree of 300-2000 and an alcoholysis degree of 80-99mol%; the photosensitive agent is ammonium dichromate or comprises one or more of diazo compounds comprising diphenylamino-4-diazo salt, trimethoxy-4-diazodiphenylamino salt, a diphenylamino-4-diazo salt grafted compound, a trimethoxy-4-diazodiphenylamine compound, 2-diazo-1-naphthoquinone-4-sulfonyl chloride and the like and is processed to prepare an aqueous solution having a mass percentage concentration of 3-7%; and the antifoaming agent is a water-based organosilicon modified emulsion-like antifoaming agent. The obtained photosensitive resist has a lower viscosity than general photosensitive resists, steel band can be uniformly coated by the photosensitive resist, there are no spots after the coating of photosensitive resist on the steel band visually, and the technical problems of easy cracking, easy foaming and the like caused by the too high viscosity of present photosensitive resists in the subsequent application are effectively avoided.

Owner:CHINA PETROCHEMICAL CORP +1

Tunnel environment-friendly fireproof paint

A disclosed tunnel environment-friendly fireproof paint is mainly prepared by stirring the following raw materials in parts by weight: 30-35 parts of refractory cement, 30-35 parts of sulphoaluminate cement, 30-35 parts of AEC expansive cement, 30-35 parts of urea-formaldehyde resin, 10-16 parts of soybean oil fatty acid alkyd resin, 5-9 parts of magnesium hydroxide, 5-9 parts of aluminium hydroxide, 10-15 parts of meerschaum, 5-9 parts of perlite, 10-15 parts of ethyl cellulose, 6-10 parts of glass fiber, 8-11 parts of alumina silicate fiber, 5-7 parts of glass hollow floating beads, 4-8 parts of kaoline, 7-9 parts of vermiculite and 4-8 parts of ammonium bichromate. The paint provided by the invention is excellent in fireproof performance, corrosion resistance and stability, high in bonding strength, safe, nontoxic, short in curing time, convenient to construct and high in efficiency.

Owner:上海世范乐建新材料有限公司

High-efficient rust-proofing agent

InactiveCN1854345AImprove permeabilityAccelerated reduction reactionSodium molybdateSodium phosphates

A high efficient antirust which consists of the following component by weight ratio: water 200-300 share, orthophosphoric acid 80-160 share, sodium nitrate 0.5-4 share, zinc oxide 1-6 share, ammonium bichromate 1-5 share, tertiary sodium phosphate 1-8 share, sodium molybdate 0.01-1 share, hydroxypropyl methylcellulose 1-8 share, divinyl ether 1-4 share. It's high efficient antirust with great performance, strong penetrability and strong adhesive power.

Owner:晏雄立 +1

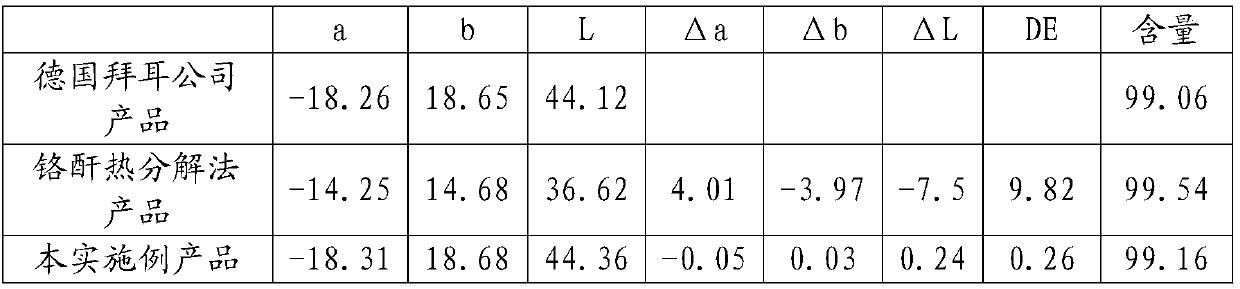

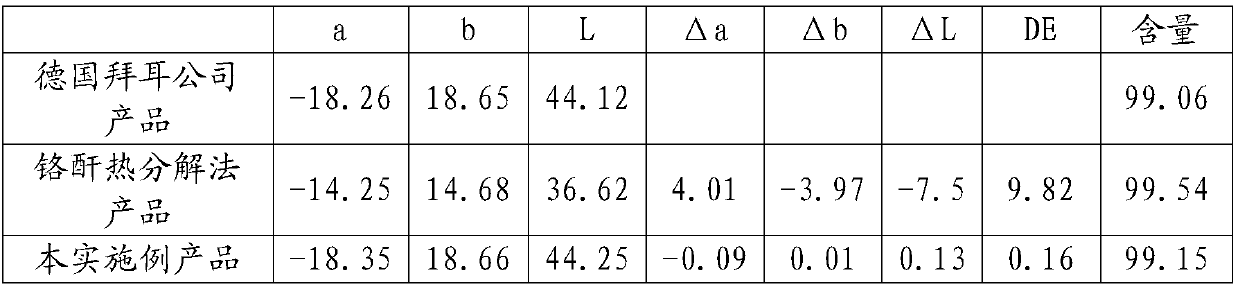

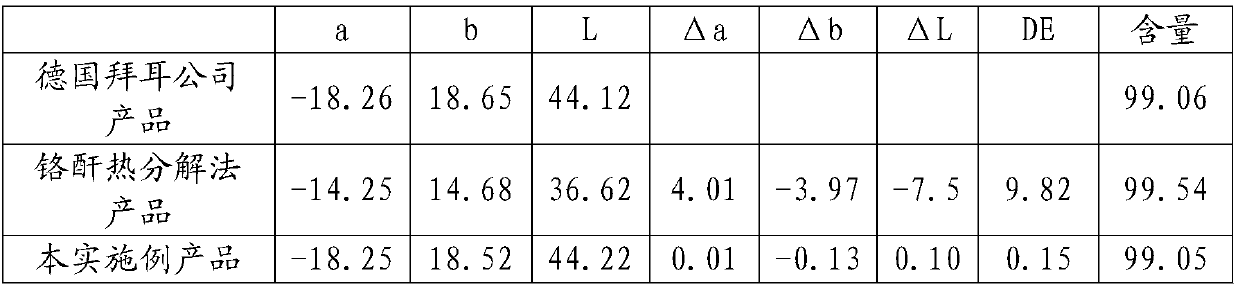

Production method of high-grade pigment chromium oxide green

ActiveCN108675353AConvenient sourceSimple production processChromium oxides/hydratesEnvironmental resistanceSodium sulfate

The invention discloses a production method f high-grade pigment chromium oxide green. According to the production method, sodium dichromate, ammonium sulfate (or ammonium carbonate) are taken as rawmaterials; crystallization technology is adopted to produce a ammonium dichromate and sodium sulfate (or sodium carbonate) mixed crystal, a roasting additive is added, high temperature roasting in a rotary kiln is carried out, and at last water washing impurity removing, drying, and crushing are carried out so as to obtain the chromium oxide green product. The beneficial effects are that: the uniformly reacted product is obtained through crystallization process, production and feeding are convenient; the production method is friendly to the environment, and no pollution is caused; the color ofthe obtained chromium oxide green product is more bright, colors close to yellow, close to green, and light color can be achieved, and product standards of Bayer company can be achieved, the productcan be used for replacing inported high-grade pigment chromium oxide green, the market prospect is promising, and the profit value is high.

Owner:GANSU JINSHI CHEM

Tear-resistant and good-leakproofness tire rubber material

The invention discloses a tear-resistant and good-leakproofness tire rubber material. The tear-resistant and good-leakproofness tire rubber material is prepared from, by weight, 15-25 parts of nitrile rubber, 4-12 parts of polybutadiene rubber, 20-35 parts of butadiene styrene rubber, 6-12 parts of chlorosulfonated polyethylene rubber, 0.5-1.7 parts of antioxidant A, 0.5-1.5 parts of oleic acid, 0.5-2.5 parts of stearic acid, 0.15-0.45 part of ammonium dichromate, 2-4 parts of dibenzothiazyl disulfide, 30-50 parts of modified bamboo fiber, 4-12 parts of nano-carbon black, 8-16 parts of nano-cellulose whiskers, 45-65 parts of nano-clay, 3-12 parts of corn straw fiber, 1-2 parts of octyl-phenolic tackifying resin, 4-12 parts of bamboo residue fiber, 0.4-1.6 parts of dibutyl phthalate, 0.7-1.3 parts of dioctyl sebacate and 0.6-1.2 parts of epoxy fatty acid methyl ester. The tear-resistant and good-leakproofness tire rubber material is good in rear resistance and anti-aging performance and excellent in sealing performance.

Owner:DELUN RUBBER

Preparation method of granite polishing powder

InactiveCN103937412ASmall median diameterNarrow particle size distributionPolishing compositions with abrasivesPlane surface grinding machinesAmmonium carbonateSlurry

The invention discloses a preparation method of granite polishing powder. The method is characterized in that the method comprises the following steps: dissolving 3-12% by mass of ammonium dichromate and 6-18% of zirconium oxychloride in water, adding 50-70% of alumina, adding 2-10% of titanium dioxide, adding 0.5-1% of a surfactant, stirring to form a slurry, adding 10-20% of ammonium carbonate, stirring for dissolving, stirring under normal pressure, heating to 70-75DEG C, reacting for 20-30h, evaporate to dryness, heating to 190-195DEG C, reacting for 2-4h, roasting at 1000-1100DEG C for 1-2h, cooling, and carrying out air flow crushing to obtain the granite polishing powder. The preparation method has the advantages of simplicity, easy condition control, low production cost, and easy industrialized production. The granite polishing powder is used for the granite polishing process, and has the advantages of good polishing effect, glossiness, small scratch quantity, high flatness, and small amount.

Owner:UNIV OF JINAN

Polyvinyl alcohol aqueous gravure UV ink connecting material and preparation method thereof

The invention discloses a polyvinyl alcohol aqueous gravure UV ink connecting material. The polyvinyl alcohol aqueous gravure UV ink connecting material comprises the following components: 4% to 10% of PVA17-99, 3% to 7% of an additive, 1% to 6% of ammonium dichromate, 3% to 4% of industrial ethanol, 70% to 85% deionized water, and less than 1% sodium nitrate. The invention also discloses a preparation method of the polyvinyl alcohol aqueous gravure UV ink connecting material. The method comprises the following steps: step 1, weighing the raw materials; step 2, preparing an ammonium dichromatesolution; step 3, preparing the PVA17-99 solution; and step 4, adding a remaining auxiliary. A photosensitive adhesive is prepared by the water-soluble polymer resin polyvinyl alcohol, a solvent is water, which is non-toxic, non-polluting, low in price, material acquisition is convenient, the photosensitive adhesive is used as the connecting material without solvent evaporation, and is safe and pollution-free. The production efficiency is high, the printing quality is excellent, the color saturation, color intensity and sharpness are obviously better than that of the common ink connecting material, and the UV ink connecting material is very beneficial for achieving healthy green printing.

Owner:XIAN UNIV OF TECH

High-tenacity waterproof silicone rubber material

The invention discloses a high-tenacity waterproof silicone rubber material which is prepared from the following raw materials in parts by weight: 20-60 parts of fluorinated silicone rubber, 20-40 parts of butyl rubber, 0.5-1.2 parts of a silane coupling agent KH550, 0.2-0.6 part of a coupling agent A-151, 20-40 parts of modified walnut shell fibers, 45-55 parts of barium metaborate, 2-8 parts of bentonite, 4-10 parts of bismuth oxide, 2-6 parts of boron oxide, 0.5-1.5 parts of dioctyl phthalate, 1-2 parts of trimethyl phosphate, 2-4 parts of di-tert-butyl peroxide, 0.2-0.6 part of ammonium dichromate potassium, 1-2 parts of titanium oxide acetylacetonate and 2-4 parts of an ultraviolet absorber UV-531. The high-tenacity waterproof silicone rubber material has excellent water resistance, tenacity and sealing property, excellent ageing resistance, good impact resistance and high hardness.

Owner:TIANCHANG KANGNING PLASTIC TECH

Seepage-resistant tunnel fireproof paint

InactiveCN103641497AMake up for the defect of poor waterproof functionSimple construction operationSlagCarvacryl acetate

A disclosed seepage-resistant tunnel fireproof paint is prepared by stirring the following raw materials in parts by weight: 100-105 parts of fireproof cement, 20-30 parts of portland blast furnace slag cement, 30-35 parts of acrylate polymer emulsion, 10-15 parts of vinyl acetate resin emulsion, 5-7 parts of aluminium hydroxide, 10-15 parts of perlite, 4-8 parts of fly ash, 3-4 parts of ammonium bichromate, 2-6 parts of light calcium carbonate, 10-16 parts of polypropylene short fiber, 2-6 parts of carboxymethyl cellulose, 7-9 parts of diatomite, 4-9 parts of vermiculite, 3-8 parts of ammonium polyphosphate, 5-8 parts of potter's clay and 3-5 parts of pentaerythritol. The product provided by the invention not only has good fireproof performance, but also has water seepage resistant performance, and thus makes up the disadvantage the conventional fireproof paints are bad in waterproof performance; and the fireproof paint is green, environment-friendly, strong in caking property, easy to construct and operate and excellent in comprehensive performance, and is suitable for the fields such as traffic tunnels, people's air defence buildings, underground buildings and the like.

Owner:江苏博思源防火材料科技有限公司

Improved mould-proof and waterproof coating

The invention discloses an improved mould-proof and waterproof coating, which is prepared from the following raw materials in parts by weight: 5-8 parts of ammonium dichromate, 1.2-2.7 parts of portland blast furnace slag cement, 0.8-1.6 parts of M-and P-cresols, 2.3-3.5 parts of rare earth drier, 2.5-5 parts of polyisocyanate, 1.2-2.3 parts of alkylphenol polyoxyethylene ether phosphate, 1.5-3.3 parts of ethyl phenyl-phenol-polyoxyethylene polyoxypropylene ether and 1.2-2.9 parts of benzyl-naphthalene sulfonic acid formaldehyde condensate dispersing agent. Compared with the existing waterproof coating, the improved mould-proof and waterproof coating has excellent waterproof and anti-permeability performances, can form a certain depth of ventilating hydrophobic film on an exterior wall of a building, can prevent invasion of water, simultaneously can play a mould-proof function on the wall body, has the characteristics of being small in ultraviolet effect, long in service life, good in durability and convenient to construct, and can be applicable to a plurality of construction sites.

Owner:广州市德鹏新材料科技有限公司

Poly(vinyl alcohol) waterborne intaglio printing UV ink and a preparation method thereof

Poly(vinyl alcohol) waterborne intaglio printing UV ink is disclosed. The ink includes, by mass, 3-9% of PVA17-99, 1-5% of ammonium bichromate, 10-15% of pigment, 4-7% of an auxiliary agent, 65-75% ofdeionized water, 3-4% of industrial ethanol, and less than 1% of sodium nitrate. The invention also discloses a preparation method of the ink. Printing with the ink meets the trend of increasing printing demands and continually increasing printer speeds. The ink is solvent-free ink, is low in pollution to air, eliminates damage of some harmful substances in solvent type ink to human and package printed products, improves the printing environment, and is an environmentally friendly product. The ink is not liable to burn, and is stable in ink property, bright in color, free of plate corrosion,simple to operate, low in material cost and good in adhesive force after printing, and a printing plate is easy to clean.

Owner:XIAN UNIV OF TECH

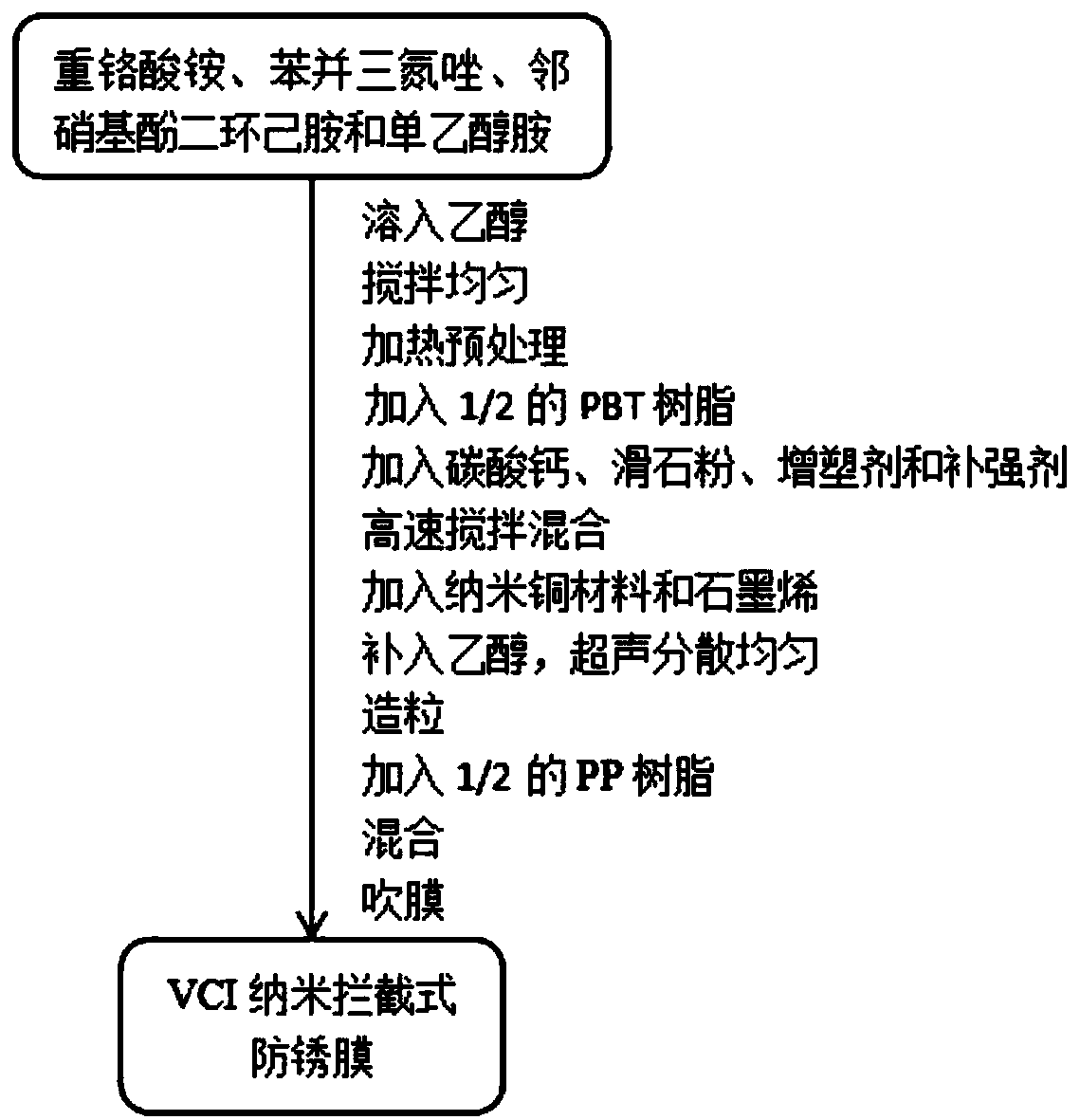

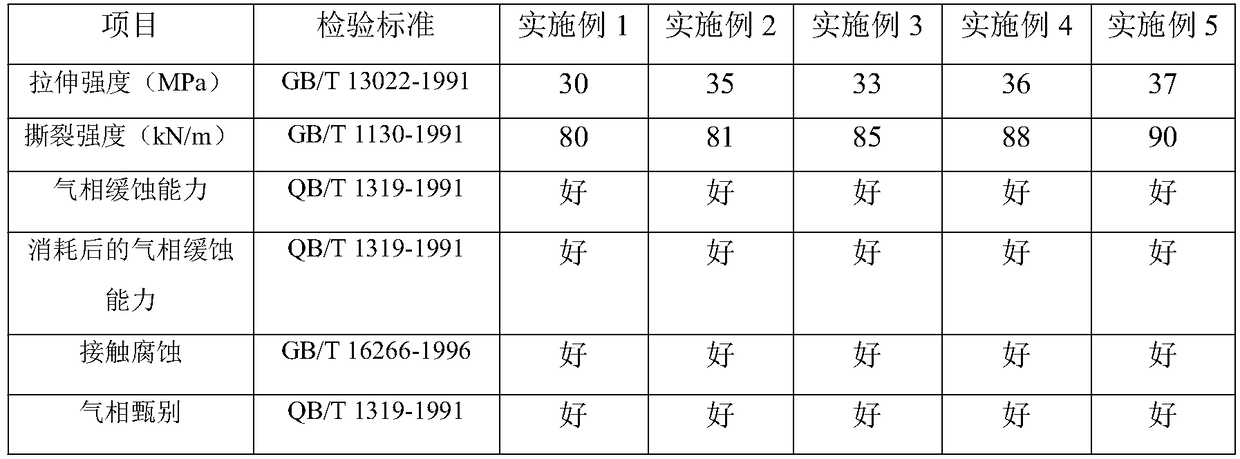

VCI nano intercept-type rust-proof film

The invention provides a VCI nano intercept-type rust-proof film. The rust-proof film is prepared from the following raw materials in parts by weight: 100-120 parts of PBT resin, 30-60 parts of a nano-copper material, 10-20 parts of graphene, 15-35 parts of ammonium dichromate, 10-20 parts of benzotriazole, 20-40 parts of o-nitrophenol dicyclohexylamine, 10-20 parts of monoethanolamine, 30-50 parts of calcium carbonate, 10-20 parts of talcum powder, 15-25 parts of a plasticizer, and 1-5 parts of a reinforcing agent. The rust-proof film is capable of solving problems that partial special products require a long rust protection period and anti-rust performance of a gas phase is not enough. A formed protective film is very thin and compact, a base color of steel is kept, and the double rust-proof protective effects are achieved.

Owner:VCI ANTIRUST NEW MATERIALS SHANGHAI

Fireproof coating for building

InactiveCN103146236AImprove fire resistanceReduce dry densityFireproof paintsCement coatingsPortland cementSprayer

The invention provides a fireproof coating for building. The coating is composed of portland cement, ammonium dichromate, light calcium carbonate, aluminium silicate, flyash hollow float beads, wollastonite in powder and compound in formula I. The coating is prepared by putting the components into a V-shaped forced mixer according to proportion to prepare the powdery mixer after stirring for 10-15 minutes, mixing the water with the fireproof coating powder in a weight ratio of 0.8-0.85, and stirring to form slurry. When the slurry is in use, spraying is carried out by using a sprayer from bottom to top starting from the top of the building to achieve a predetermined thickness.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

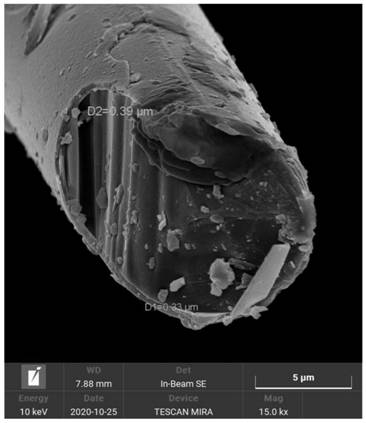

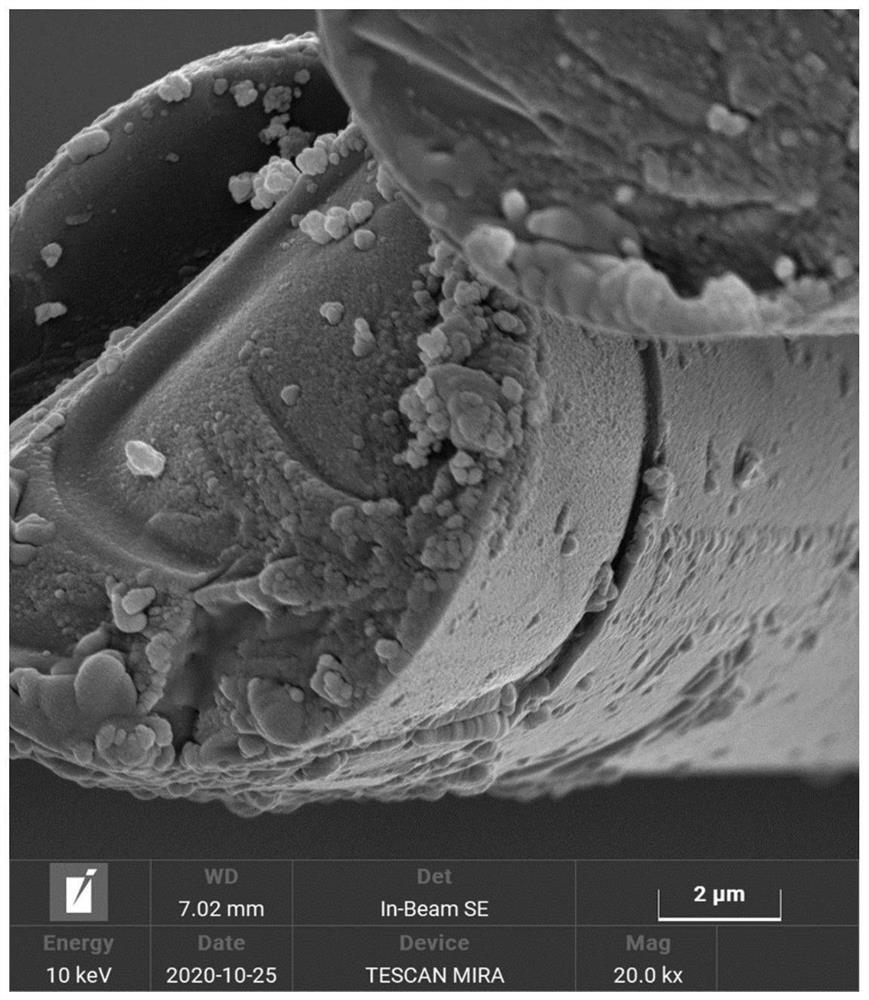

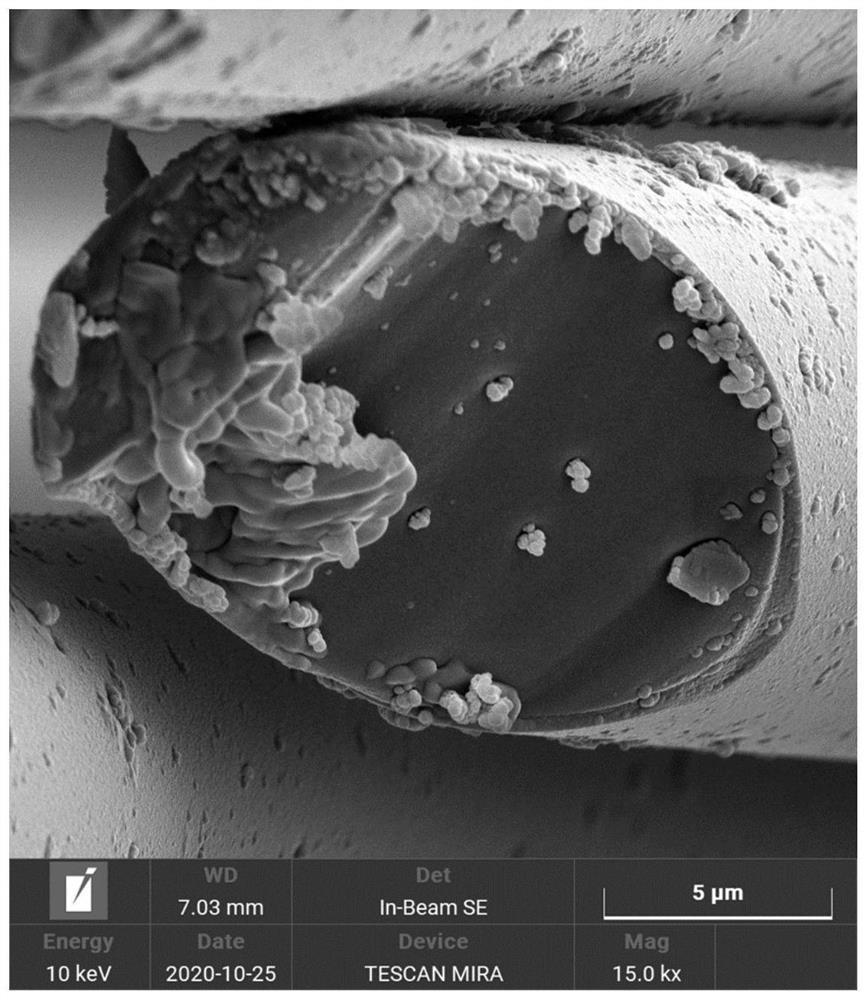

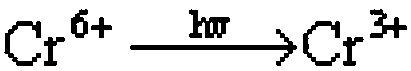

Preparation method of nano-Cr3C2 powder and application of nano-Cr3C2 powder to multi-element alloy coating

InactiveCN107176605AAbsorb evenlyUniform particle sizeCarbon compoundsNanotechnologyAmmonium dichromateFreeze-drying

The invention discloses a preparation method of nano-Cr3C2 powder and application of the nano-Cr3C2 powder to a multi-element alloy coating and belongs to the technical field of alloy materials. The preparation method of the nano-Cr3C2 powder, disclosed by the invention, comprises the following four steps: 1, mixing: putting ammonium dichromate powder and nano-carbon black powder into distilled water or de-ionized water; mixing and uniformly stirring until fluid is formed; adding the fluid into a mold and pressing and molding to form a precursor; 2, quickly freezing: rapidly transferring the precursor into a quick-freezing space for quickly freezing; 3, carrying out freeze-drying: rapidly transferring the quickly-frozen precursor into a vacuum freezing and drying cabin and carrying out the freeze-drying; 4, carbonizing: closing a cold trap of the vacuum freezing and drying cabin and gradually reducing high-valence oxide of chromium to low-valence oxide of chromium through carbon along with the rising of temperature, so as to prepare the multi-element alloy coating. The prepared multi-element alloy coating has the characteristics that the aims of heat-resisting and wear-resisting properties and high bonding strength are realized.

Owner:马鞍山华之智信息科技有限公司

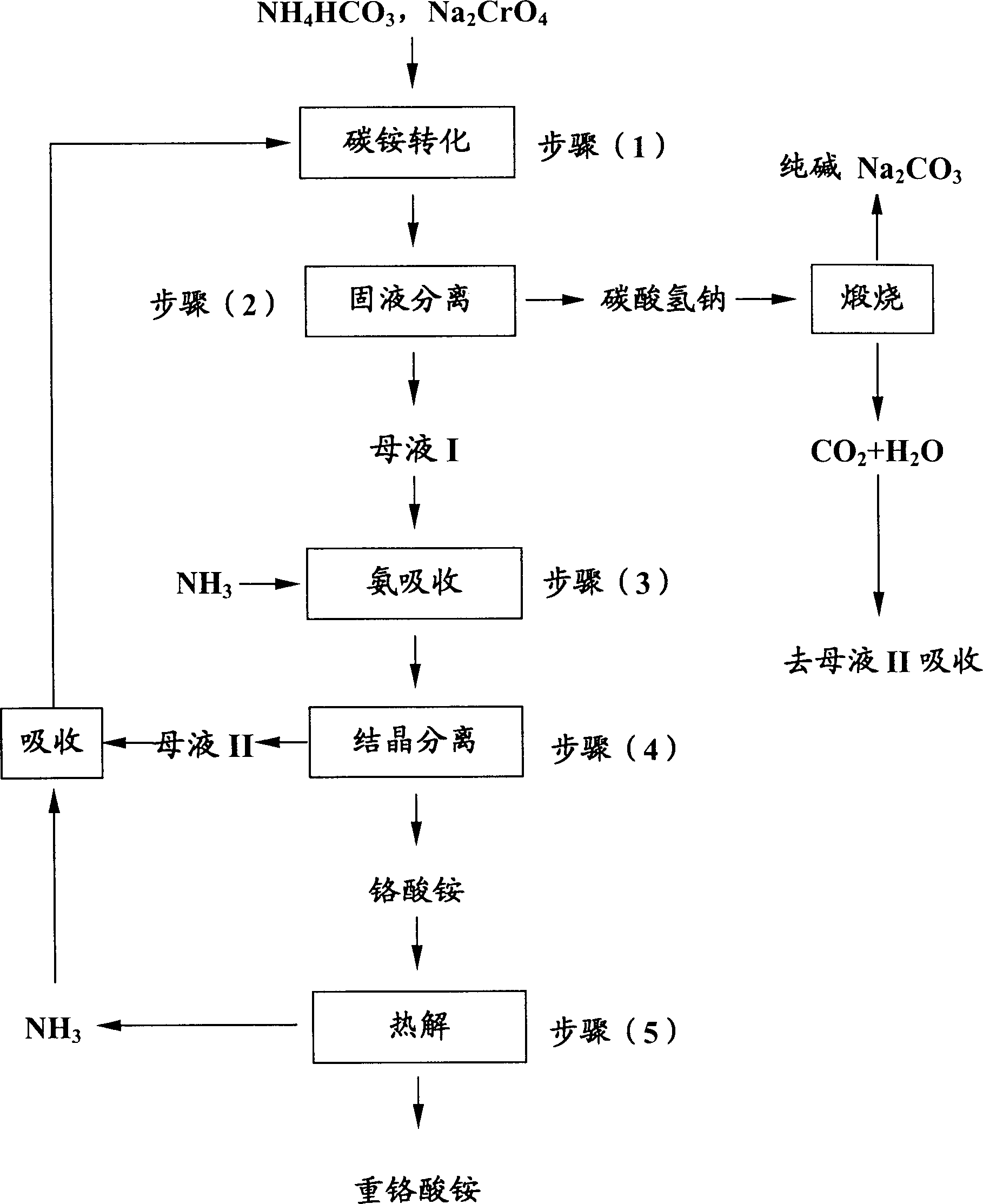

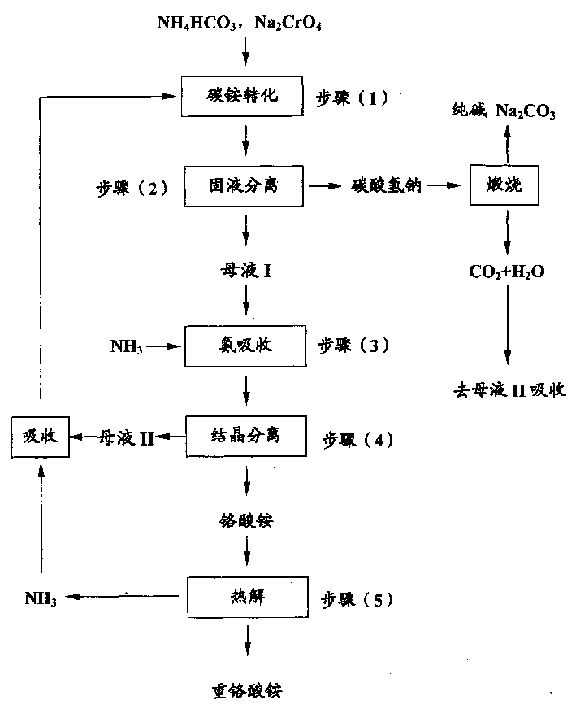

Process for preparing ammonium bichromate

InactiveCN1397499ARaw materials are cheap and easy to getSimple processChromates/bichromatesSodium bicarbonateSolubility

A process for preparing ammonium bichromate includes replacement reaction between sodium (or potassium) chromate and ammonium hydrogen carbonate in solution, solid-liquid separation to remove dicarbonate deposit, absorbing ammonia by mother liquid to convert the bicarbonate to high-solubility carbonate, cooling to educe out ammonium chromate, solid-liquid separation to collect ammonium chromate crystal, and pyrolyzing. Its advantages are simple process and no environmental pollution.

Owner:刘昌见

Waterproof cable with compact structure and small gap

InactiveCN106751853AGood mutual adsorptionHigh mechanical strengthRubber insulatorsFiberMethyl linoleate

The invention discloses a waterproof cable with a compact structure and a small gap. The cable comprises a conductor and a jacket layer covering the outer side of the conductor, wherein the jacket layer is prepared from the following raw materials in parts by weight: 26 to 32 parts of nitrile rubber, 20 to 35 parts of silicone rubber, 10 to 20 parts of chlorinated polyethylene, 1.5 to 2.5 parts of dicumyl peroxide, 1 to 2 aprts of N,N'-m-phenylenedimaleimide, 0.3 to 0.4 part of potassium ammonium dichromate, 0.4 to 0.8 part of poly-p-nitrosobenzene, 0.4 to 1.2 parts of dioctyl phthalate, 2 to 4 parts of bis(2-ethylhexyl) phthalate, 2 to 4 parts of chlorinated paraffin, 45 to 65 parts of white carbon black, 4 to 10 parts of diatomite, 8 to 12 parts of sepiolite, 10 to 18 parts of modified corn fibers, 1.5 to 2.5 parts of 2-ethylhexyl 9,10-epoxyoctadecanoate, 1.5 to 2.5 parts of epoxidized methyl linoleate, 1.5 to 2.5 parts of tributyl citrate, 8 to 16 parts of wheat protein, 1.5 to 3.5 parts of zinc stearate, 1 to 2 parts of antioxidant 264, and 2 to 3 parts of ultraviolet absorbent UV-531.

Owner:JINYUAN ELECTRIC GRP

Preparation method of high-temperature-resistant reinforced and toughened Ox/Ox composite material

ActiveCN112479691AHigh strengthImprove high temperature resistanceCeramicwareOxide ceramicOXALIC ACID DIHYDRATE

The invention discloses a preparation method of a high-temperature-resistant reinforced and toughened Ox / Ox composite material, and relates to the technical field of ceramic matrix composite materials. The method comprises the following steps: carrying out impregnation heat treatment pretreatment on an aluminum oxide fiber fabric by using a mixed solution of ammonium dichromate and anhydrous oxalic acid to obtain surface-coated aluminum oxide fibers, adding CVI to prepare a pyrolytic carbon coating layer or a BN coating layer, and carrying out electrophoretic deposition on the coating layer toobtain a nanowire coating layer; and coating the surface of the aluminum oxide fiber fabric with the nanowire coating layer with an aluminum oxide ceramic slurry, and carrying out hot pressing and sintering to obtain the high-performance Ox / Ox composite material. According to the preparation method of the high-temperature-resistant reinforced and toughened Ox / Ox composite material provided by theinvention, a high-density matrix and a microporous nano oxide coating layer are obtained, and a weak interface is formed between aluminum oxide fibers and an aluminum oxide matrix, so that the high-strength, high-toughness and high-temperature-resistant aluminum oxide fiber reinforced aluminum oxide matrix composite material is obtained.

Owner:CENT SOUTH UNIV

Water-based flexographic ultraviolet curing ink binder and preparation method thereof

The invention discloses a water-based flexographic ultraviolet curing ink binder. The water-based flexographic ultraviolet curing ink binder is prepared from 4%-10% of polyvinyl alcohol (PVA), 3%-7% of an auxiliary, 1%-6% of ammonium dichromate, 3%-4% of industrial alcohol, 70%-85% of deionized water and sodium nitrate less than 1%. The invention further discloses a preparation method of the water-based flexographic ultraviolet curing ink binder. The method comprises the steps that the PVA17-99 is prepared; the rest of the auxiliary is added. Photo-sensitive resist prepared from the water-soluble polymer resin polyvinyl alcohol uses water as solvent and is non-poisonous, pollution-free and low in price, materials are convenient to take, and when the photo-sensitive resist is used as the binder, no solvent volatilize, so that the photo-sensitive resist is safe and pollution-free; secondly, the production efficiency is high, the printing quality is excellent, the color saturation, the color intensity and the definition are obviously better than those of ordinary link binders, equipment is easy to clean, the photo-sensitive resist is very beneficial to achieving environment-friendly healthy and green printing, moreover, the photocuring speed of the photo-sensitive resist is improved, and thus the printing efficiency is improved.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

Good-airtightness anti-aging tire rubber material

The invention discloses a good-airtightness anti-aging tire rubber material. The good-airtightness anti-aging tire rubber material is prepared from the following raw materials in parts by weight: 25 to 35 parts of nitrile butadiene rubber, 2 to 8 parts of polyurethane, 12 to 16 parts of ethylene-propylene copolymer, 5 to 12 parts of phenolic resin, 0.2 to 0.6 part of ammonium dichromate, 1 to 2 parts of dibenzothiazyl disulfide, 0.5 to 1.5 parts of oleic acid, 1 to 2 parts of stearic acid, 20 to 30 parts of modified cotton fiber, 2 to 8 parts of kaolin, 5 to 10 parts of feldspar, 40 to 50 parts of lardite, 2 to 8 parts of limestone, 1 to 5 parts of apatite, 5 to 15 parts of ceramic microspheres, 1 to 3 parts of acetyl tributyl citrate, 1 to 2 parts of polyethylene wax, 1 to 2 parts of chlorinated paraffin, 0.5 to 1.5 parts of antioxidant AT-215, 1 to 2 parts of ultraviolet absorber UV-531 and 1 to 2 parts of ultraviolet absorber TB75. The good-airtightness anti-aging tire rubber material disclosed by the invention is good in tearing resistance, excellent in sealing performance and good in aging resistance.

Owner:DELUN RUBBER

Color filter solution for a cathode ray tube and method for patterning a color filter

A color filter solution for applying on a face glass of a cathode ray tube and a method for patterning a color filter to improve the brightness and contrast characteristics of the color filter. The color filter solution comprises a pigment, an anion surfactant which contains sodium or ammonium ion or citric acid as a dispersion agent, a mixture solvent of a glycol and a pyrrolidone containing methyl or ethyl, a nonionic surfactant and a pure water. A method for patterning a color filter in a cathode ray tube comprises the steps of: preparing a color filter solution which comprises a pigment, an anion surfactant which contains sodium or ammonium ion or citric acid as a dispersion agent, a mixture solvent of a glycol and a pyrrolidone containing methyl or ethyl, and a nonionic surfactant; forming a photoresist slurry by adding an alcohol-sodium or ammonium dichromate to the color filter solution ; and coating, exposing and developing the photoresist slurry on a face glass.

Owner:SAMSUNG ELECTRONICS DEVICES CO LTD

Seepage-proof and fire-proof coating for tunnels

InactiveCN105198334AMake up for the defect of poor waterproof functionImprove adhesionAluminium hydroxideBound property

The invention discloses a seepage-proof and fire-proof coating for tunnels. The coating is mainly prepared from raw materials in parts by weight as follows through stirring: 20-30 parts of white cement, 100-105 parts of sulfoaluminate cement, 30-35 parts of Portland cement, a bisphenol epoxy resin emulsion, 30-35 parts of a polyvinyl acetate emulsion, 6-8 parts of aluminium hydroxide, 6-8 parts of starch, 4-8 parts of ammonium dichromate, 5-9 parts of light calcium carbonate, 10-15 parts of hydroxypropyl methyl cellulose, 6-8 parts of hollow glass floating beads, 5-9 parts of kieselguhr, 10-14 parts of vermiculite, 5-9 parts of aluminium stearate, 10-14 parts of mica and 10-14 parts of argil. The coating has the good fire-proof performance, has the seepage-proof function, and overcomes the defect that traditional fire-proof coatings have poor water-proof functions; the fire-proof coating is environment-friendly, high in binding property, easy to construct and operate, excellent in comprehensive performance and applicable to fields of traffic tunnels, civil air defenses, underground buildings and the like.

Owner:杨金伟

Exterior wall anti-mildew waterproof coating material

InactiveCN103602167APrevent intrusionAnti-mildew effectCoatingsPhosphoric Acid EstersToluene diisocyanate

The present invention discloses an exterior wall anti-mildew waterproof coating material, which is prepared from the following raw materials by weight: 5-8 parts of ammonium dichromate, 1.2-2.7 parts of toluene diisocyanate, 0.8-1.6 parts of m-cresol and p-cresol, 2.3-3.5 parts of a rare earth drier, 2.5-5 parts of polyvinyl chloride, 1.2-2.3 parts of polyoxyethylene alkyphenol phosphorate, 1.5-3.3 parts of phenethyl phenol polyoxyethylene ether polyoxypropylene ether, and 1.2-2.9 parts of a benzyl naphthalene sulfonic acid formaldehyde condensation compound dispersing agent. Compared with the existing waterproof coating material, the exterior wall anti-mildew waterproof coating material of the present invention has excellent water resistance impermeability, can form an air-permeable hydrophobic film with a certain depth on the building exterior wall so as to prevent moisture from intrusion and further provide an effect of wall mildew resistance, has characteristics of less influence by ultraviolet light, long service life, good durability and easy construction, and can be applied for a variety of building sites.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

High-thrust fastener piece

InactiveCN108658711ASave metal materialImprove securityAmmonium perchlorate explosive compositionsPotassiumSolvent

The invention discloses a high-thrust fastener piece. The high-thrust fastener piece has characteristics of comprising components in parts by weight as follows: 5-10 parts of ammonium perchlorate, 5-10 parts of ammonium dichromate, 3-10 parts of potassium bichromate, 10-15 parts of SI powder, 40-65 parts of double-base powder and 45-75 parts of high-nitrogen nitro-cotton; the high-thrust fastenerpiece is prepared from the components by steps of removing water, adding a solvent for kneading, performing mechanical pressing in sequence and then performing drying, weighing and packaging to obtaina finished product. The high-thrust fastener piece has advantages of being convenient and fast to use and capable of executing construction operation without a power supply, completely replacing a metal fastener, saving electric power and labor force and being energy-saving, safe and reliable, and the problem of high labor intensity is solved.

Owner:浏阳象形精品烟花出口制造有限公司

Cable sheath material having cracking resistance and good thermal stability and used for wind power generation

InactiveCN106317522AGuaranteed hardnessImprove mixing dispersibilityInsulated cablesInsulated conductorsCrack resistanceMicrocrystalline wax

The invention a cable sheath material having cracking resistance and good thermal stability and used for wind power generation. The cable sheath material is prepared from raw materials in parts by weight as follows: 10-30 parts of phenyl siloxane rubber, 10-20 parts of nitrile rubber, 35-65 parts of styrene butadiene rubber, 1-2 parts of N,N'-m-phenylene dimaleimide, 1-2 parts of sodium ammonium dichromate, 2-4 parts of dicumyl peroxide, 10-15 parts of white carbon black, 45-65 parts of heavy calcium carbonate, 15-25 parts of bentonite, 15-23 parts of barite, 2-4 parts of palm wax, 2-5 parts of trioctyl phosphate, 1.5-2.5 parts of microcrystalline wax, 1.5-3 parts of dibutyl phthalate, 1-1.8 parts of epoxidized soybean oil, 1-2 parts of stearic acid and 2-4 parts of an antioxidant AT-215. The cable sheath material has good thermal stability and excellent mechanical properties and is aging-resistant.

Owner:ANHUI LAND GRP

Sound-absorbing and fireproof paint for tunnels

The invention discloses a sound-absorbing and fireproof paint for tunnels. The paint is mainly composed of the following raw materials in parts by weight: 55 to 65 parts of sulfoaluminate cement, 70 to 75 parts of fireproof cement, 20 to 30 parts of white and special blue cement, 20 to 30 parts of polyacrylic acid emulsion, 20 to 30 parts of polyvinyl acetate emulsion, 5 to 9 parts of magnesium hydroxide, 5 to 9 parts of aluminium hydroxide, 10 to 13 parts of perlite, 5 to 9 parts of fly ash, 5 to 8 parts of ethyl cellulose, 5 to 15 parts of glass fiber, 10 to 15 parts of glass hollow floating beads, 10 to 14 parts of diatomite, 8 to 10 parts of ammonium dichromate, 5 to 9 parts of mica, and 5 to 8 parts of pentaerythritol; and the paint is prepared by mixing and stirring the raw materials mentioned above according to the ratio. The sound-absorbing and fireproof paint has the advantages of long lasting fireproof effect, good adhesive performance, and convenience for construction; is suitable for various tunnel walls, and has a sound absorbing function on the basis of a fireproof function.

Owner:上海世范乐建新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com