VCI nano intercept-type rust-proof film

A nano and nano-copper technology, applied in the field of VCI nano interception anti-rust film, can solve the problems of poor resistance, reduced anti-rust effect, long anti-rust cycle, etc., to slow down the oxidation process, prevent rust, and have a high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

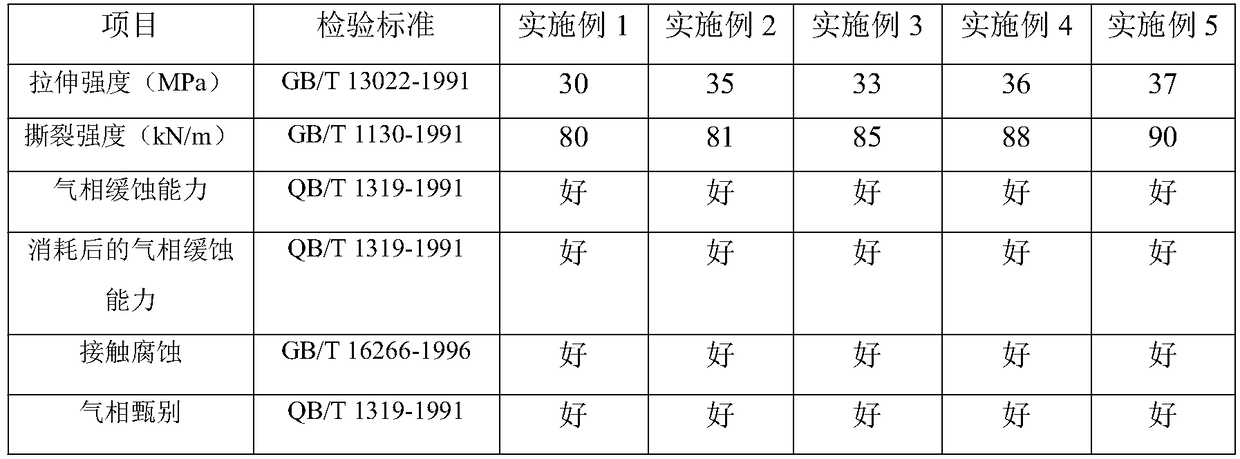

Embodiment 1V

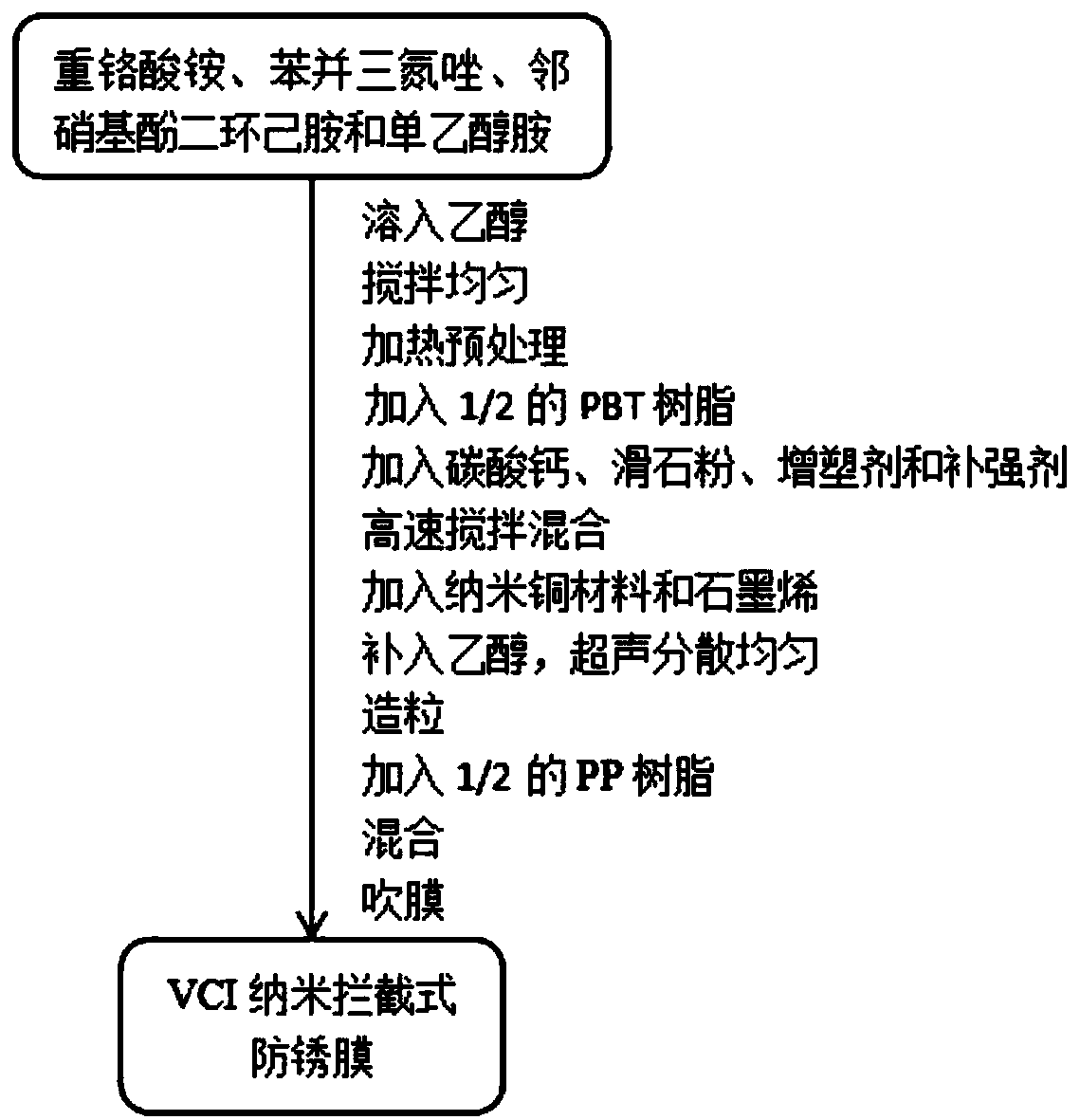

[0021] The preparation of embodiment 1VCI nano-intercepting type anti-rust film

[0022] Raw material composition:

[0023] 100 parts of PBT resin, 30 parts of nano copper material, 10 parts of graphene, 15 parts of ammonium dichromate, 10 parts of benzotriazole, 20 parts of o-nitrophenol dicyclohexylamine, 10 parts of monoethanolamine, 30 parts of calcium carbonate 10 parts of talcum powder, 15 parts of dioctyl phthalate, and 1 part of diatomaceous earth.

[0024] Preparation:

[0025] Mix ammonium dichromate, benzotriazole, o-nitrophenol dicyclohexylamine and monoethanolamine into ethanol, stir evenly, heat to 70°C for 30 minutes, add 1 / 2 of PBT resin, calcium carbonate, Talc powder, dioctyl phthalate and diatomaceous earth, stir and mix at high speed, continue to add nano-copper materials and graphene, add ethanol, ultrasonically disperse evenly, granulate, add 1 / 2 of PBT resin, mix, blow Film, that is.

[0026] Granulation process parameters: main machine speed 50r / min...

Embodiment 2V

[0028] The preparation of embodiment 2VCI nano interception type anti-rust film

[0029] Raw material composition:

[0030] 120 parts of PBT resin, 60 parts of nano copper material, 20 parts of graphene, 35 parts of ammonium dichromate, 20 parts of benzotriazole, 40 parts of o-nitrophenol dicyclohexylamine, 20 parts of monoethanolamine, 50 parts of calcium carbonate 20 parts of talcum powder, 25 parts of dicyclohexyl phthalate, 5 parts of white carbon black.

[0031] Preparation:

[0032] Mix ammonium dichromate, benzotriazole, o-nitrophenol dicyclohexylamine and monoethanolamine into ethanol, stir evenly, heat to 70°C for 60 minutes, add 1 / 2 of PBT resin, calcium carbonate, Talc powder, dicyclohexyl phthalate and white carbon black, stir and mix at high speed, continue to add nano-copper material and graphene, add ethanol, ultrasonically disperse evenly, granulate, add 1 / 2 of PBT resin, mix, Blown film, that is.

[0033] Granulation process parameters: main machine speed ...

Embodiment 3V

[0035] The preparation of embodiment 3VCI nano interception type anti-rust film

[0036] Raw material composition:

[0037] 105 parts of PBT resin, 35 parts of nano copper material, 12 parts of graphene, 20 parts of ammonium dichromate, 12 parts of benzotriazole, 25 parts of o-nitrophenol dicyclohexylamine, 12 parts of monoethanolamine, 35 parts of calcium carbonate 12 parts of talcum powder, 17 parts of diisodecyl phthalate, 2 parts of sulfur.

[0038] Preparation:

[0039]Mix ammonium dichromate, benzotriazole, o-nitrophenol dicyclohexylamine and monoethanolamine into ethanol, stir evenly, heat to 70°C for 40 minutes, add 1 / 2 of PBT resin, calcium carbonate, Talc powder, diisodecyl phthalate and sulfur, mixed at high speed, continue to add nano-copper material and graphene, add ethanol, ultrasonically disperse evenly, granulate, add 1 / 2 of PBT resin, mix, blow film , that is.

[0040] Granulation process parameters: main machine speed 50r / min, feeding speed 700r / min, pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com