Polyvinyl alcohol aqueous gravure UV ink connecting material and preparation method thereof

A technology of polyvinyl alcohol water-based and ink binder, which is applied in ink, household utensils, applications, etc. It can solve the problems of poor anti-adhesion, low drying rate, and poor water resistance, and achieve high production efficiency, convenient material acquisition, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

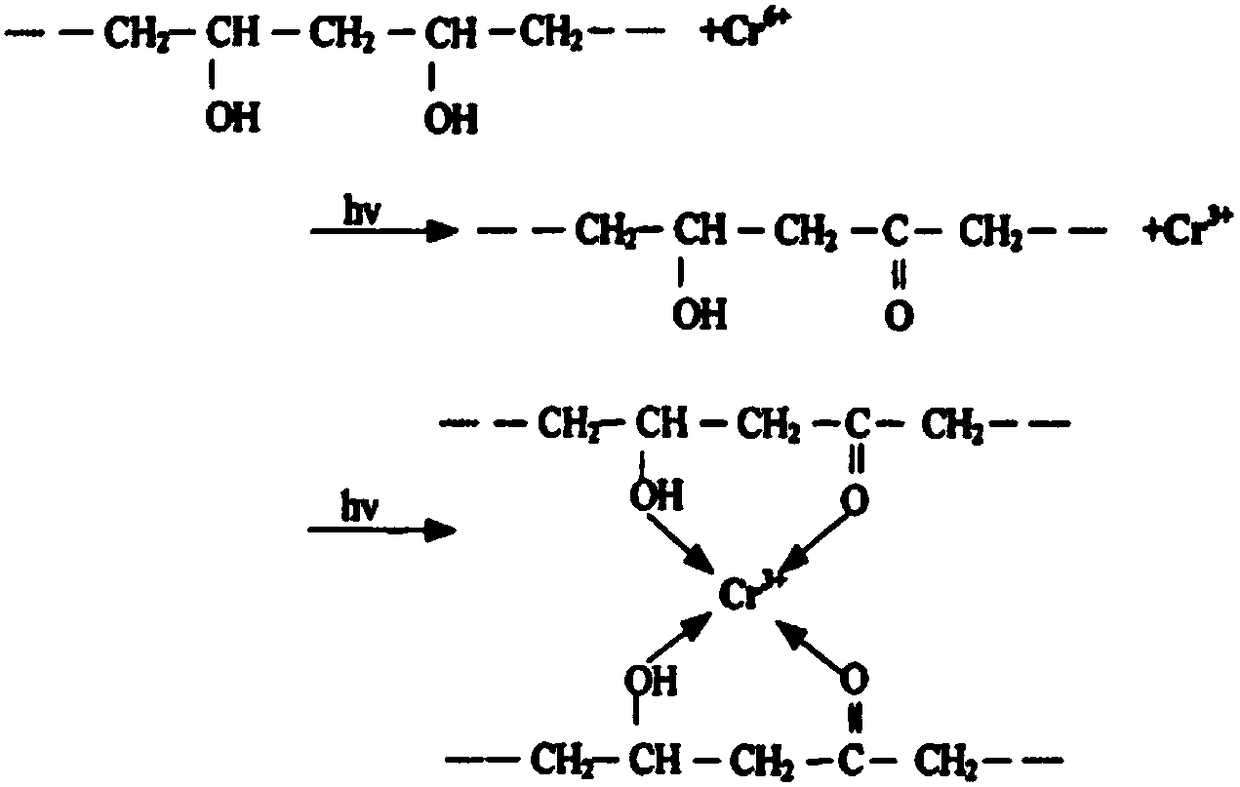

Method used

Image

Examples

Embodiment 1

[0052] This embodiment discloses a method for preparing a polyvinyl alcohol water-based gravure UV ink binder, which is specifically implemented according to the following steps:

[0053] Step 1, weigh raw materials

[0054] Weigh raw materials according to mass percentage: 75% of deionized water, 9% of PVA17-99, 3% of ammonium dichromate, 0.5% of sodium nitrate, 4% of industrial ethanol and 2% of boric acid. 1.5% TS-103 defoamer, 3% urea and 2% boric acid;

[0055] Step 2, prepare ammonium dichromate solution

[0056] Take 10% deionized water in step 1 by mass percentage, dissolve the ammonium dichromate taken in step 1 with the deionized water taken in step 2 and stir evenly to obtain ammonium dichromate solution;

[0057] Step 3, prepare PVA17-99 solution

[0058] Add the PVA17-99 weighed in step 1 into the mixer, and add the remaining deionized water in step 1 to the PVA17-99 weighed in step 1 while stirring under the condition that the mixer speed is 300r / min, so that ...

Embodiment 2

[0062] This embodiment discloses a method for preparing a polyvinyl alcohol water-based gravure UV ink binder, which is specifically implemented according to the following steps:

[0063] Step 1, weigh raw materials

[0064] Weigh raw materials according to mass percentage: 76% deionized water, 8% PVA17-99, 6% ammonium dichromate, 0.5% sodium nitrate, 3% industrial ethanol, 1.5% JN- 5 high-efficiency defoamer, 4% urea and 1% boric acid;

[0065] Step 2, prepare ammonium dichromate solution

[0066] Take by weighing 11% deionized water in step 1 by mass percentage, the ammonium dichromate taken in step 1 is dissolved with the deionized water taken in step 2 and stirred evenly to obtain ammonium dichromate solution;

[0067] Step 3, prepare PVA17-99 solution

[0068] Add the PVA17-99 weighed in step 1 into the mixer, and add the remaining deionized water in step 1 to the PVA17-99 weighed in step 1 while stirring under the condition that the mixer speed is 300r / min, so that PV...

Embodiment 3

[0072] This embodiment discloses a method for preparing a polyvinyl alcohol water-based gravure UV ink binder, which is specifically implemented according to the following steps:

[0073] Step 1, weigh raw materials

[0074] Weigh raw materials according to mass percentage: 80% deionized water, 7% PVA17-99, 3% ammonium dichromate, 0.5% sodium nitrate, 3.5% industrial ethanol, 1.5% TS- 103 defoamer, 2% urea and 2.5% boric acid;

[0075] Step 2, prepare ammonium chromate solution

[0076] Take by weighing 12% deionized water in step 1 by mass percentage, stir after the ammonium dichromate taken by step 1 is dissolved with the deionized water taken by step 2, and obtain ammonium dichromate solution;

[0077] Step 3, prepare PVA17-99 solution

[0078] Add the PVA17-99 weighed in step 1 into the mixer, and add the remaining deionized water in step 1 to the PVA17-99 weighed in step 1 while stirring under the condition that the mixer speed is 300r / min, so that the PVA17-99 Fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com