Polyol polymer photosensitive resist and preparation method thereof

A technology of photosensitive glue and photosensitive agent, which is applied in the field of photosensitive glue, can solve the problems of uneven coating, poor solubility, easy cracking and foaming of photosensitive glue, and achieve the goal of saving defoaming time, shortening dissolution time and reducing foam The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

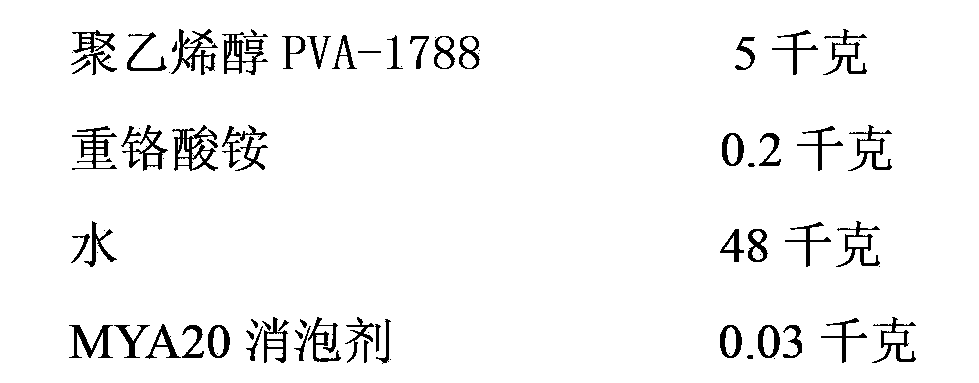

[0023] Weigh each substance as follows:

[0024]

[0025] First, slowly add polyvinyl alcohol PVA-1788 into a jacketed stirring tank with 30 kg of cold water, gradually raise the temperature to 80°C, then stir for 30 to 80 minutes to fully dissolve the polyvinyl alcohol, filter out impurities after dissolution, and cool for later use; Dissolve ammonium dichromate in the remaining water, filter out impurities, mix with dissolved polyvinyl alcohol solution in a preparation tank, add defoamer, and stand for 6-7 hours.

[0026] The photosensitive adhesive obtained above has a lower viscosity than the usual photosensitive adhesive, and is more evenly coated on the steel strip. The technical problems such as uneven coating, easy cracking and foaming caused by too high. The prepared photosensitive adhesive is used in the development process, and the uncured part after drying has good solubility, the development time is shortened by 30%, and the temperature of the developer is als...

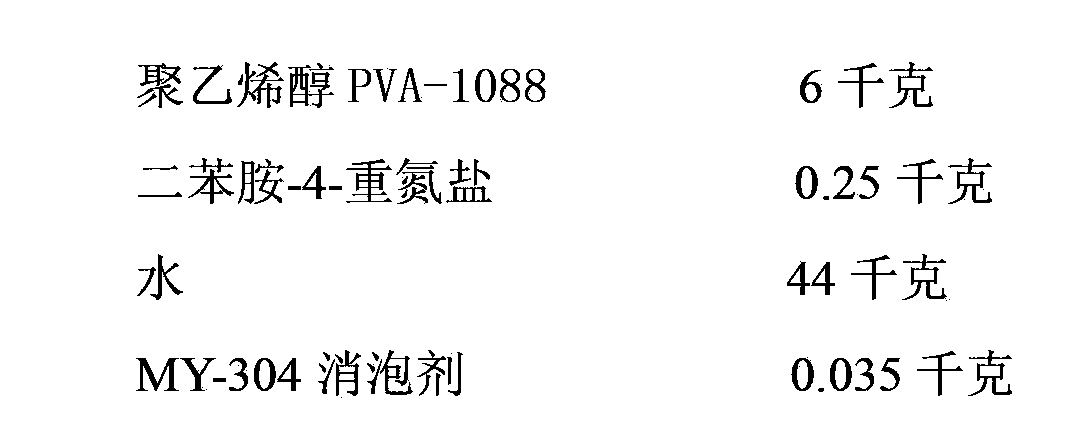

Embodiment 2

[0028]

[0029] Add 32kg of cold water into the stirring kettle, start stirring, then slowly add the polyvinyl alcohol PVA-1088 into the kettle, stir for about 5 minutes, raise the water temperature to 80°C within 10 minutes, keep stirring at a constant temperature of 60 Minutes, cool to get the colloid for use; dissolve ammonium dichromate in the remaining water, filter out impurities, mix with dissolved polyvinyl alcohol solution in the preparation tank, add defoamer, and stand for 4-5 Available in hours.

[0030] The photosensitive adhesive obtained above has a lower viscosity than the usual photosensitive adhesive, and is more evenly coated on the steel strip. The technical problems such as uneven coating, easy cracking and foaming caused by too high. The prepared photosensitive adhesive is used in the development process, and the uncured part after drying has good solubility, the development time is shortened by 50%, and the temperature of the developer is also approp...

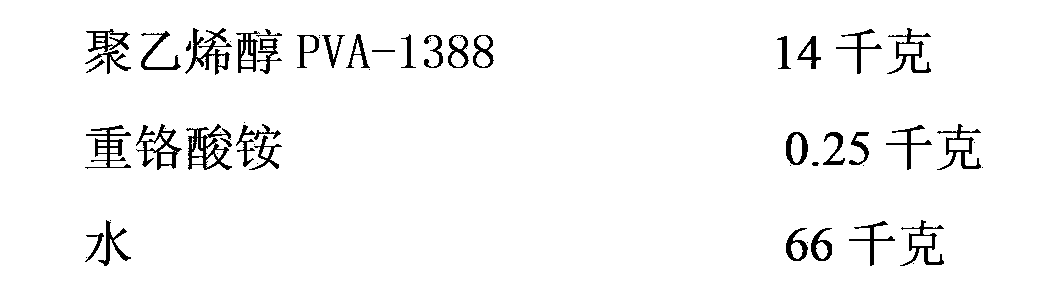

Embodiment 3

[0032]

[0033]

[0034] First, slowly add polyvinyl alcohol PVA-1388 into a jacketed stirring tank with 50 kg of cold water, gradually raise the temperature to 85°C, and then stir for 80 minutes to fully dissolve the polyvinyl alcohol. After the dissolution is completed, filter out impurities and cool for later use; Dissolve ammonium chromate in the remaining water, filter out impurities, mix with dissolved polyvinyl alcohol solution in a preparation tank, add defoamer, and let it stand for 5 hours.

[0035] The photosensitive adhesive obtained above has a lower viscosity than the usual photosensitive adhesive, and is more evenly coated on the steel strip. The technical problems such as uneven coating, easy cracking and foaming caused by too high. During the development process of the prepared photosensitive adhesive, the uncured part after drying has good solubility, the development time is shortened by 40%, and the temperature of the developer is also appropriately re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com