Water-based flexographic ultraviolet curing ink binder and preparation method thereof

A technology of ink binder and ultraviolet light, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of poor anti-adhesion, poor water resistance, and low drying rate, and achieve the effects of low cost, high production efficiency, and convenient material acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

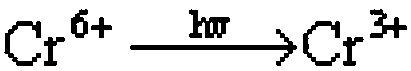

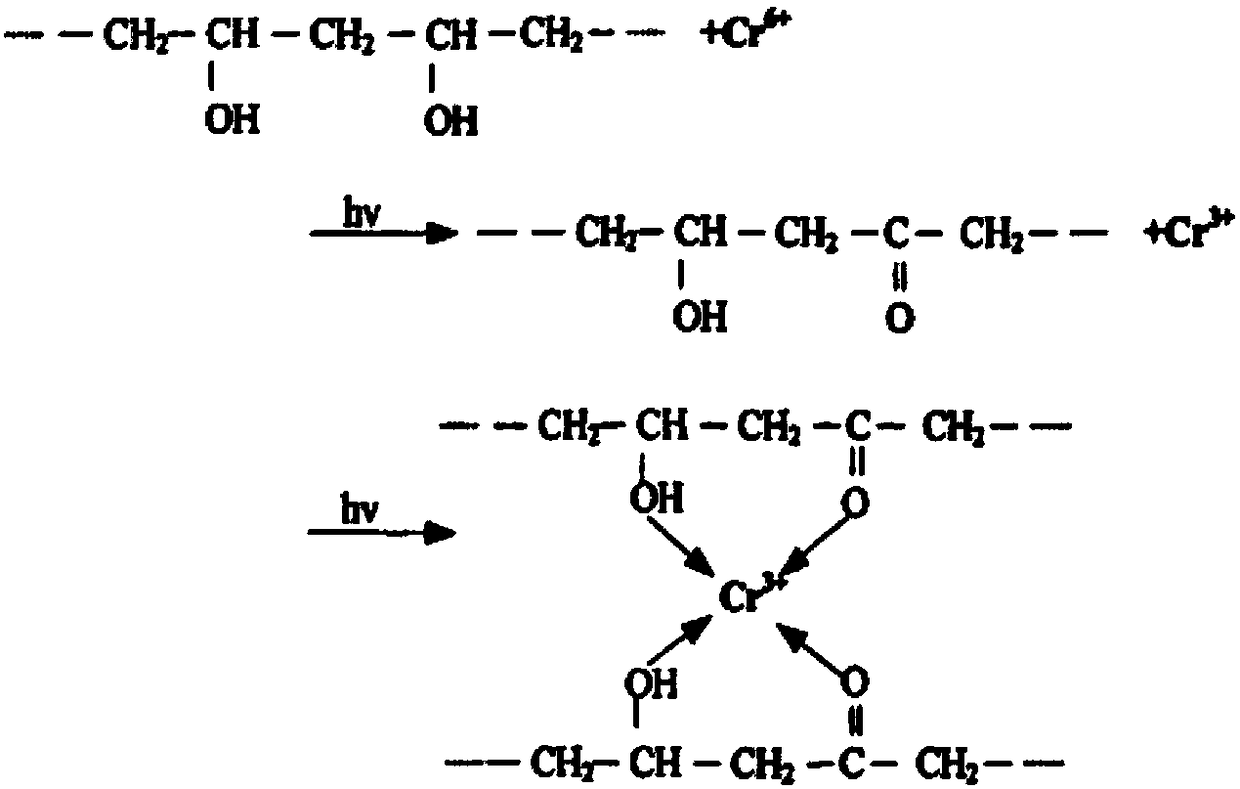

Method used

Image

Examples

Embodiment 1

[0033] A water-based flexo UV curable ink binder, composed of the following components by mass percentage: 77% deionized water, 9% PVA17-99, 3% ammonium dichromate, 0.5% sodium nitrate, 4% Industrial ethanol, 1.5% TS-103 defoamer, 3% urea and 2% boric acid.

[0034] A kind of preparation method of above-mentioned water-based flexo printing ultraviolet curable ink binder, comprises the following steps:

[0035] Step 1, weigh raw materials

[0036] Weigh raw materials according to mass percentage: 77% deionized water, 9% PVA17-99, 3% ammonium dichromate, 0.5% sodium nitrate, 4% industrial ethanol, 1.5% TS-103 defoaming agent, 3% urea and 2% boric acid.

[0037] Step 2, prepare PVA17-99 solution

[0038] Dissolve ammonium dichromate in deionized water and stir evenly to obtain ammonium dichromate solution. Slowly add PVA17-99 to ammonium dichromate at 20°C while stirring at a speed of 300r / h. Make it fully swell and disperse in the solution, and let the volatile substances es...

Embodiment 2

[0042] A water-based flexographic UV curing ink binder, composed of the following components by mass percentage: 76% deionized water, 8% PVA17-99, 6% ammonium dichromate, 0.5% sodium nitrate, 3% Industrial ethanol, 1.5% JN-5 high-efficiency defoamer, 4% urea and 1% boric acid.

[0043] A kind of preparation method of above-mentioned water-based flexo printing ultraviolet curable ink binder, comprises the following steps:

[0044] Step 1, weigh raw materials

[0045]Weigh raw materials according to mass percentage: 76% deionized water, 8% PVA17-99, 6% ammonium dichromate, 0.5% sodium nitrate, 3% industrial ethanol, 1.5% JN-5 high-efficiency disinfectant Foaming agent, 4% urea and 1% boric acid.

[0046] Step 2, prepare PVA17-99 solution

[0047] Dissolve ammonium dichromate in deionized water and stir evenly to obtain ammonium dichromate solution. Slowly add PVA17-99 to ammonium dichromate at 20°C while stirring at a speed of 300r / h. Make it fully swell and disperse in the ...

Embodiment 3

[0051] A water-based flexo printing ultraviolet curing ink binder, composed of the following components by mass percentage: 80% deionized water, 7% PVA17-99, 3% ammonium dichromate, 0.5% sodium nitrate, 3.5% Industrial ethanol, 1.5% TS-103 defoamer, 2% urea and 2.5% boric acid.

[0052] A kind of preparation method of above-mentioned water-based flexo printing ultraviolet curable ink binder, comprises the following steps:

[0053] Step 1, weigh raw materials

[0054] Weigh raw materials according to mass percentage: 80% deionized water, 7% PVA17-99, 3% ammonium dichromate, 0.5% sodium nitrate, 3.5% industrial ethanol, 1.5% TS-103 defoaming agent, 2% urea and 2.5% boric acid.

[0055] Step 2, prepare PVA17-99 solution

[0056] Dissolve ammonium dichromate in deionized water and stir evenly to obtain ammonium dichromate solution. Slowly add PVA17-99 to ammonium dichromate at 20°C while stirring at a speed of 300r / h. Make it fully swell and disperse in the solution, and let t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com